Feeling lost in a sea of interview questions? Landed that dream interview for Operations and Maintenance Technician (O & M Technician) but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Operations and Maintenance Technician (O & M Technician) interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

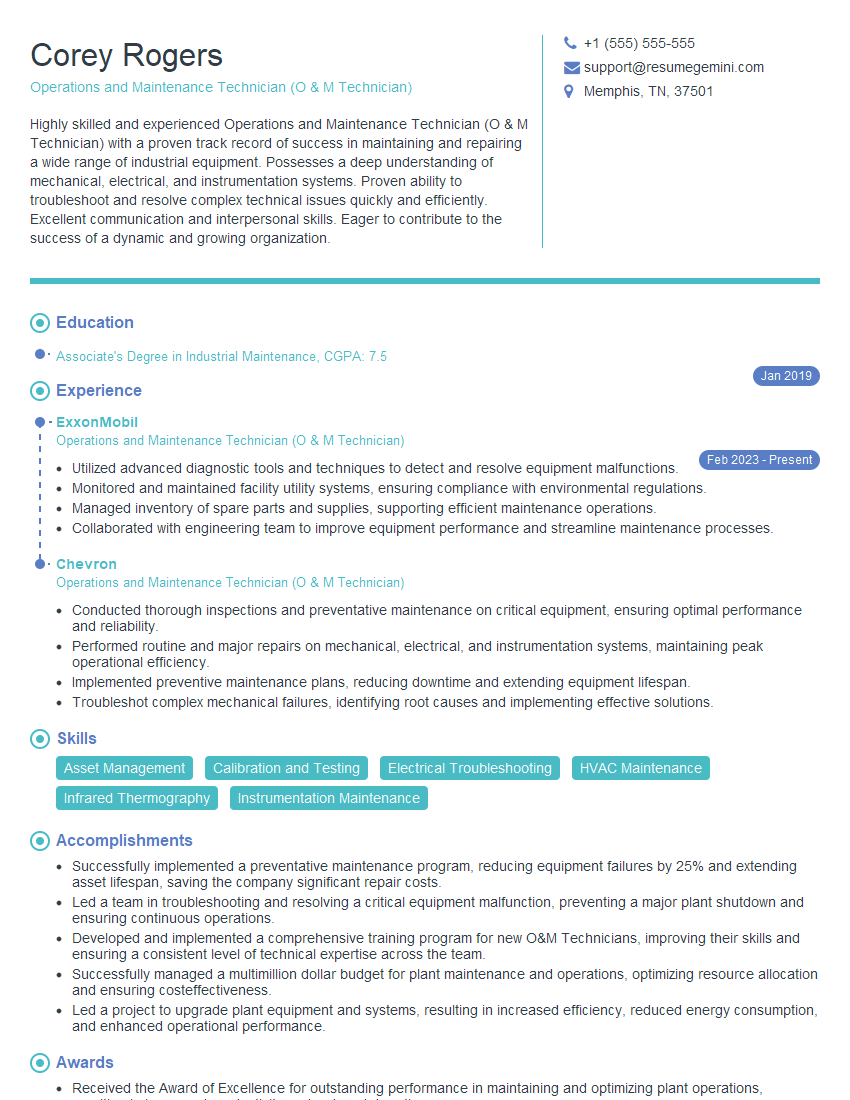

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Operations and Maintenance Technician (O & M Technician)

1. Describe your experience with troubleshooting and repairing industrial machinery?

During my tenure at ABC Company, I was responsible for troubleshooting and repairing a wide range of industrial machinery, including conveyor systems, packaging machines, and production lines. I have a strong understanding of mechanical, electrical, and hydraulic systems, which enables me to quickly identify and resolve issues.

2. How do you prioritize tasks and manage multiple projects simultaneously?

Time Management

- I use a project management tool to track tasks, deadlines, and dependencies.

- I prioritize tasks based on their importance and urgency.

Communication

- I communicate regularly with colleagues and supervisors to ensure that priorities are aligned.

- I delegate tasks effectively to ensure timely completion.

3. What preventive maintenance strategies have you implemented to reduce equipment downtime?

- Regular inspections and scheduled maintenance based on manufacturer recommendations.

- Condition monitoring using sensors and diagnostic tools to identify potential issues early.

