Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Molder Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

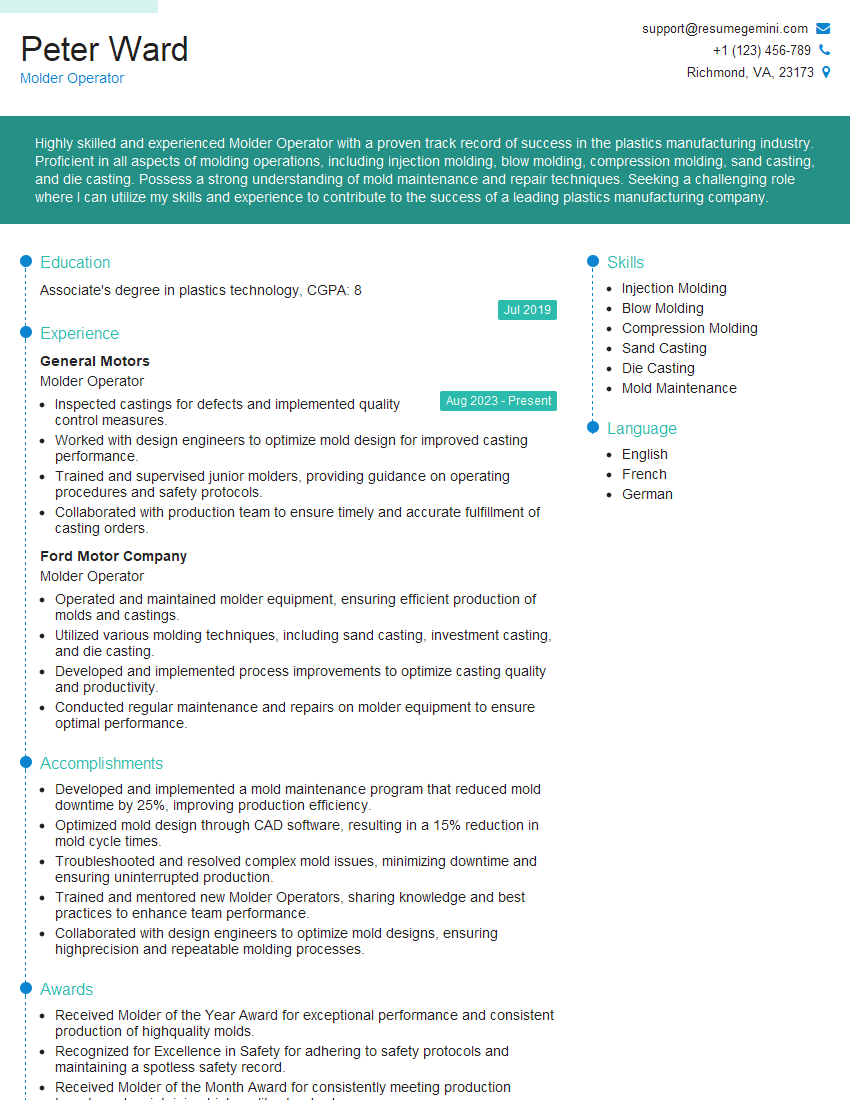

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Molder Operator

1. What are the key responsibilities of a Molder Operator?

- Operate and monitor molding machines to produce plastic or rubber products.

- Set up and adjust machines according to product specifications.

- Monitor product quality and make adjustments as needed.

- Perform routine maintenance on machines.

- Follow safety protocols and procedures.

2. Describe the different types of molding machines you have experience with?

Injection molding machines

- Used to produce a wide variety of plastic parts.

- Involves injecting molten plastic into a mold cavity.

Compression molding machines

- Used to produce rubber and plastic parts.

- Involves pressing a heated mold onto a rubber or plastic material.

Transfer molding machines

- Used to produce rubber and plastic parts.

- Involves transferring molten material from a pot to a mold cavity.

3. How do you maintain mold temperature during the molding process?

- Use temperature controllers to regulate the temperature of the mold.

- Monitor mold temperature using thermocouples or other temperature sensors.

- Adjust the flow of coolant or heating medium through the mold.

- Perform regular maintenance on the molding machine’s temperature control system.

