Are you gearing up for an interview for a Compressor Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Compressor Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

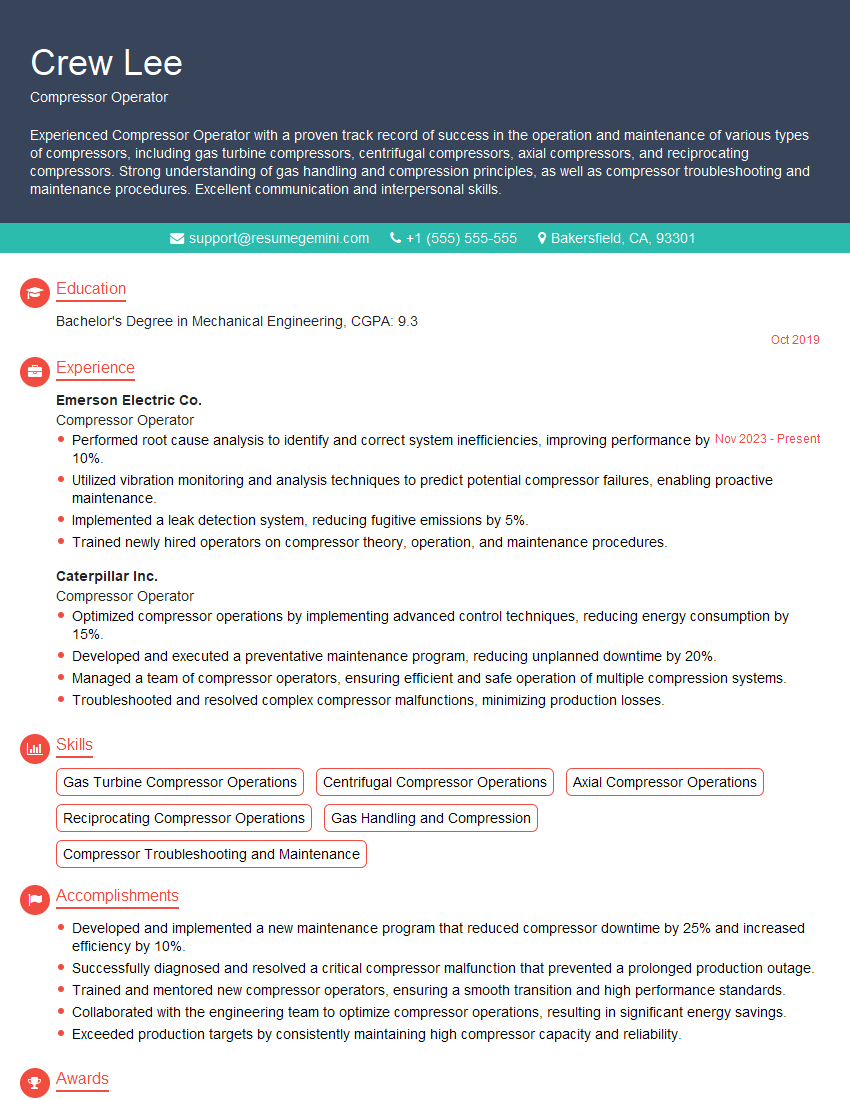

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Compressor Operator

1. Describe the types of compressors you have operated and their applications.

- Reciprocating compressors: Used for high-pressure applications such as air conditioning and refrigeration.

- Centrifugal compressors: Used for medium-pressure applications such as gas turbines and chemical processing.

- Axial compressors: Used for low-pressure applications such as jet engines and wind turbines.

- Screw compressors: Used for medium-pressure applications such as air compressors and industrial machinery.

2. Explain the process of starting and stopping a compressor safely.

Pre-Start Checks

- Verify oil level and pressure.

- Check cooling system for leaks or blockages.

- Ensure all valves are in the correct positions.

Starting

- Slowly open the suction valve.

- Start the motor and allow the compressor to reach operating speed.

