Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Furnace Process Plant Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Furnace Process Plant Operator so you can tailor your answers to impress potential employers.

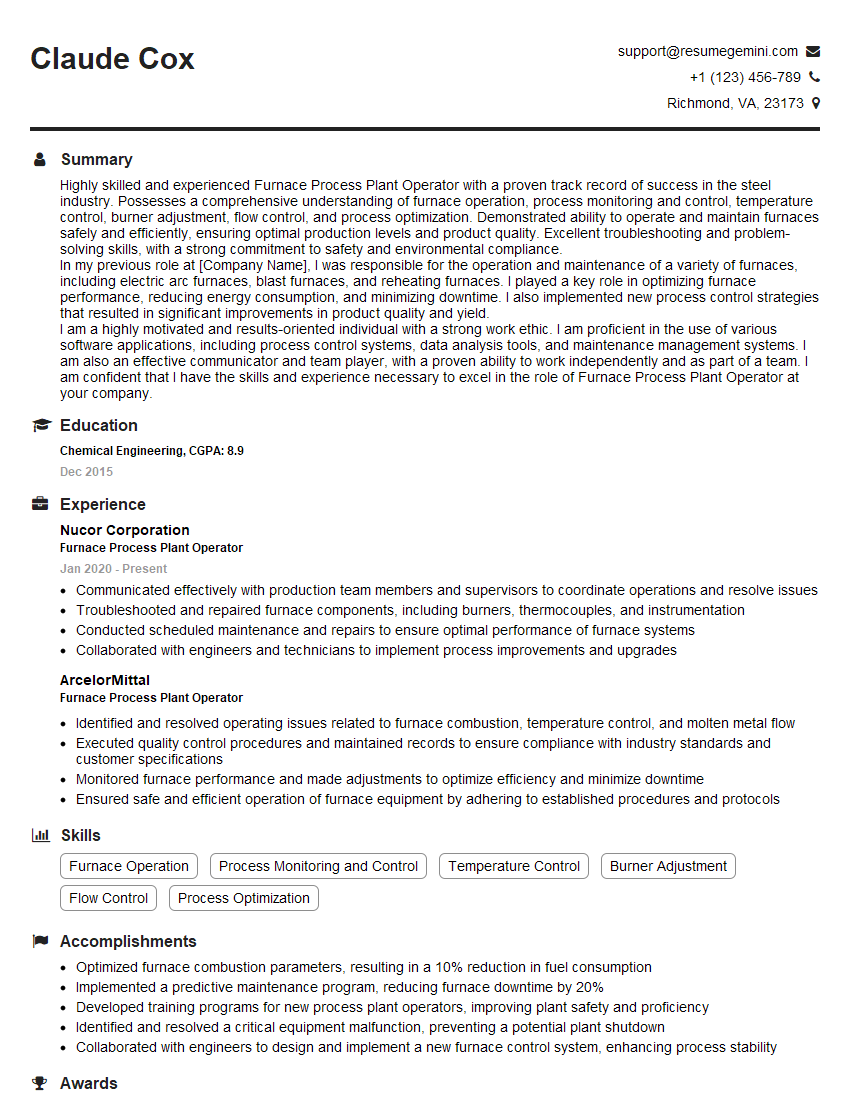

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Furnace Process Plant Operator

1. What are the key responsibilities of a Furnace Process Plant Operator?

As a Furnace Process Plant Operator, my primary responsibilities involve:

- Monitoring and controlling furnace operations to ensure efficient and safe production

- Performing routine maintenance and troubleshooting to maintain equipment reliability

- Adhering to established safety protocols and procedures to minimize risks

- Calibrating and maintaining instrumentation to ensure accurate measurements

- Communicating with other plant personnel and supervisors to coordinate operations

- Maintaining a clean and organized work environment

2. Describe the various types of furnaces used in a process plant.

Electric Arc Furnace

- Uses electric arcs to melt scrap metal

- Produces high-quality steel

Induction Furnace

- Heats metal using electromagnetic induction

- Used for melting, alloying, and heat treatment

Blast Furnace

- Used for iron production

- Injects hot air into a furnace to oxidize and reduce iron ore

Reheating Furnace

- Heats metal before further processing

- Improves workability and reduces defects

3. Explain the principles of combustion and how they apply to furnace operations.

Combustion is the chemical process of burning fuel to generate heat. In furnace operations, the fuel is typically natural gas or fuel oil. The principles of combustion include:

- Fuel must be present

- Oxygen must be present

- Heat must be present

- Flame must be sustained

By controlling the fuel, oxygen, and heat input, furnace operators can optimize combustion efficiency and minimize emissions.

4. What are the different types of fuels used in furnaces and how do they compare in terms of efficiency and cost?

- Natural Gas: Clean-burning, efficient, and relatively inexpensive

- Fuel Oil: Less efficient than natural gas, higher emissions, but more stable flame

- Coal: Least efficient, highest emissions, but lowest cost

- Electricity: Electric furnaces are very efficient, but have high operating costs

The choice of fuel depends on factors such as availability, cost, efficiency, and environmental regulations.

