Feeling lost in a sea of interview questions? Landed that dream interview for Steam Plant Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Steam Plant Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

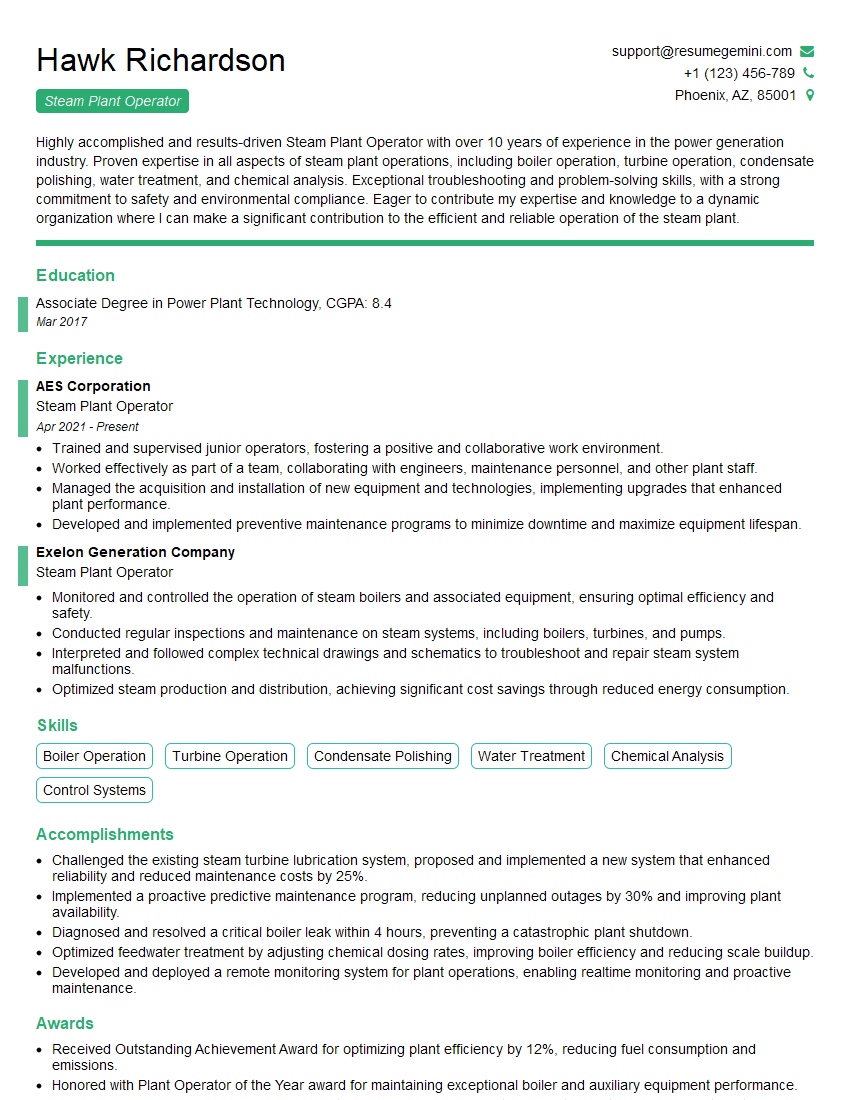

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Steam Plant Operator

1. How do you maintain the proper water chemistry in a steam boiler?

I maintain proper water chemistry in a steam boiler by adhering to the following steps:

- Regularly monitoring water quality parameters like pH, conductivity, and dissolved oxygen levels.

- Performing chemical analysis to identify impurities and determine appropriate treatment methods.

- Adding chemicals such as corrosion inhibitors, scale inhibitors, and pH adjusters to control water chemistry.

- Implementing blowdown procedures to remove impurities and maintain proper concentration levels.

- Monitoring the performance of water treatment equipment, including filters, ion exchangers, and deaerators.

2. Describe the different types of steam traps and their applications.

Mechanical Steam Traps

- Float and thermostatic traps: Used for high-pressure applications and where condensate removal is critical.

- Inverted bucket traps: Suitable for medium-pressure systems and applications requiring continuous condensate removal.

- Disc traps: Compact and reliable, used in low-pressure systems and condensate return lines.

Thermostatic Steam Traps

- Bimetallic traps: Respond quickly to temperature changes, used in tracing lines.

Thermodynamic Steam Traps

- Controlled flash traps: Used in high-pressure systems to prevent water hammer.

3. Explain the principles of operation of a steam turbine.

A steam turbine operates on the principle of converting the thermal energy of steam into mechanical energy. Key components include:

- Nozzle: Expands steam to create high velocity.

- Rotor Blades: Capture the kinetic energy of the steam, causing rotation.

- Stator Blades: Direct the steam flow to the next stage.

The high-pressure steam enters the nozzle, expands, and accelerates. This high-velocity steam impinges on the rotor blades, transferring energy and causing the rotor to rotate. The steam then flows through stator blades, which redirect it to the next stage of blades. This process repeats, extracting energy from the steam and converting it into mechanical rotation.

4. What are the different types of boiler feed pumps and their advantages?

Centrifugal Pumps

- Advantages: High flow rates, efficient at high pressures.

Positive Displacement Pumps

- Advantages: Can handle high viscosities, good for low flow rates.

Turbine-Driven Pumps

- Advantages: High efficiency, reduced maintenance.