4. How do you troubleshoot common molding defects?

- Identify the type of defect (e.g., flash, sink, knit lines).

- Determine the cause of the defect (e.g., incorrect machine settings, mold damage).

- Make adjustments to the machine or mold to correct the defect.

- Monitor the process to ensure that the defect has been resolved.

5. What are the safety precautions you take when operating a molding machine?

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and earplugs.

- Follow lockout/tagout procedures when performing maintenance on the machine.

- Be aware of the location of emergency stop buttons and other safety features.

- Never reach into the mold area while the machine is running.

- Keep the work area clean and free of debris.

6. How do you ensure the quality of molded products?

- Perform regular inspections of the molds and products.

- Use measuring tools and gauges to verify product dimensions and tolerances.

- Monitor the process parameters such as temperature, pressure, and cycle time.

- Review quality control reports and make adjustments as needed.

- Work closely with the quality control department to ensure that products meet customer specifications.

7. What are the different types of molds used in molding processes?

- Single cavity molds: Produce one part at a time.

- Multi-cavity molds: Produce multiple parts at a time.

- Family molds: Produce a variety of parts from a single mold.

- Insert molds: Used to mold inserts into parts.

- Overmold molds: Used to mold one material over another.

8. How do you calculate the cycle time for a molding machine?

- Determine the time required for each step of the cycle (e.g., filling, holding, cooling, ejection).

- Add up the times for each step to get the total cycle time.

- Consider factors such as machine speed, mold temperature, and material properties.

- Use cycle time data to optimize the molding process and increase productivity.

9. What are the different types of materials used in molding processes?

- Thermoplastics: Can be melted and reshaped multiple times.

- Thermosets: Can be melted and shaped only once.

- Elastomers: Have rubber-like properties.

- Metals: Can be cast or molded into various shapes.

- Composites: Made from a combination of materials.

10. What are the advantages and disadvantages of using robots in molding processes?

Advantages

- Increased productivity and efficiency.

- Improved product quality and consistency.

- Reduced labor costs.

- Safer work environment.

Disadvantages

- High initial investment cost.

- Requires skilled technicians for programming and maintenance.

- May not be suitable for all molding processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Molder Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Molder Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Molder Operators play a crucial role in manufacturing processes, and their key responsibilities include:

1. Mold Operation and Maintenance

Operate and maintain molding machines, ensuring they run smoothly and efficiently.

- Set up and adjust molds according to specifications.

- Monitor mold temperature, pressure, and other parameters to ensure optimal conditions.

2. Material Handling

Handle and prepare materials for molding, ensuring proper mixing and consistency.

- Weigh and measure materials according to established procedures.

- Mix and blend materials to achieve desired properties.

3. Production Monitoring and Quality Control

Monitor production processes and inspect molded parts for defects, ensuring product quality.

- Observe molding processes for any deviations from standard parameters.

- Inspect molded parts for dimensional accuracy, surface finish, and other quality aspects.

4. Safety and Maintenance

Follow safety regulations and maintain a clean and organized work environment.

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Maintain molding machines and work area to ensure optimal performance and safety.

Interview Tips

To ace the interview for a Molder Operator position, consider the following tips:

1. Research the Company and Industry

Show that you have taken the time to understand the company’s operations, products, and industry trends.

- Visit the company’s website to learn about their history, mission, and values.

- Research the industry to identify key players, trends, and technological advancements.

2. Highlight Relevant Skills and Experience

Emphasize the skills and experience that align with the job requirements. Quantify your accomplishments whenever possible.

- Discuss your experience in operating molding machines, handling materials, and conducting quality control.

- Provide specific examples of how you have improved processes, maintained equipment, or resolved production issues.

3. Demonstrate Safety Awareness

Safety is paramount in a manufacturing environment. Showcase your commitment to following safety regulations and maintaining a safe work environment.

- Explain your understanding of the company’s safety policies and procedures.

- Share examples of how you have identified and mitigated safety hazards in previous roles.

4. Prepare Questions

Asking thoughtful questions shows that you are engaged and interested in the position. Prepare questions that focus on the role, the company, and the industry.

- Inquire about specific production processes or challenges related to the role.

- Ask about the company’s growth plans or industry outlook.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Molder Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Molder Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.