Feeling lost in a sea of interview questions? Landed that dream interview for Plugging Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Plugging Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

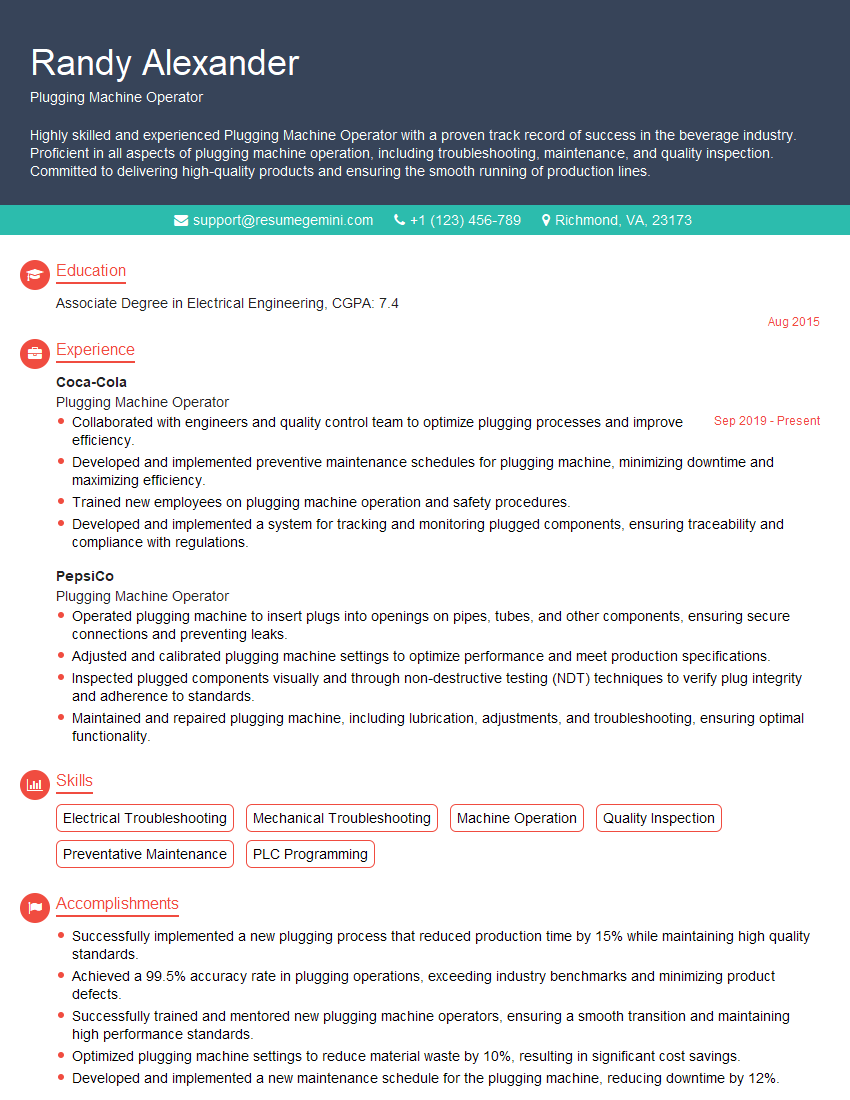

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plugging Machine Operator

1. Explain the key steps involved in operating a plugging machine?

- Setting up the machine by installing the correct plugs and adjusting the settings.

- Loading the product into the machine and starting the plugging process.

- Monitoring the machine during operation and making any necessary adjustments.

- Unloading the plugged product and inspecting it for quality.

- Performing routine maintenance and cleaning of the machine to ensure optimal performance.

2. Describe the different types of plugs and how to select the right one for a specific application?

- Rubber plugs: Used for sealing holes and preventing leaks in a variety of materials, including metal, plastic, and wood.

- Plastic plugs: Similar to rubber plugs, but offer greater durability and resistance to chemicals and solvents.

- Metal plugs: Used for heavy-duty applications, such as sealing pipes and valves, and can withstand high temperatures and pressures.

