Are you gearing up for a career in Veneer Marker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Veneer Marker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

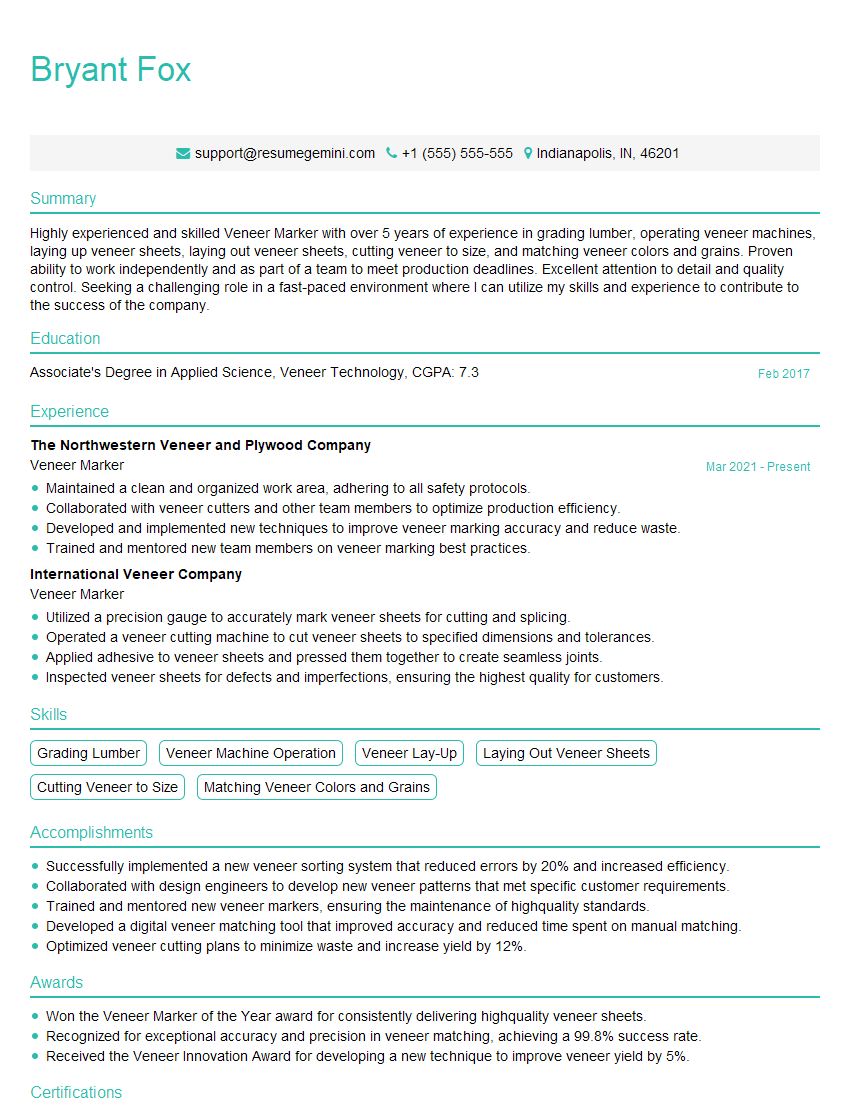

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Veneer Marker

1. What are the main factors to consider when selecting veneer for a particular project?

When selecting veneer for a project, crucial factors to consider include:

- Project Design: Matching the veneer species and grain pattern to the overall design aesthetic.

- Durability Requirements: Considering the expected wear and tear on the veneer surface.

- Substrate Compatibility: Ensuring the veneer is compatible with the underlying substrate.

- Cost Considerations: Balancing the quality and cost of the veneer relative to the project budget.

- Availability: Verifying that the desired veneer species is readily available.

2. How do you determine the proper thickness of veneer for a given application?

Thickness Considerations:

- Substrate Thickness: Matching veneer thickness to the substrate to avoid warping or buckling.

- Application Type: Veneer thickness varies depending on the intended use, such as furniture, architectural panels, or musical instruments.

- Desired Flexibility: Thinner veneers are more flexible, while thicker veneers provide greater strength and stability.

Formula:

Additionally, the formula Thickness = (Knife Setting + 0.005) can be used to calculate the final veneer thickness based on the knife setting.

3. What techniques do you use to match the grain pattern and color of veneer pieces for a seamless appearance?

Matching grain patterns and colors requires the following techniques:

- Manual Matching: Examining individual veneer sheets and manually selecting pieces with similar patterns and hues.

- Book Matching: Using adjacent veneers from the same log, ensuring symmetry in grain and color.

- Slip Matching: Offsetting veneer pieces slightly to create a flowing and continuous grain pattern.

- Color Toning: Applying stains or dyes to subtly adjust the color of certain veneer pieces for a more uniform look.

4. How do you handle defects or imperfections in veneers during the application process?

To effectively manage defects in veneers:

- Inspection and Sorting: Thoroughly inspecting veneers before use to identify any defects.

- Repair Techniques: Employing repair methods such as patching, filling, or inlaying to conceal minor defects.

- Design Considerations: Incorporating defects into the design as unique elements, such as inlays or decorative features.

- Customer Communication: Discussing potential defects and repair options with clients to manage expectations.

5. What is the significance of proper adhesive selection in veneer applications?

Selecting the appropriate adhesive is crucial for:

- Bond Strength: Ensuring a strong and lasting bond between the veneer and substrate.

