Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Whiting Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

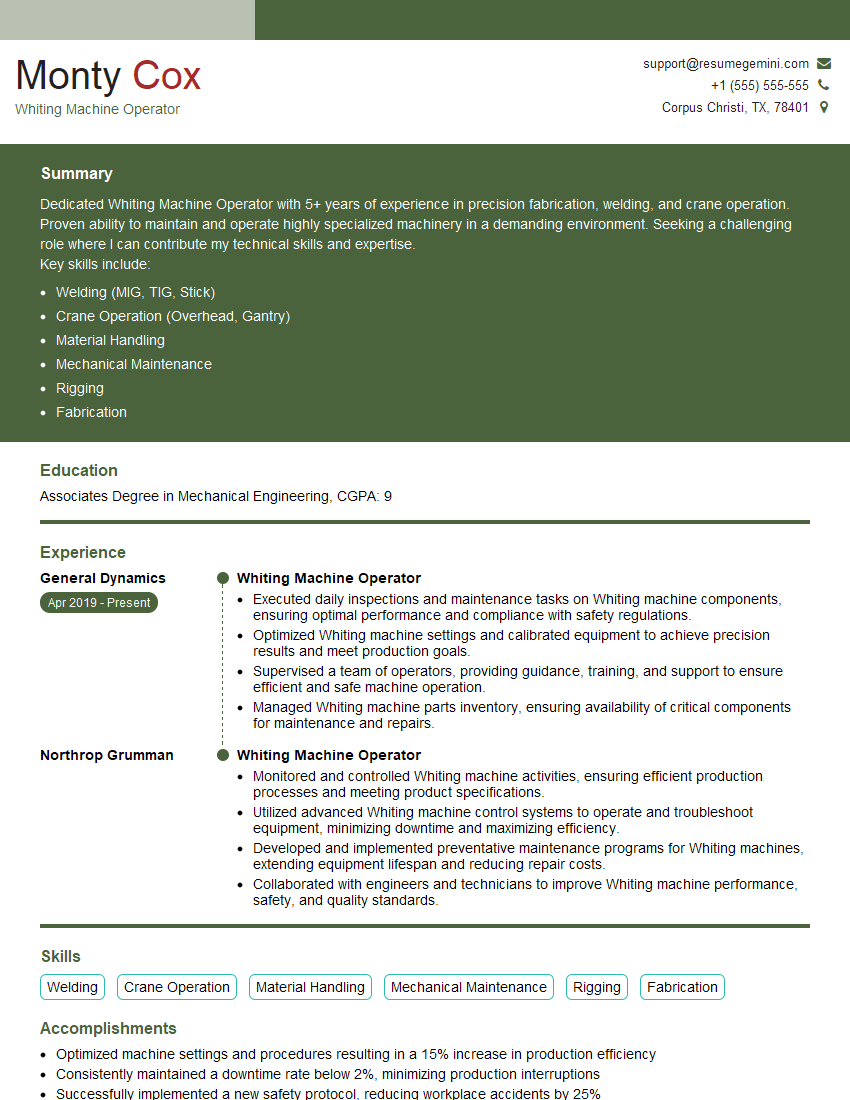

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Whiting Machine Operator

1. How do you ensure the accuracy and consistency of the cutting process on a Whiting machine?

To ensure accuracy and consistency in the cutting process using a Whiting machine, I follow the below steps:

- Regular calibration: I perform regular calibration checks to ensure the machine’s precision and accuracy.

- Blade maintenance: I ensure that the blades are sharp and properly aligned to achieve clean and precise cuts.

2. How do you troubleshoot common problems encountered on a Whiting machine?

Mechanical issues

- Motor overheating: I check for any blockages or excessive friction in the moving parts and take necessary corrective actions.

- Hydraulic system failures: I inspect for leaks or contamination in the hydraulic system and ensure proper fluid levels and pressure.

Electrical issues

- Electrical shorts: I use a multimeter to locate and repair any electrical shorts or loose connections.

- Power supply problems: I verify the power supply to the machine and ensure proper voltage and amperage.

3. Describe the safety precautions you observe when operating a Whiting machine.

Safety is my top priority when operating a Whiting machine. I adhere to the following precautions:

- Protective gear: I wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Machine guarding: I ensure that all machine guards are in place and operational to prevent contact with moving parts.

- Lockout/Tagout procedures: I follow established lockout/tagout procedures before performing any maintenance or repairs.