Variable Speed Pumps

- Advantages: Energy savings, improved process control.

5. Describe the safety procedures you must follow when working on a steam system.

- Lock out and tag out all energy sources.

- Depressurize the system and allow it to cool.

- Verify isolation and absence of pressure using appropriate instruments.

- Wear appropriate personal protective equipment (PPE), including flame-resistant clothing, gloves, and safety glasses.

- Have a clear understanding of the system and the work to be performed.

- Follow established procedures and protocols.

- Be aware of potential hazards, such as steam burns, boiler explosions, and chemical leaks.

- Never work alone and always inform a supervisor of the work being performed.

6. What are the common problems encountered in steam systems and how do you troubleshoot them?

Problem: Low steam pressure

- Check fuel supply, burner operation, and boiler water level.

- Inspect for leaks in the system.

Problem: High steam pressure

- Check pressure relief valves and safety systems.

- Adjust boiler controls and reduce fuel input.

Problem: Boiler water level fluctuations

- Check for leaks in the feedwater system.

- Inspect the operation of feedwater pumps and controls.

7. What are the key performance indicators (KPIs) for a steam plant and how do you monitor them?

KPIs:

- Boiler efficiency

- Steam pressure and temperature

- Fuel consumption

- Water quality

- Emissions

Monitoring:

- Use instrumentation and sensors to collect data.

- Implement data logging and analysis systems.

- Conduct regular inspections and testing.

8. How do you manage and optimize the combustion process in a steam boiler?

I manage and optimize the combustion process in a steam boiler through the following steps:

- Maintaining proper air-fuel ratio to ensure complete combustion and minimize emissions.

- Monitoring and adjusting burner settings to achieve optimal flame characteristics.

- Performing regular combustion analysis to assess efficiency and identify areas for improvement.

- Implementing fuel additives or advanced combustion technologies to enhance performance.

- Ensuring proper maintenance of combustion equipment, including burners, fuel lines, and air registers.

9. Explain the importanciace of regular maintenance and inspection of steam systems.

Regular maintenance and inspection of steam systems are crucial for several reasons:

- Safety: To prevent accidents and ensure the safety of personnel and equipment.

- Reliability: To minimize downtime and maintain optimal system performance.

- Efficiency: To identify and address inefficiencies, reducing energy consumption and operating costs.

- Compliance: To meet regulatory requirements and industry standards.

- Extended lifespan: To prolong the life of the system and its components.

10. Describe the process of starting up and shutting down a steam boiler.

Starting Up:

- Check system components and ensure they are in good working order.

- Fill the boiler with water and preheat it gradually.

- Light the burner and adjust fuel and air supply for proper combustion.

- Monitor boiler pressure, temperature, and water level.

Shutting Down:

- Gradually reduce fuel input and allow the boiler to cool.

- Depressurize the boiler and blow down the water.

- Secure the burner and fuel supply.

- Perform post-shutdown inspections and maintenance as required.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Steam Plant Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Steam Plant Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Steam Plant Operators are responsible for the safe and efficient operation of steam-generating equipment in power plants and industrial facilities. Their primary duties include:

1. Equipment Operation and Maintenance

Starting up, shutting down, and operating boilers, turbines, condensers, and other steam-generating equipment

- Monitoring equipment performance and making adjustments to ensure optimal efficiency

- Performing routine maintenance and repairs on equipment to prevent breakdowns and ensure reliable operation

2. Process Monitoring and Control

Monitoring and controlling steam pressure, temperature, and flow rates to maintain process stability

- Analyzing data and making operational decisions to optimize steam generation and distribution

- Responding to process upsets and taking corrective actions to restore normal operating conditions

3. Safety and Compliance

Ensuring that all equipment is operated safely and in compliance with industry regulations and standards

- Identifying and addressing potential hazards and implementing safety protocols

- Participating in safety training and drills to maintain a safe work environment

4. Troubleshooting and Problem-Solving

Diagnosing and resolving equipment malfunctions and process issues to minimize downtime and ensure efficient operation

- Using test equipment and diagnostic tools to identify the root cause of problems

- Developing and implementing effective solutions to restore operations and prevent future issues

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Steam Plant Operator position:

1. Research the Company and Industry

Before the interview, take the time to learn about the company and the industry you are applying to. This will demonstrate your interest in the position and your knowledge of the field.

- Visit the company’s website and social media pages to understand their culture and values.

- Read industry publications and articles to stay up-to-date with current trends and technologies.

2. Practice Your Responses

Take some time to think about the potential interview questions you may be asked. Prepare your responses in advance so that you can deliver them clearly and confidently.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples from your previous experience.

- Practice your responses aloud or with a friend to gain confidence in your delivery.

3. Highlight Your Skills and Experience

During the interview, make sure to emphasize your skills and experience that are relevant to the Steam Plant Operator position.

- Quantify your accomplishments and provide concrete examples of your contributions.

- Discuss any certifications or training you have received that demonstrate your competence.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your interest in the position and your engagement in the conversation.

- Prepare questions about the company’s operations, their training programs, or their growth plans.

- Avoid asking generic questions that can be easily answered by browsing the company’s website.

5. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Dress professionally and be respectful of the interviewer’s time.

- Express your interest in the position and explain why you are a suitable candidate.

- Thank the interviewer for their time and consideration.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Steam Plant Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!