Are you gearing up for an interview for a Corrugated Fastener Driver position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Corrugated Fastener Driver and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

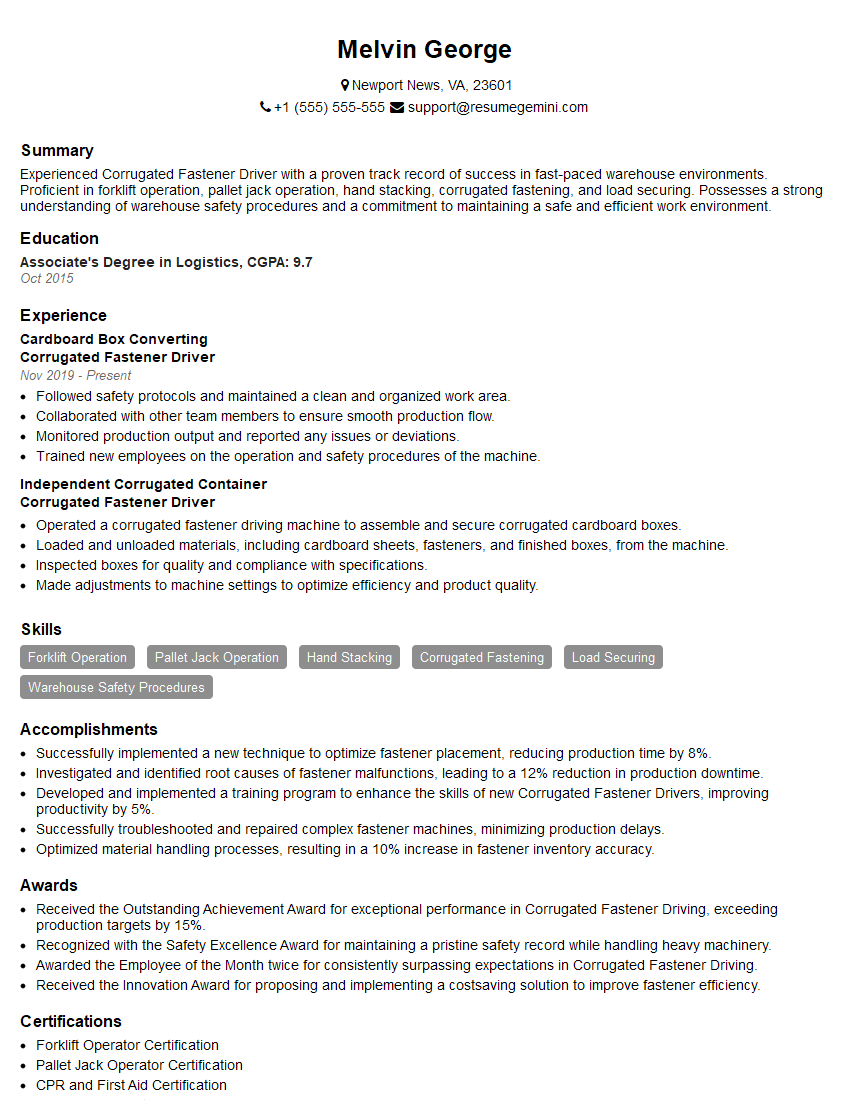

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Corrugated Fastener Driver

1. How do you ensure that the corrugated fasteners are properly driven and secure?

- First, I inspect the fasteners to make sure they are the correct size and type for the application.

- Then, I use a pneumatic nailer or stapler to drive the fasteners into the corrugated cardboard.

- I take care to drive the fasteners straight and flush with the surface of the cardboard.

- Finally, I inspect the finished product to make sure that the fasteners are secure and that the cardboard is not damaged.

2. What are the different types of corrugated fasteners and when should each type be used?

Different types of Corrugated Fasteners

- Staples: Staples are the most common type of corrugated fastener. They are made of metal and have two pointed legs that are driven into the cardboard.

- Nails: Nails are another type of corrugated fastener. They are made of metal and have a pointed end that is driven into the cardboard.

- Screws: Screws are a type of corrugated fastener that is made of metal and has a threaded shaft. The shaft is driven into the cardboard, and the threads hold the fastener in place.

When to use each type of fastener

- Staples: Staples are the best choice for light-duty applications, such as securing labels or posters to cardboard.

- Nails: Nails are a good choice for medium-duty applications, such as securing boxes or crates.

- Screws: Screws are the best choice for heavy-duty applications, such as securing pallets or crates.

3. What are the safety precautions that you take when driving corrugated fasteners?

- I always wear safety glasses when driving corrugated fasteners.

- I make sure that the nailer or stapler is in good working condition.

- I never point the nailer or stapler at anyone.

- I always keep my fingers away from the moving parts of the nailer or stapler.

- I never leave the nailer or stapler unattended.

4. What are the different types of corrugated cardboard and how do they affect the type of fasteners that you use?

- Single-wall corrugated cardboard: Single-wall corrugated cardboard is the most common type of corrugated cardboard. It consists of two flat sheets of paper with a corrugated sheet sandwiched between them.

- Double-wall corrugated cardboard: Double-wall corrugated cardboard is made of three sheets of paper with two corrugated sheets sandwiched between them.

- Triple-wall corrugated cardboard: Triple-wall corrugated cardboard is made of four sheets of paper with three corrugated sheets sandwiched between them.

