Feeling lost in a sea of interview questions? Landed that dream interview for Petroleum Refining Equipment Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Petroleum Refining Equipment Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

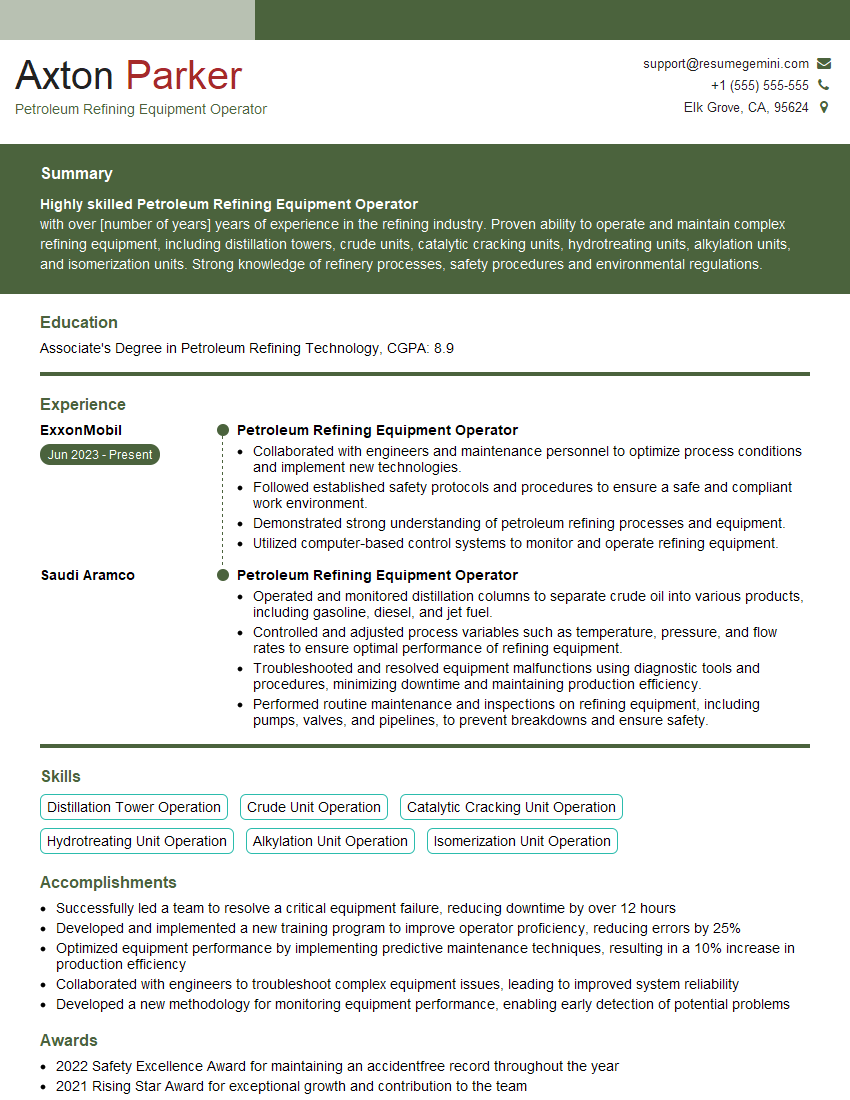

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Petroleum Refining Equipment Operator

1. Describe the responsibilities of a Petroleum Refining Equipment Operator.

As a Petroleum Refining Equipment Operator, my primary responsibilities involve:

- Monitoring and controlling the operation of petroleum refining equipment, including distillation columns, reactors, and heat exchangers.

- Maintaining equipment by performing routine maintenance and repairs.

- Troubleshooting equipment malfunctions and implementing corrective actions.

- Ensuring compliance with safety and environmental regulations.

- Working as part of a team to ensure efficient and safe operation of the refinery.

2. Explain the principles of fractional distillation and how it is used in petroleum refining.

Fractional distillation is a process used to separate components of a liquid mixture based on their boiling points. In petroleum refining, fractional distillation is used to separate various hydrocarbons present in crude oil.

Principle of Fractional Distillation:

- The mixture is heated in a distillation column.

- Components with lower boiling points vaporize and rise up the column.

- Components with higher boiling points remain in the liquid phase.

- Condensers at different heights collect the vaporized components based on their boiling points.

3. Describe the different types of reactors used in petroleum refining and their functions.

Petroleum refining employs several types of reactors, each designed for specific chemical reactions:

- Hydrocracking Reactor: Converts heavy hydrocarbons into lighter, more valuable products using hydrogen and a catalyst.

- Catalytic Reforming Reactor: Increases the octane number of gasoline by converting low-octane hydrocarbons into high-octane components.

- Alkylation Reactor: Combines light olefins with isobutane to produce high-octane gasoline components.

- Polymerization Reactor: Converts olefins into polymers, which are used as additives in plastics and lubricants.

4. Explain the importance of maintaining accurate records and logs as a Petroleum Refining Equipment Operator.

Accurate record-keeping is crucial because it:

- Provides a history of equipment operation and maintenance.

- Helps identify and resolve equipment issues promptly.

- Facilitates troubleshooting and optimization of the refining process.

- Serves as a source of data for compliance audits and regulatory reporting.

- Ensures the safety and accountability of the equipment operation.

5. Describe the safety precautions that should be taken when operating petroleum refining equipment.

Safety is paramount in petroleum refining operations. Essential precautions include:

- Wearing appropriate personal protective equipment (PPE), including flame-resistant clothing, safety glasses, gloves, and respirators.

- Following established operating procedures and safety protocols.

- Being aware of potential hazards, such as flammable liquids, toxic gases, and high temperatures.