4. Explain the maintenance procedures you perform on a Whiting machine to ensure optimal performance.

To maintain optimal performance of the Whiting machine, I conduct the following maintenance tasks:

- Daily inspections: I inspect the machine for any signs of wear or damage and ensure lubrication.

- Regular cleaning: I clean the machine to remove debris and prevent buildup that could affect performance.

- Scheduled maintenance: I follow the manufacturer’s recommended maintenance schedule for servicing and replacing components.

5. How do you optimize the cutting parameters on a Whiting machine to achieve desired results?

To optimize cutting parameters on a Whiting machine, I consider the following factors:

- Material properties: I adjust the cutting speed, feed rate, and depth of cut based on the material being cut.

- Machine capabilities: I ensure that the machine is set up to handle the required cutting parameters.

- Desired surface finish: I adjust the cutting parameters to achieve the desired surface finish on the workpiece.

6. Describe the steps involved in loading and unloading workpieces on a Whiting machine.

To load and unload workpieces on a Whiting machine, I follow these steps:

- Loading: I ensure the machine table is clean and free of debris. I then position the workpiece securely on the table and clamp it in place.

- Unloading: Once the cutting process is complete, I release the clamps and carefully remove the workpiece from the table.

7. What is your approach to solving complex cutting problems on a Whiting machine?

When facing complex cutting problems on a Whiting machine, I follow a structured approach:

- Analysis: I analyze the problem to identify the root cause, considering factors like material properties, cutting parameters, and machine settings.

- Troubleshooting: I troubleshoot the machine and its components to isolate the issue and implement corrective actions.

- Optimization: I optimize the cutting parameters and machine settings to achieve the desired results.

8. How do you ensure the quality of cut workpieces produced on a Whiting machine?

To ensure the quality of cut workpieces, I follow these practices:

- Regular inspections: I regularly inspect the finished workpieces for any defects or deviations from specifications.

- Precision measurement: I use precision measuring tools to verify the accuracy and dimensions of the cut workpieces.

- Quality control: I adhere to established quality control procedures to prevent non-conforming workpieces from being released.

9. What do you consider to be the most challenging aspect of operating a Whiting machine?

The most challenging aspect of operating a Whiting machine is maintaining consistent accuracy and precision throughout the cutting process. Factors such as material variations, tool wear, and environmental conditions can affect the outcome, requiring constant monitoring and adjustments.

10. How do you stay up-to-date with the latest advancements in Whiting machine technology?

I stay up-to-date with the latest advancements in Whiting machine technology through the following methods:

- Industry events: Attending industry conferences and exhibitions allows me to interact with experts and learn about new technologies.

- Online resources: I regularly explore online forums, technical articles, and manufacturer websites for information on new developments.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Whiting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Whiting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Whiting Machine Operator is responsible for operating and managing Whiting Machine, a specialized piece of equipment used in the manufacturing industry. The key job responsibilities include:

1. Machine Operation

Operating and controlling Whiting Machine to manufacture or process materials

- Setting up the machine according to production requirements

- Monitoring the machine during operation and making adjustments as needed

2. Quality Control

Performing quality checks on products and ensuring they meet specifications

- Inspecting products for defects and inaccuracies

- Taking corrective actions to eliminate or minimize defects

3. Maintenance and Repair

Performing routine maintenance and repairs on Whiting Machine

- Lubricating and cleaning the machine

- Replacing worn or damaged parts

4. Safety Compliance

Complying with safety regulations and guidelines

- Wearing appropriate protective gear

- Following safety procedures

Interview Tips

Preparing for an interview for a Whiting Machine Operator position requires thorough understanding of the role and its requirements. Here are some tips for candidates to ace the interview:

1. Research and Know the Job

Research the company and the specific role you are applying for, paying close attention to the job description and responsibilities.

- Familiarize yourself with the Whiting Machine, its operation, and its applications.

- Understand the quality control processes and safety regulations relevant to the job.

2. Highlight Relevant Experience

In your resume and during the interview, emphasize your relevant skills and experience that align with the job requirements.

- Showcase your prior experience operating Whiting Machine or similar equipment.

- Highlight your quality control experience and ability to identify and correct defects.

3. Demonstrate Safety Awareness

Emphasize your understanding and adherence to safety regulations in your work.

- Explain your experience in following safety guidelines and using personal protective equipment.

- Discuss any safety certifications you hold or are pursuing.

4. Practice and Prepare Common Interview Questions

Anticipate and prepare answers to common interview questions related to the role.

- Practice describing your experience operating Whiting Machine or similar equipment.

- Prepare examples of how you have handled quality control issues in previous roles.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Whiting Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!