Are you gearing up for a career in Heading Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Heading Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

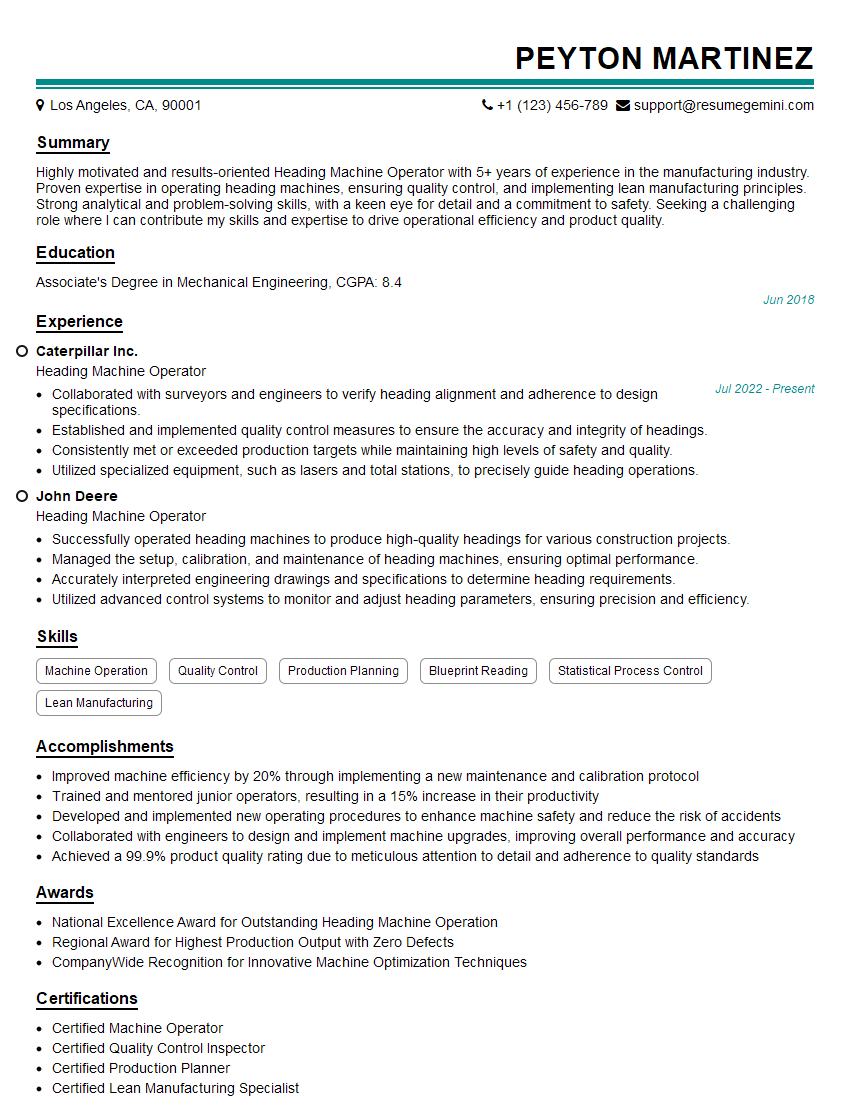

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Heading Machine Operator

1. What are the key responsibilities of a Heading Machine Operator?

As a Heading Machine Operator, my key responsibilities include:

- Operating and maintaining heading machines to produce high-quality headed parts.

- Setting up and adjusting machines according to specifications and blueprints.

- Monitoring production processes to ensure adherence to quality standards.

- Performing routine maintenance and troubleshooting to keep machines running efficiently.

- Ensuring a safe and clean work environment.

2. Describe the different types of heading machines you have experience with.

Cold Heading Machines

- High-speed cold heading machines

- Multi-station progressive heading machines

- Thread rolling machines

Warm Heading Machines

- Induction heating machines

- Gas heating machines

- Electrical resistance heating machines

3. What are the critical quality control parameters for headed parts?

The critical quality control parameters for headed parts include:

- Head diameter and height

- Shoulder diameter and length

- Knurl diameter and pitch

- Material hardness

- Surface finish

- Dimensional tolerances

4. How do you ensure that the heading machines are calibrated and maintained properly?

I follow a comprehensive maintenance schedule that includes:

- Regularly inspecting and cleaning the machines.

- Lubricating moving parts.

- Calibrating sensors and gauges.