- Fiber plugs: Made from natural or synthetic fibers and used for sealing irregular-shaped holes or absorbing liquids.

- Selection of the right plug depends on factors such as the material being plugged, the size and shape of the hole, and the desired level of sealing.

3. What are the common troubleshooting techniques for resolving machine malfunctions?

- Checking for loose connections or damaged wires: Tighten connections and replace damaged wires as needed.

- Inspecting the plugs and plug feed system: Ensure that the plugs are properly installed and that the feed system is functioning correctly.

- Verifying the machine settings: Confirm that the settings are aligned with the desired plugging operation.

- Lubricating moving parts: Apply lubricant to prevent friction and wear.

- Resetting the machine: If all else fails, reset the machine to its default settings.

4. How do you ensure the quality and consistency of the plugging process?

- Regularly inspecting the machine: Checking for any wear or damage that could affect performance.

- Calibrating the machine: Ensuring that the machine is operating within specified tolerances.

- Using high-quality plugs: Selecting plugs that meet industry standards and are appropriate for the application.

- Following established operating procedures: Adhering to standard procedures to ensure consistency.

- Performing regular quality checks: Inspecting plugged products to verify their quality and meet customer specifications.

5. What safety precautions should be taken when operating a plugging machine?

- Wearing appropriate safety gear: Including safety glasses, gloves, and ear protection.

- Keeping the work area clean and organized: Preventing tripping hazards and ensuring a safe working environment.

- Being aware of moving parts: Avoiding contact with machinery that could cause injury.

- Following lockout/tagout procedures: When performing maintenance or repairs to prevent accidental startup.

- Reporting any safety concerns: Notifying supervisors or safety personnel of any potential hazards.

6. How do you prioritize tasks and manage your time effectively when working in a high-volume production environment?

- Understanding production goals and deadlines: Being aware of the targets and time constraints.

- Prioritizing tasks based on urgency and importance: Focusing on completing critical tasks first.

- Breaking down large tasks into smaller, manageable steps: Making them less overwhelming and easier to complete.

- Utilizing time management techniques: Such as the Pomodoro Technique or Eisenhower Matrix, to maximize productivity.

- Delegating tasks when possible: Assigning responsibilities to others to free up time for more important matters.

7. What is your understanding of the industry standards and regulations related to plugging machine operation?

- OSHA regulations for workplace safety, including machine guarding and electrical safety.

- ANSI standards for plugging equipment and materials, ensuring quality and reliability.

- ISO standards for quality management systems, promoting consistency and efficiency in production.

- ASTM standards for testing and evaluating plugs and plugging materials.

- Understanding these standards helps ensure compliance, safety, and the production of high-quality plugged products.

8. How do you stay up to date with advancements and best practices in plugging machine operation?

- Attending industry conferences and workshops: Networking with professionals and learning about latest technologies.

- Reading trade publications and technical journals: Staying informed about industry trends and advancements.

- Consulting with equipment manufacturers and suppliers: Seeking guidance and support on best practices.

- Participating in online forums and discussion groups: Exchanging knowledge and insights with other plugging machine operators.

- Seeking feedback from supervisors and colleagues: Continuously improving skills and staying aligned with company policies.

9. How do you measure the performance and efficiency of a plugging machine?

- Tracking production output: Monitoring the number of products plugged per hour or shift.

- Measuring accuracy and quality: Ensuring that plugs are inserted correctly and meet specifications.

- Evaluating machine uptime: Minimizing downtime and maximizing production efficiency.

- Analyzing energy consumption: Identifying areas for improvement and reducing operating costs.

- Using performance metrics and data analysis: To optimize machine performance and identify areas for improvement.

10. How do you handle unexpected challenges or equipment malfunctions during production?

- Assess the situation and identify the cause: Determining the root of the problem to find the best solution.

- Consult with supervisors or technical support: Seeking guidance and expertise when needed.

- Troubleshoot and implement solutions: Using technical knowledge and problem-solving skills to resolve the issue.