5. Describe the safety precautions that must be taken when operating a furnace.

- Wear appropriate personal protective equipment (PPE)

- Keep flammable materials away from the furnace

- Never enter a furnace without proper ventilation

- Be aware of the potential for explosions and fires

- Follow all established safety protocols and procedures

By adhering to safety precautions, furnace operators can minimize risks and ensure a safe work environment.

6. What types of instrumentation are commonly used in furnace operations and how are they used?

- Temperature Sensors: Measure and control furnace temperature

- Flow Meters: Measure the flow rate of fuel and air

- Pressure Gauges: Measure the pressure in the furnace and fuel lines

- Oxygen Analyzers: Measure the oxygen content in the furnace atmosphere

- Combustion Analyzers: Measure the efficiency of combustion

These instruments are used to monitor and control furnace operations, ensuring efficient and safe production.

7. Describe the maintenance procedures that are typically performed on furnaces.

- Regular cleaning: Remove scale and debris to maintain heat transfer efficiency

- Lubrication: Lubricate moving parts to reduce wear and tear

- Calibration: Calibrate instrumentation to ensure accurate readings

- Inspection: Inspect for cracks, corrosion, or other damage

- Repair: Perform necessary repairs to ensure safe and efficient operation

Regular maintenance extends the life of the furnace and minimizes downtime.

8. How do you troubleshoot common problems that occur in furnace operations?

- Furnace not heating properly: Check fuel supply, air flow, and temperature sensors

- Fluctuating temperatures: Inspect insulation, calibrate instrumentation, or check fuel quality

- Excessive smoke or emissions: Adjust fuel-to-air ratio, inspect burners, or check for leaks

- Equipment failure: Identify the faulty component, repair or replace as necessary

Effective troubleshooting requires a combination of knowledge, experience, and problem-solving skills.

9. How do you stay up-to-date on the latest advancements in furnace technology?

- Attend industry conferences and trade shows

- Read technical journals and articles

- Participate in online forums and discussions

- Consult with equipment manufacturers and suppliers

Continuous learning is essential for staying abreast of new technologies that can improve furnace operations.

10. What is your understanding of the environmental regulations that apply to furnace operations?

I am familiar with the environmental regulations that apply to furnace operations, including:

- Clean Air Act: Regulates air emissions, including particulate matter, sulfur dioxide, and nitrogen oxides

- Clean Water Act: Regulates water discharges from industrial facilities

- Resource Conservation and Recovery Act: Regulates the generation, storage, and disposal of hazardous waste

I am committed to complying with all applicable environmental regulations to minimize the environmental impact of furnace operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Furnace Process Plant Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Furnace Process Plant Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Furnace Process Plant Operators play a vital role in regulating and maintaining the smooth operation of furnace processes, ensuring the efficient production of materials such as metals, glass, and ceramics.

1. Equipment Monitoring and Control

Monitor and control furnaces, kilns, and other equipment used in the heating and processing of materials.

- Adjust temperature, airflow, and other process parameters to optimize furnace performance.

- Troubleshoot and resolve equipment malfunctions promptly to minimize production disruptions.

2. Process Optimization

Analyze production data and identify areas for improvement in furnace performance and efficiency.

- Conduct experiments and tests to determine optimal operating conditions.

- Implement process modifications to reduce energy consumption, increase production yield, and improve product quality.

3. Quality Control

Perform quality checks on finished products, ensuring they meet specifications and customer requirements.

- Conduct visual inspections, dimensional measurements, and other tests.

- Document and report any deviations from established standards.

4. Safety and Maintenance

Adhere to all safety regulations and ensure a safe working environment in the furnace plant.

- Perform regular maintenance and repairs on equipment.

- Train new employees and maintain a high level of safety awareness throughout the facility.

Interview Tips

Preparing for an interview for a Furnace Process Plant Operator position requires a combination of technical knowledge, industry experience, and effective communication skills. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Thoroughly research the company you are applying to and the industry in which they operate. This will demonstrate your interest in the position and your understanding of the field.

- Visit the company website to learn about their products, services, and values.

- Read industry publications and news articles to stay up-to-date on the latest advancements and trends.

2. Highlight Your Technical Expertise

Emphasize your technical skills and experience in operating furnace processes and equipment. Use specific examples to demonstrate your ability to troubleshoot problems and optimize production.

- Quantify your accomplishments with metrics, such as increased production yield or reduced energy consumption.

- Discuss your knowledge of different types of furnaces, including their design, operation, and maintenance.

3. Showcase Your Problem-Solving Abilities

Interviews often involve scenario-based questions to assess your problem-solving abilities. Be prepared to discuss how you would handle common challenges in a furnace plant operation.

- Describe a situation where you successfully identified and resolved a furnace malfunction.

- Explain your approach to optimizing furnace performance under varying production conditions.

4. Emphasize Safety and Quality Control

Safety and quality are paramount in a furnace plant environment. Highlight your commitment to safety and your experience in maintaining a safe working environment.

- Discuss your knowledge of industry safety regulations and your track record of adhering to them.

- Explain your approach to quality control, including inspection methods and procedures.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Furnace Process Plant Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.