- Root cause analysis to identify and address recurring problems.

- Training programs for operators to improve maintenance knowledge.

4. How do you stay up-to-date with advancements in maintenance technology?

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Participating in online forums and discussions.

- Seeking training and certifications in emerging technologies.

5. Describe your experience with using diagnostic equipment and software?

I have experience using a variety of diagnostic equipment and software for troubleshooting and maintenance purposes. This includes:

- Multimeters and oscilloscopes for electrical diagnostics.

- Vibration analyzers for mechanical diagnostics.

- Infrared cameras for thermal diagnostics.

- Computer-aided maintenance management systems (CMMS) for asset management and maintenance planning.

6. How do you collaborate with other departments, such as production or engineering, to ensure smooth operations?

- Regular communication and meetings to discuss maintenance needs and production schedules.

- Participation in cross-functional teams to identify and resolve operational issues.

- Providing maintenance feedback to engineering for design improvements.

7. Describe your experience with safety protocols and procedures in an industrial environment?

- Adherence to all safety regulations and guidelines.

- Regular participation in safety training and drills.

- Proactive identification and mitigation of safety hazards.

- Use of personal protective equipment (PPE).

8. How do you handle emergency situations that require immediate action?

- Prioritize safety and secure the area if necessary.

- Assess the situation and identify the root cause.

- Take immediate action to minimize damage and prevent further escalation.

- Communicate with management and other relevant parties.

9. Describe your understanding of lean manufacturing principles and how you have applied them?

- Reducing waste and inefficiencies in maintenance processes.

- Improving equipment reliability and uptime.

- Optimizing inventory levels and reducing lead times.

- Empowering operators and involving them in maintenance activities.

10. Why are you interested in this role and how do your skills and experience align with our company’s needs?

I am interested in this role because it aligns perfectly with my skills and experience as an Operations and Maintenance Technician. I have a strong understanding of industrial machinery, preventive maintenance strategies, and diagnostic equipment. I am also proficient in safety protocols and lean manufacturing principles. I am confident that I can leverage my expertise to contribute to the smooth and efficient operation of your facility.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Operations and Maintenance Technician (O & M Technician).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Operations and Maintenance Technician (O & M Technician)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Maintain and repair electrical and mechanical systems

This includes:

- Inspecting equipment for wear and damage

- Replacing worn or damaged parts

- Adjusting and calibrating equipment

- Troubleshooting and repairing electrical and mechanical problems

- Performing preventative maintenance

2. Install new equipment

This includes:

- Unpacking, assembling, and installing new equipment

- Connecting electrical and mechanical systems

- Testing and adjusting equipment

- Training personnel on new equipment

3. Supervise and train maintenance staff

This includes:

- Providing guidance and support to maintenance staff

- Training staff on new equipment and procedures

- Evaluating staff performance

- Motivating and recognizing staff

4. Manage inventory of maintenance supplies and equipment

This includes:

- Ordering, receiving, and storing maintenance supplies

- Maintaining inventory records

- Disposing of hazardous waste

Interview Tips

1. Research the company and the job

Before your interview, take some time to research the company and the job you’re applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the job. You can research the company’s website, social media pages, and news articles.

- Be prepared to talk about how your skills and experience match the requirements of the job.

- Highlight your knowledge of the company’s industry and your understanding of the company’s culture.

2. Practice answering common interview questions

There are some common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this job?”. It’s a good idea to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

- Use the STAR method to answer interview questions.

- Situation: Describe the situation you were in.

- Task: Explain the task you were responsible for.

- Action: Describe the actions you took.

- Result: Explain the results of your actions.

3. Be prepared to ask questions

Asking questions at the end of your interview shows that you’re interested in the job and the company. It’s also an opportunity for you to learn more about the company and the position. Some good questions to ask include:

- What are the biggest challenges facing the company right now?

- What are the company’s goals for the next year?

- What are the opportunities for advancement within the company?

- How would you describe the company’s culture?

4. Follow up after the interview

After the interview, send a thank-you note to the interviewer. This is a simple way to show your appreciation for their time and consideration. You can also use the thank-you note to reiterate your interest in the job and highlight any specific skills or experience that you think would be particularly valuable to the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Operations and Maintenance Technician (O & M Technician) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!