- Gradually open the discharge valve.

Stopping

- Close the discharge valve.

- Close the suction valve.

- Stop the motor.

3. How do you monitor and maintain the performance of a compressor system?

- Monitoring pressure, temperature, and flow rate.

- Checking for leaks and vibration.

- Inspecting and cleaning components regularly.

- Performing scheduled maintenance as per the manufacturer’s recommendations.

4. Describe the safety precautions you take when operating a compressor.

- Wearing appropriate personal protective equipment (PPE) such as safety glasses and earplugs.

- Following lockout/tagout procedures.

- Avoiding contact with moving parts.

- Being aware of potential hazards such as high pressure and leaks.

5. What is the role of the compressor controller in the operation of a compressor system?

- Monitoring and controlling compressor speed and pressure.

- Protecting the compressor from overloads and other faults.

- Optimizing compressor efficiency and performance.

6. How do you troubleshoot common compressor problems?

- Identifying the symptoms of the problem.

- Checking for leaks, blockages, or electrical faults.

- Consulting with the manufacturer’s manual.

- Performing diagnostic tests.

7. Describe the importance of lubrication in a compressor system.

- Reducing friction and wear in moving parts.

- Preventing corrosion and seizures.

- Cooling components and dissipating heat.

8. How do you ensure that a compressor system is energy efficient?

- Selecting the right compressor for the application.

- Matching the compressor capacity to the required load.

- Optimizing compressor operating conditions.

- Implementing energy-saving measures such as variable speed drives.

9. What are the environmental considerations associated with operating a compressor?

- Noise pollution.

- Air pollution from refrigerant leaks.

- Energy consumption.

10. How do you stay up-to-date with industry best practices for compressor operations?

- Attending industry conferences and workshops.

- Reading trade journals and technical articles.

- Networking with other professionals in the field.

- Completing online training courses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Compressor Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Compressor Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Compressor Operators play a crucial role in maintaining the smooth functioning of industrial and manufacturing plants. Their key responsibilities include:

1. Operating and Monitoring Compressors

Operate and monitor a variety of compressors, including positive displacement, centrifugal, and axial flow compressors.

- Start, stop, and adjust compressor systems according to operating parameters.

- Monitor gauges, indicators, and alarms to ensure optimal compressor performance.

2. Maintaining and Troubleshooting

Perform routine maintenance tasks on compressors, including lubrication, filter changes, and inspections.

- Troubleshoot compressor problems and make necessary repairs or adjustments.

- Diagnose and resolve issues related to air pressure, temperature, and flow.

3. Safety and Environmental Compliance

Adhere to safety protocols and regulations related to compressor operation.

- Ensure proper ventilation and air handling to minimize environmental impact.

4. Communication and Record Keeping

Effectively communicate with colleagues, supervisors, and vendors.

- Maintain accurate logs and records of compressor performance and maintenance.

Interview Tips

Preparing thoroughly for an interview can significantly improve a candidate’s chances of success. Here are some essential tips:

1. Research the Company and Position

Thoroughly research the company’s industry, products/services, and company culture.

- Understand the specific job requirements and responsibilities.

- Identify the company’s mission, vision, and values.

2. Practice Answering Common Questions

Prepare for common interview questions related to your skills and experience.

- Use the STAR method (Situation, Task, Action, Result) to provide specific examples of your accomplishments.

- Quantify your results whenever possible to demonstrate your impact.

3. Highlight Relevant Skills and Experience

Tailor your resume and interview answers to emphasize skills and experience relevant to the job.

- Use keywords from the job description in your resume and interview responses.

- Provide examples of how you have successfully handled similar job responsibilities in the past.

4. Demonstrate Enthusiasm and Professionalism

Show genuine interest in the position and the company.

- Be polite, courteous, and respectful to the interviewer.

- Maintain eye contact and an upright posture.

- Follow up with a thank-you note after the interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Compressor Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.