- Performing preventive maintenance tasks.

- Troubleshooting and repairing any issues.

5. What are the common problems that you encounter when operating heading machines?

Some common problems that I encounter include:

- Machine jams due to improper feeding or tooling.

- Tool wear and breakage.

- Material defects.

- Sensor malfunctions.

- Hydraulic or electrical issues.

6. How do you troubleshoot and resolve these problems?

When troubleshooting and resolving problems, I follow these steps:

- Identify the symptoms of the problem.

- Check the machine settings and parameters.

- Inspect the tooling and material.

- Run diagnostic tests.

- Consult with maintenance personnel or technical manuals.

- Implement corrective measures.

7. What are the safety precautions that you take when operating heading machines?

I prioritize safety by:

- Wearing appropriate personal protective equipment (PPE).

- Following lockout/tagout procedures.

- Keeping the work area clean and organized.

- Being aware of the potential hazards associated with the machines.

- Reporting any unsafe conditions or practices.

8. How do you optimize the production process to maximize efficiency?

To optimize the production process, I focus on:

- Selecting the appropriate tooling and materials.

- Fine-tuning machine settings and parameters.

- Minimizing downtime by performing preventive maintenance.

- Implementing lean manufacturing techniques.

- Working closely with other team members.

9. What are the recent advancements in heading machine technology?

The heading machine industry is continuously evolving, with new advancements emerging regularly. Some recent trends include:

- Increased automation and integration with other manufacturing systems.

- Improved tool materials and coatings for extended lifespan.

- Sensor-based monitoring and control systems for enhanced precision.

- Advanced data analytics for predictive maintenance and process optimization.

10. What are your strengths and weaknesses as a Heading Machine Operator?

Strengths

- Proficient in operating and maintaining various heading machines.

- Strong understanding of quality control parameters and inspection techniques.

- Excellent troubleshooting and problem-solving skills.

- Committed to safety and maintaining a clean work environment.

Weaknesses

- Limited experience with certain specialized heading machines.

- Still developing my knowledge of advanced data analytics for process optimization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Heading Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Heading Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Heading Machine Operators are responsible for operating and maintaining heading machines, which are used to shape metal rods or wires into specific shapes. Their key responsibilities include:

1. Machine Operation

Operating heading machines to shape metal rods or wires according to specifications.

- Loading and unloading raw materials

- Setting up and adjusting machine parameters

- Monitoring machine operation

2. Machine Maintenance

Performing routine maintenance and repairs on heading machines.

- Cleaning and lubricating machines

- Replacing worn parts

- Troubleshooting and resolving technical issues

3. Product Quality

Ensuring the quality of headed products.

- Inspecting finished products

- Making adjustments to machine settings

- Maintaining records of product quality

4. Safety and Compliance

Following safety protocols and adhering to industry regulations.

- Wearing appropriate safety gear

- Understanding and following safety procedures

- Maintaining a clean and organized work environment

Interview Tips

To ace an interview for a Heading Machine Operator position, it is essential to prepare thoroughly and present yourself professionally. Here are some interview tips and hacks that can help you succeed:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific Heading Machine Operator position. This will help you understand the company’s culture, values, and the specific requirements of the role. You can visit the company’s website, read industry news, and connect with current or former employees on LinkedIn.

2. Practice Your Answers

Once you have a good understanding of the company and position, start practicing your answers to common interview questions. Think about your experiences, skills, and qualifications that are relevant to the role. You can also prepare specific examples to demonstrate your abilities. Practicing your answers will help you feel more confident and articulate during the interview.

3. Dress Professionally

The way you dress for an interview is crucial. First impressions matter, so make sure you dress professionally and appropriately. For a Heading Machine Operator position, it is recommended to wear clean and pressed work clothes, such as a button-down shirt, slacks, and closed-toe shoes.

4. Be On Time

Punctuality is a sign of respect and professionalism. Plan your journey to the interview location in advance and leave yourself plenty of time to arrive on time. If you encounter any unexpected delays, be sure to inform the interviewer as soon as possible.

5. Be Enthusiastic and Positive

Throughout the interview, maintain a positive and enthusiastic attitude. Hiring managers are looking for candidates who are genuinely interested in the position and excited about the opportunity. Show your enthusiasm by asking thoughtful questions, expressing your interest in the company, and highlighting your passion for operating heading machines.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Heading Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Heading Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.