- Prioritize safety: Ensuring that all necessary safety precautions are taken before attempting any repairs.

- Document the issue and resolution: Maintaining a record for future reference and to prevent reoccurrence.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plugging Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plugging Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Plugging Machine Operator is responsible for operating and maintaining plugging machines, which are used to seal and protect pipelines from leaks. The primary tasks of a Plugging Machine Operator include:

1. Machine Operation

Operating plugging machines to insert plugs into pipelines, ensuring proper sealing and protection against leaks.

- Setting up and calibrating plugging machines according to specifications.

- Loading and unloading plugs into the machine.

- Monitoring machine performance and making necessary adjustments.

2. Maintenance and Inspection

Performing routine maintenance and inspections of plugging machines to keep them in optimal working condition.

- Lubricating and cleaning machine components.

- Checking for any wear or damage.

- Reporting any issues or repairs to supervisors.

3. Quality Control

Ensuring the quality of plugging operations by following established procedures and industry standards.

- Inspecting plugs for defects or damage.

- Verifying the proper sealing of plugs.

- Maintaining records of plugging operations.

4. Safety and Compliance

Adhering to all safety regulations and company policies while operating plugging machines.

- Wearing appropriate personal protective equipment.

- Following lockout/tagout procedures.

- Reporting any safety hazards or incidents.

Interview Tips

To ace an interview for a Plugging Machine Operator position, candidates should focus on highlighting their technical skills, attention to detail, and safety consciousness.

1. Technical Expertise

Emphasize your proficiency in operating and maintaining plugging machines. Discuss your experience with different types of machines, their capabilities, and any troubleshooting or repair skills you possess.

- Example: “I have extensive experience operating both hydraulic and pneumatic plugging machines, including the latest models from leading manufacturers.”

- Example: “I am highly skilled in calibrating machines, loading and unloading plugs, and monitoring machine performance to ensure optimal operation.”

2. Attention to Detail

Highlight your meticulous nature and ability to follow procedures precisely. Explain how you ensure the quality of your work, inspect plugs thoroughly, and maintain accurate records.

- Example: “I am highly detail-oriented and always strive for accuracy in all aspects of my work. I meticulously inspect every plug before and after insertion to ensure proper sealing.”

- Example: “I maintain comprehensive records of all plugging operations, including details of plugs used, machine settings, and any observations or issues encountered.”

3. Safety and Compliance

Demonstrate your commitment to safety and compliance. Describe your understanding of industry regulations and company policies.

- Example: “I am fully aware of all safety regulations and procedures related to plugging machine operation, including lockout/tagout and proper use of personal protective equipment.”

- Example: “I have a proven track record of operating plugging machines in a safe and compliant manner, with no accidents or incidents on my record.”

4. Communication and Teamwork

Explain your ability to communicate effectively with colleagues, supervisors, and clients. Discuss any experience working as part of a team and contributing to a shared goal.

- Example: “I am a strong communicator with excellent interpersonal skills. I can clearly explain technical information to non-technical stakeholders and effectively collaborate with team members to achieve project goals.”

- Example: “I have experience working as part of a team to ensure the smooth and efficient operation of a plugging machine crew, contributing to the successful completion of numerous pipeline projects.”

5. Industry Knowledge and Trends

Show that you are up-to-date on industry trends and advancements. Discuss any relevant courses, certifications, or research you have undertaken to stay current.

- Example: “I regularly attend industry conferences and workshops to stay informed about the latest technological advancements and best practices in plugging machine operation.”

- Example: “I am pursuing a certification in advanced plugging techniques to enhance my skills and knowledge in this field.”

6. Problem-Solving and Critical Thinking

Explain how you approach problem-solving and critical thinking in your work. Provide examples of situations where you identified and resolved issues.

- Example: “I am a quick-thinking problem-solver with a strong ability to analyze situations and develop effective solutions.”

- Example: “In a previous role, I encountered a problem with a faulty plugging machine that was causing delays. I systematically diagnosed the issue, identified the root cause, and implemented a repair that resolved the problem and minimized downtime.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Plugging Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.