Are you gearing up for a career in Regasification Plant Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Regasification Plant Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

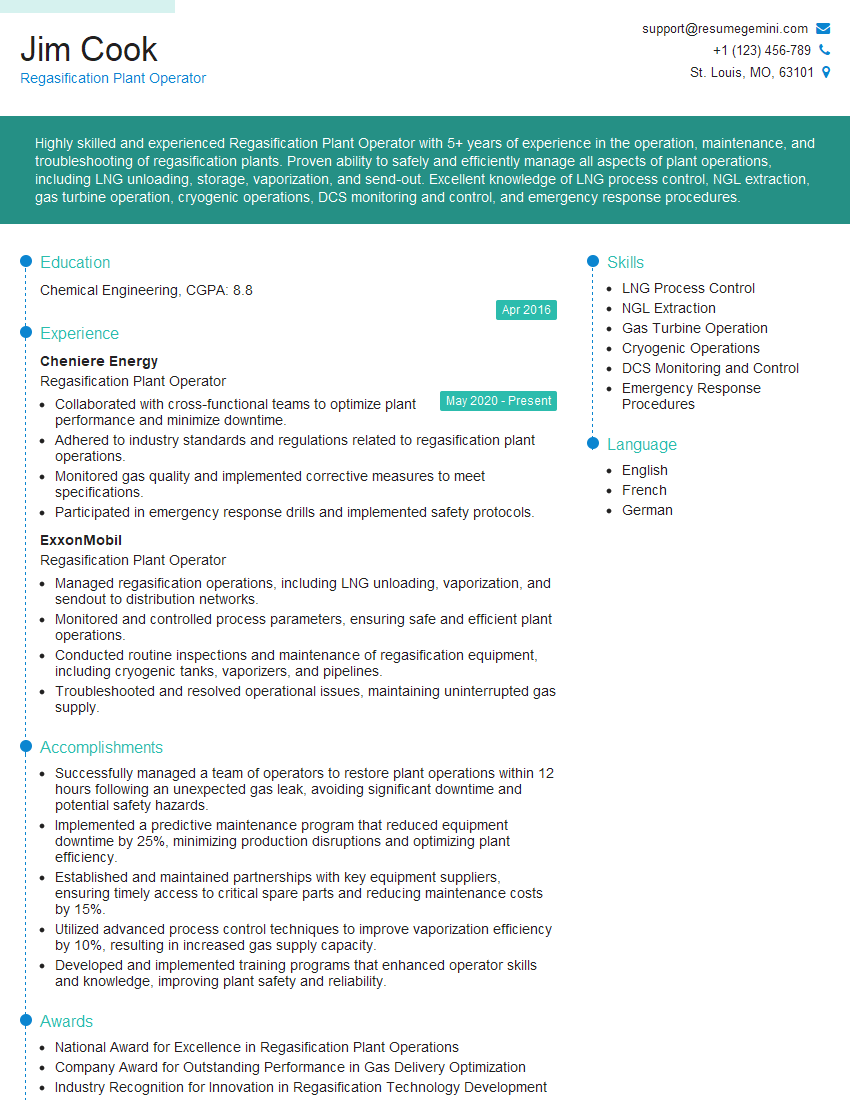

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Regasification Plant Operator

1. How do you handle and prevent the risk of LNG spills during the regasification process?

- Implement robust emergency response plans and procedures.

- Conduct regular safety drills and training for personnel.

- Use reliable equipment and follow strict maintenance schedules.

- Monitor the system continuously for leaks and abnormalities.

- Establish clear communication protocols for reporting and responding to spills.

2. Describe the key operating parameters and safety systems you monitor as a Regasification Plant Operator.

LNG Temperature and Pressure

- Maintain optimal LNG temperature to prevent freezing or vaporization.

- Ensure LNG pressure is within safe operating limits.

Flow Rates

- Monitor LNG and gas flow rates to optimize regasification and prevent overpressure.

- Adjust flow rates based on demand and system constraints.

Safety Systems

- Monitor the status of safety systems, such as fire alarms, gas detectors, and emergency shutdown valves.

- Perform regular testing and maintenance of these systems to ensure reliability.

3. How do you ensure the efficient and safe regasification of LNG to meet fluctuating demand requirements?

- Develop and implement operating procedures to optimize regasification rates.

- Use automated control systems to adjust operating parameters based on demand.

- Monitor system performance and make adjustments as needed to maintain efficiency and safety.

- Coordinate with other departments, such as storage and distribution, to ensure seamless operations.