- Adhesive Type: Choosing adhesives compatible with the specific veneer species and substrate material.

- Working Time: Considering the open time of the adhesive to allow for proper veneer alignment.

- Environmental Factors: Selecting adhesives resistant to moisture, temperature fluctuations, and UV exposure.

- Substrate Preparation: Matching adhesives to properly prepared substrates, ensuring optimal adhesion.

6. How do you prevent veneer from warping or buckling during and after application?

Preventing warping and buckling involves:

- Moisture Control: Maintaining proper moisture levels in veneers and substrates before and during application.

- Substrate Flatness: Using flat and stable substrates to prevent uneven expansion or contraction.

- Grain Direction: Matching veneer grain direction to minimize stress and reduce the risk of twisting.

- Gluing Techniques: Applying adhesive evenly and using clamps or weights to ensure proper contact and bonding.

- Post-Application Care: Allowing ample time for adhesives to cure, controlling temperature and humidity, and avoiding exposure to direct sunlight.

7. What are the different methods of veneer finishing, and when would you recommend each technique?

Finishing Techniques:

- Dyeing: Adding color and enhancing grain patterns.

- Staining: Adjusting color tones and highlighting natural features.

- Oiling: Preserving and enhancing the natural beauty of the wood.

- Lacquer: Providing a durable and high-gloss finish.

- Polyurethane: Offering protection and resistance to wear and moisture.

Recommendation:

The choice of finishing technique depends on factors such as desired aesthetic, protection requirements, and veneer species.

8. What are the quality control measures you implement to ensure the production of high-quality veneer products?

Quality control measures include:

- Raw Material Inspection: Examining veneers for defects and ensuring compliance with specifications.

- Process Monitoring: Monitoring key stages of veneer production to identify potential issues.

- Sample Testing: Conducting tests to verify veneer thickness, strength, and adhesion.

- Regular Calibrations: Calibrating equipment regularly to ensure accuracy and precision.

- Documentation: Maintaining detailed records of production processes and quality control results.

9. What are the common challenges you encounter in veneer marking, and how do you overcome them?

Challenges:

- Grain Matching: Matching grain patterns and colors between adjacent veneers.

- Defects: Dealing with natural defects in veneers, such as knots or cracks.

- Substrate Variations: Accommodating variations in substrate thickness or surface conditions.

- Time Constraints: Balancing quality with production efficiency.

Solutions:

Overcoming challenges requires skill, experience, and problem-solving abilities, such as employing manual matching techniques, repairing defects, adapting to substrate variations, and optimizing production processes.

10. How do you stay up-to-date with the latest advancements and best practices in veneer marking techniques?

To stay current with advancements and best practices:

- Industry Publications: Subscribing to trade magazines and journals.

- Conferences and Workshops: Attending industry events to learn from experts.

- Online Resources: Exploring websites and forums dedicated to veneer marking.

- Collaboration: Engaging with colleagues and sharing knowledge.

- Research and Development: Experimenting with new techniques and materials to improve productivity and quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Veneer Marker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Veneer Marker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Veneer markers play a vital role in the production of high-quality wooden products. Their expertise ensures optimum utilization of raw materials and prevents wastage. Essential responsibilities include:

1. Log Assessment and Selection

Examining incoming logs to determine their suitability for veneer production based on factors such as size, grain patterns, and defects. Selecting the most appropriate logs for maximum yield.

2. Marking Logs for Cutting

Using specialized tools and techniques to mark logs accurately, indicating the areas to be peeled for veneer. Ensuring precise markings to minimize waste and enhance veneer quality.

3. Supervising Veneer Peeling

Overseeing the veneer peeling process to ensure the production of veneers with desired thickness and quality. Monitoring equipment, adjusting settings, and troubleshooting any irregularities.

4. Veneer Inspection and Grading

Evaluating peeled veneers for defects, such as knots, splits, and discolorations. Grading veneers based on quality standards, ensuring they meet customer specifications.

5. Maintaining Equipment and Facility

Performing routine maintenance and calibration of marking tools and equipment. Maintaining a clean and organized work environment to facilitate efficient veneer production.

Interview Tips

To ace an interview for a Veneer Marker position, consider the following tips:

1. Research the Industry and Company

Familiarize yourself with the veneer industry, its processes, and the specific requirements of the company you are applying to. Understanding the industry dynamics and company culture will demonstrate your interest and commitment.

2. Highlight Relevant Experience and Skills

Emphasize your experience in log assessment, veneer cutting, inspection, or other related areas. Quantify your achievements using specific metrics to showcase your impact on veneer production.

3. Demonstrate Technical Expertise

Discuss your knowledge of veneer marking techniques, equipment calibration, and veneer grading standards. Explain how you utilize these skills to optimize veneer quality and minimize waste.

4. Prepare for Specific Interview Questions

Research common interview questions for Veneer Marker positions. Prepare thoughtful responses that highlight your skills, experience, and enthusiasm for the role. Consider questions such as:

- Can you describe your process for evaluating logs for veneer production?

- How do you ensure precision in marking logs for cutting?

- What are the key factors you consider when grading veneers?

5. Practice Answering Hypothetical Scenarios

Interviewers may present hypothetical scenarios to assess your problem-solving abilities. For example, they may ask how you would handle a situation where a log has unexpected defects or how you would optimize veneer production with limited raw materials. Be prepared to provide detailed and well-reasoned responses.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Veneer Marker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.