Feeling lost in a sea of interview questions? Landed that dream interview for Wood Milling Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Wood Milling Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

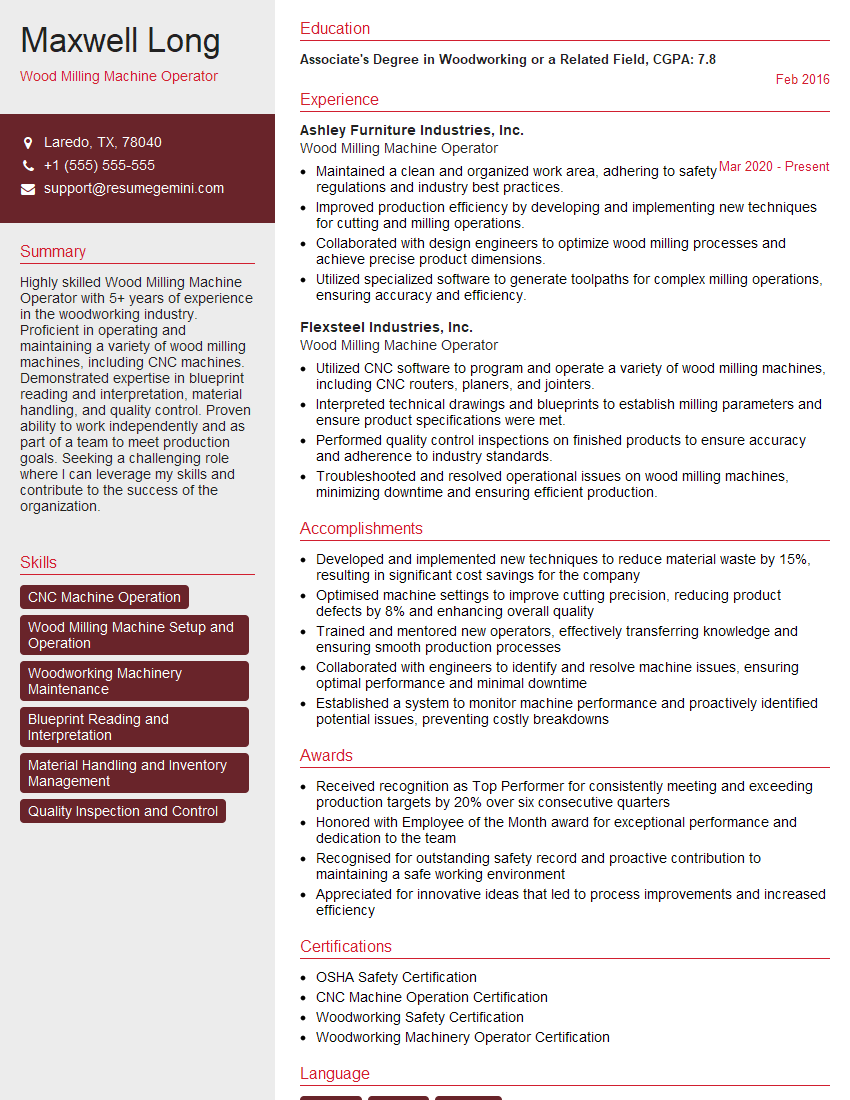

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Milling Machine Operator

1. What are the different types of wood milling machines?

There are three main types of wood milling machines: horizontal, vertical, and universal. Horizontal milling machines have the spindle mounted horizontally, while vertical milling machines have the spindle mounted vertically. Universal milling machines can be used for both horizontal and vertical milling.

2. What are the different types of wood milling cutters?

End mills

- Used for cutting slots, pockets, and other shapes in wood.

- Come in a variety of sizes and shapes.

Router bits

- Used for cutting decorative edges, profiles, and other shapes in wood.

- Come in a variety of sizes and shapes.

Saw blades

- Used for cutting straight lines and curves in wood.

- Come in a variety of sizes and tooth configurations.

3. What are the safety precautions that must be taken when operating a wood milling machine?

There are a number of safety precautions that must be taken when operating a wood milling machine, including:

- Always wear appropriate safety gear, including eye protection, hearing protection, and gloves.

- Never operate the machine if you are not properly trained.

- Inspect the machine before each use to make sure that it is in good working order.

- Make sure that the workpiece is securely clamped to the table before starting the machine.

- Never reach over the cutting head while the machine is running.

- Always use sharp cutters and keep the machine clean.

4. What are the different types of wood milling operations?

There are a variety of different wood milling operations, including:

- Sawing

- Routing

- Shaping

- Planing

- Jointing

- Moulding

5. What are the different types of wood milling machines?

- Horizontal milling machines

- Vertical milling machines

- Universal milling machines

6. What are the different types of wood milling cutters?

- End mills

- Router bits

- Saw blades

7. What are the safety precautions that must be taken when operating a wood milling machine?

- Wear appropriate safety gear

- Never operate the machine if you are not properly trained

- Inspect the machine before each use

- Make sure that the workpiece is securely clamped to the table before starting the machine

- Never reach over the cutting head while the machine is running

- Always use sharp cutters and keep the machine clean

8. What are the different types of wood milling operations?

- Sawing

- Routing

- Shaping

- Planing

- Jointing

- Moulding

9. What are the different types of wood milling machines?

- Horizontal milling machines

- Vertical milling machines

- Universal milling machines

10. What are the different types of wood milling cutters?

- End mills

- Router bits

- Saw blades

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Milling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Milling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wood Milling Machine Operators play a crucial role in producing high-quality wood products. Key responsibilities include:

1. Machine Operation

- Set up and operate wood milling machines, ensuring proper tool selection and machine settings.

- Adjust feed rates, speeds, and cutting depths to achieve precise results.

2. Material Handling

- Inspect raw materials for defects and determine suitable cutting techniques.

- Securely load and unload wood pieces onto the machine and remove finished products.

3. Quality Control

- Monitor the milling process, ensuring that products meet specifications and quality standards.

- Inspect finished products for defects and make necessary adjustments to the machine or cutting process.

4. Maintenance and Troubleshooting

- Perform routine maintenance and cleaning on the milling machine.

- Identify and resolve any technical issues to minimize downtime and ensure machine efficiency.

Interview Tips

To ace the interview for a Wood Milling Machine Operator position, candidates should consider the following preparation tips:

1. Research the Company and Industry

- Thoroughly research the company you’re applying to, including their products, services, and industry position.

- Stay updated on current industry trends and advancements in wood milling technology.

2. Highlight Relevant Skills and Experience

- Showcase your proficiency in operating wood milling machines, including experience with various types of tools and equipment.

- Emphasize your attention to detail, problem-solving abilities, and commitment to quality.

3. Prepare for Technical Questions

- Expect questions related to machine setup, cutting techniques, and quality control procedures.

- Practice answering questions about troubleshooting common machine issues and identifying defects in wood products.

4. Communicate Safety Practices

- Demonstrate a strong understanding of workplace safety protocols for wood milling operations.

- Discuss your experience in using personal protective equipment and following safety guidelines.

5. Ask Thoughtful Questions

- Prepare intelligent questions that indicate your interest in the role and the company.

- Ask about the training and development opportunities provided for the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wood Milling Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!