- Recognizing emergency situations and knowing the proper response procedures.

- Participating in regular safety training and drills.

6. Explain how you would troubleshoot a problem with a distillation column.

When troubleshooting a distillation column, I would follow a systematic approach:

- Check the operating conditions (temperature, pressure, flow rates) against the specified parameters.

- Inspect the column for any leaks, blockages, or fouling.

- Review the feedstock composition and ensure it matches the design specifications.

- Analyze the product streams to identify any deviations from the expected composition.

- Consult with colleagues and technical experts to gather insights and potential solutions.

7. Describe the role of automation in modern petroleum refining operations.

Automation plays a significant role in enhancing the efficiency and safety of petroleum refining operations.

- Process Control Systems: Automated systems monitor and control process variables, optimizing equipment performance and product quality.

- Data Analytics: Advanced data analysis tools provide insights into process performance, enabling predictive maintenance and process optimization.

- Remote Monitoring: Centralized systems allow operators to monitor and control equipment from remote locations, enhancing operational flexibility.

- Safety Systems: Automated safety systems detect hazardous conditions and initiate appropriate responses, reducing risks.

8. Explain the importance of environmental compliance in petroleum refining operations.

Environmental compliance is crucial in petroleum refining to minimize the impact on the surroundings.

- Air Pollution Control: Refineries must adhere to regulations that limit emissions of pollutants such as sulfur dioxide and nitrogen oxides.

- Water Pollution Control: Wastewater treatment facilities ensure that effluents meet environmental standards and protect aquatic ecosystems.

- Waste Management: Refineries must properly dispose of hazardous and non-hazardous wastes to prevent environmental contamination.

- Landfill Reclamation: Proper landfill management minimizes environmental risks associated with waste disposal.

9. Describe your experience in working with different types of pumps and compressors used in petroleum refining.

In my previous role, I gained extensive experience with various pumps and compressors:

- Centrifugal Pumps: Used for high-volume liquid transfer, such as crude oil and refined products.

- Reciprocating Pumps: Employed for high-pressure applications, such as boiler feedwater and injection systems.

- Screw Compressors: Used for gas compression in various refining processes, including gas turbine engines and refrigeration systems.

- Centrifugal Compressors: Employed for large-scale gas compression, such as in natural gas processing.

10. Explain how you would handle an emergency situation, such as a fire or chemical spill, in a petroleum refining facility.

In the event of an emergency, I would prioritize the following actions:

- Ensure Safety: Evacuate the area, alert emergency responders, and establish a safe perimeter.

- Assess the Situation: Gather information about the incident, including the nature of the emergency, potential hazards, and available resources.

- Implement Response Plan: Follow established emergency response protocols, such as activating fire suppression systems or containing chemical spills.

- Communicate Effectively: Inform supervisors, emergency services, and relevant personnel about the situation and response actions.

- Coordinate Recovery: Once the emergency has been contained, assist in cleanup and recovery efforts to minimize further risks and restore normal operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Petroleum Refining Equipment Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Petroleum Refining Equipment Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Petroleum Refining Equipment Operators are responsible for coordinating and overseeing the operation of equipment used in the refining of petroleum products. Their primary goal is to ensure efficient and safe operations, as well as to maintain the quality of petroleum products.

1. Equipment Operation and Maintenance

Operate and maintain a variety of refining equipment, such as distillation columns, reactors, heat exchangers, and pumps.

Monitor and control process variables, such as temperature, pressure, flow rate, and product quality.

Perform routine maintenance and repairs to ensure equipment is operating optimally.

2. Process Monitoring and Control

Monitor refining processes and make adjustments as needed to optimize production and product quality.

Analyze process data and identify areas for improvement.

Maintain records of process operations and equipment performance.

3. Safety and Environmental Compliance

Adhere to all safety regulations and procedures.

Operate equipment in a manner that minimizes environmental impact.

Report any potential hazards or spills immediately.

4. Troubleshooting and Problem-Solving

Troubleshoot equipment malfunctions and process problems.

Implement solutions to restore production and ensure product quality.

Collaborate with maintenance personnel to resolve complex issues.

Interview Tips

Preparing for an interview is a crucial step in securing your dream job. Here are some tips to help you ace your interview for a position as a Petroleum Refining Equipment Operator:

1. Research the company and the role

Thoroughly research the company’s history, current projects, and corporate culture. This will allow you to demonstrate your enthusiasm and understanding of the organization.

Review the job description carefully and identify the key skills and qualifications required. Highlight these in your resume and cover letter.

2. Practice your answers to common interview questions

Anticipate common interview questions and prepare your responses in advance. Use the STAR method (Situation, Task, Action, Result) to provide concrete examples of your experience.

For instance, when asked about your problem-solving abilities, you could describe a specific situation where you identified and resolved an issue related to petroleum refining equipment.

3. Quantify your accomplishments

Use specific numbers and metrics to quantify your accomplishments when describing your experience. This will make your responses more impactful and memorable.

For example, instead of saying “I improved process efficiency,” you could say, “I implemented a new process control strategy that resulted in a 10% increase in production yield.”

4. Showcase your safety and environmental awareness

Emphasize your commitment to safety and environmental compliance. Provide examples of how you have proactively ensured the safe operation of equipment and minimized environmental impact.

You could highlight your participation in safety training programs or your efforts to reduce waste generation.

5. Prepare industry-specific questions

In addition to general interview questions, prepare industry-specific questions that demonstrate your knowledge of petroleum refining equipment and processes.

For instance, you could ask about the company’s latest investments in refining technology or their approach to reducing carbon emissions in their operations.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Petroleum Refining Equipment Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!