The type of corrugated cardboard that you use will affect the type of fasteners that you need to use.

- Single-wall corrugated cardboard: Staples are the best choice for securing single-wall corrugated cardboard.

- Double-wall corrugated cardboard: Nails or screws are the best choice for securing double-wall corrugated cardboard.

- Triple-wall corrugated cardboard: Screws are the best choice for securing triple-wall corrugated cardboard.

5. How do you troubleshoot a corrugated fastener driver that is not working properly?

- Check the power source: Make sure that the driver is plugged into a power outlet and that the power switch is turned on.

- Check the air pressure: If the driver is pneumatic, make sure that the air pressure is set to the correct level.

- Check the fasteners: Make sure that the fasteners are the correct size and type for the driver.

- Check the driver head: Make sure that the driver head is clean and free of debris.

- Check the driver mechanism: If the driver is not driving the fasteners properly, there may be a problem with the driver mechanism. You may need to contact a qualified technician to service the driver.

6. What are the different types of corrugated fastener driving machines and when should each type be used?

Different types of Corrugated Fastener Driving Machines

- Manual corrugated fastener driving machines: Manual corrugated fastener driving machines are operated by hand.

- Pneumatic corrugated fastener driving machines: Pneumatic corrugated fastener driving machines are powered by compressed air.

- Electric corrugated fastener driving machines: Electric corrugated fastener driving machines are powered by electricity.

When to use each type of machine

- Manual corrugated fastener driving machines: Manual corrugated fastener driving machines are best suited for small-volume applications.

- Pneumatic corrugated fastener driving machines: Pneumatic corrugated fastener driving machines are best suited for medium-volume applications.

- Electric corrugated fastener driving machines: Electric corrugated fastener driving machines are best suited for high-volume applications.

7. How do you maintain a corrugated fastener driving machine?

- Clean the machine regularly: Remove any dust, dirt, or debris from the machine.

- Lubricate the machine regularly: Apply a light coat of lubricant to the moving parts of the machine.

- Inspect the machine regularly: Check the machine for any signs of damage or wear.

- Have the machine serviced regularly: Have the machine serviced by a qualified technician on a regular basis.

8. What are the different types of corrugated fastener driving techniques?

- Butt joint: A butt joint is made by joining two pieces of cardboard together end-to-end.

- Overlapping joint: An overlapping joint is made by overlapping two pieces of cardboard.

- L-joint: An L-joint is made by joining two pieces of cardboard at a right angle.

- T-joint: A T-joint is made by joining three pieces of cardboard together to form a T-shape.

9. What are the different types of corrugated fastener patterns?

- Regular pattern: A regular pattern is made by driving fasteners at regular intervals.

- Staggered pattern: A staggered pattern is made by driving fasteners in a staggered pattern.

- Cross pattern: A cross pattern is made by driving fasteners in a cross pattern.

10. What are the different types of corrugated fastener heads?

- Flat head: A flat head is flush with the surface of the cardboard.

- Countersunk head: A countersunk head is recessed below the surface of the cardboard.

- Oval head: An oval head is rounded and slightly raised above the surface of the cardboard.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Corrugated Fastener Driver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Corrugated Fastener Driver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Corrugated Fastener Driver is responsible for operating and maintaining a corrugated fastener machine, used to produce corrugated cardboard boxes. Key responsibilities include:

1. Machine Operation

Loading and feeding various grades of corrugated cardboard into the machine

- Adjusting machine settings and speed to optimize production

- Monitoring machine performance and identifying potential issues

2. Quality Control

Inspecting finished boxes for quality and compliance with specifications

- Ensuring proper bonding of fasteners and overall box integrity

- Identifying and resolving any defects or inconsistencies

3. Maintenance and Troubleshooting

Performing routine maintenance tasks such as cleaning, lubrication and minor repairs

- Diagnosing and troubleshooting machine malfunctions

- Coordinating with maintenance personnel for major repairs or upgrades

4. Safety Procedures

Adhering to all safety protocols and guidelines related to machine operation

- Wearing appropriate personal protective equipment

- Following proper lockout/tagout procedures

Interview Tips

To ace an interview for a Corrugated Fastener Driver position, it’s crucial to prepare thoroughly. Here are some tips to help you succeed:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and specific requirements for the role

- Visit the company’s website to learn about their products, services, and culture

- Read job descriptions carefully and identify the key skills and qualifications they are seeking

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating corrugated fastener machines and any related skills

- Quantify your accomplishments with specific metrics, such as production rates or quality improvements

- Showcase your ability to troubleshoot and resolve machine issues effectively

3. Demonstrate Safety Awareness

Stress your adherence to safety protocols and your understanding of industry-standard practices

- Discuss your knowledge of lockout/tagout procedures and proper use of personal protective equipment

- Share any relevant safety training or certifications you possess

4. Prepare for Common Interview Questions

Anticipate questions related to your experience, skills, and motivation for the role

- Practice answering questions about your ability to meet production targets

- Prepare examples of how you have handled machine malfunctions or production issues in the past

5. Dress Professionally and Arrive Punctually

Make a positive impression by dressing appropriately and arriving on time for your interview

- Choose business attire that is clean, pressed, and comfortable

- Plan your transportation and leave ample time to locate the interview venue

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Corrugated Fastener Driver interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.