4. Describe the process of loading and unloading LNG tankers at the regasification terminal.

Loading:

- Prepare the LNG tanker and terminal for loading.

- Transfer LNG from the storage tank to the tanker via cryogenic hoses.

- Monitor the loading process and ensure safety protocols are followed.

Unloading:

- Receive the LNG tanker and prepare for unloading.

- Connect the tanker to the regasification system using cryogenic hoses.

- Monitor the unloading process and ensure safe and efficient transfer of LNG.

5. How do you maintain and troubleshoot the equipment used in the regasification process?

- Follow manufacturer’s maintenance schedules for all equipment.

- Conduct regular inspections and tests to detect potential problems early.

- Use specialized tools and techniques to troubleshoot equipment malfunctions.

- Work closely with maintenance technicians to resolve complex issues.

6. Describe the environmental regulations and safety standards that apply to regasification plant operations.

- Adhere to local, national, and international environmental regulations to minimize emissions.

- Implement safety measures and procedures to prevent accidents and protect the environment.

- Monitor environmental parameters, such as air and water quality, to ensure compliance.

- Report any environmental incidents or spills promptly and follow established response protocols.

7. How do you communicate effectively with other team members and stakeholders in the regasification process?

- Use clear and concise communication methods, both verbal and written.

- Provide regular updates on system status and any potential issues.

- Participate in team meetings and discussions.

- Build and maintain positive relationships with colleagues and stakeholders.

8. Describe the importance of data analysis and reporting in regasification plant operations.

- Analyze plant data to identify trends and areas for improvement.

- Generate reports on plant performance, safety, and environmental compliance.

- Use data to optimize operating parameters and reduce costs.

- Share data and insights with management and other stakeholders.

9. How do you stay up-to-date with the latest technologies and best practices in regasification plant operations?

- Attend industry conferences and workshops.

- Read technical publications and journals.

- Participate in online forums and discussions.

- Collaborate with colleagues and other professionals in the field.

10. Describe a challenging situation you faced as a Regasification Plant Operator and how you resolved it.

Situation:

- Unexpected increase in demand led to high pressure in the regasification system.

Resolution:

- Quickly adjusted operating parameters to reduce pressure.

- Communicated with downstream operators to coordinate flow rates.

- Monitored the system closely and made further adjustments as needed.

- Resolved the issue without any safety incidents or damage to equipment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Regasification Plant Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Regasification Plant Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Regasification Plant Operators play a critical role in ensuring the safe and efficient operation of regasification plants. Their key responsibilities include:

1. Plant Operations

Operate and monitor all plant equipment, including compressors, pumps, and heat exchangers.

- Maintain and troubleshoot plant equipment to ensure optimal performance.

- Conduct routine inspections and maintenance to prevent breakdowns and ensure compliance with safety regulations.

2. Process Control

Monitor and control the flow of liquefied natural gas (LNG) through the regasification process.

- Adjust process parameters to optimize efficiency and ensure adherence to quality standards.

- Monitor and analyze plant data to identify potential issues and implement corrective actions.

3. Emergency Response

Respond swiftly and effectively to emergency situations.

- Identify and assess potential hazards and implement appropriate safety protocols.

- Coordinate with emergency responders and follow established emergency response plans.

4. Safety and Compliance

Adhere to all safety regulations and industry best practices.

- Wear appropriate personal protective equipment and follow established safety procedures.

- Maintain a clean and organized work area to minimize risks.

Interview Tips

Preparing thoroughly for a Regasification Plant Operator interview is crucial to showcase your skills and increase your chances of success.

1. Research the Company and Role

Research the company’s background, values, and industry reputation.

- Study the specific requirements of the Regasification Plant Operator role and identify the key responsibilities.

- Demonstrate your understanding of the regasification process and the role of the operator in it.

2. Practice Answering Common Questions

Anticipate common interview questions and prepare concise and well-structured answers.

- Describe your experience in operating and maintaining industrial equipment.

- Explain your understanding of process control and monitoring techniques.

- Share examples of how you have handled emergency situations in a plant environment.

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements.

- Quantify your accomplishments using specific metrics whenever possible.

- Showcase your ability to work in a team environment and collaborate with others.

4. Ask Thoughtful Questions

Prepare thoughtful questions to ask the interviewer.

- Inquire about the company’s future plans and growth prospects.

- Ask about the specific challenges and opportunities associated with the Regasification Plant Operator role.

Next Step:

Now that you’re armed with the knowledge of Regasification Plant Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Regasification Plant Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini