Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Safety Equipment Testing Specialist position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

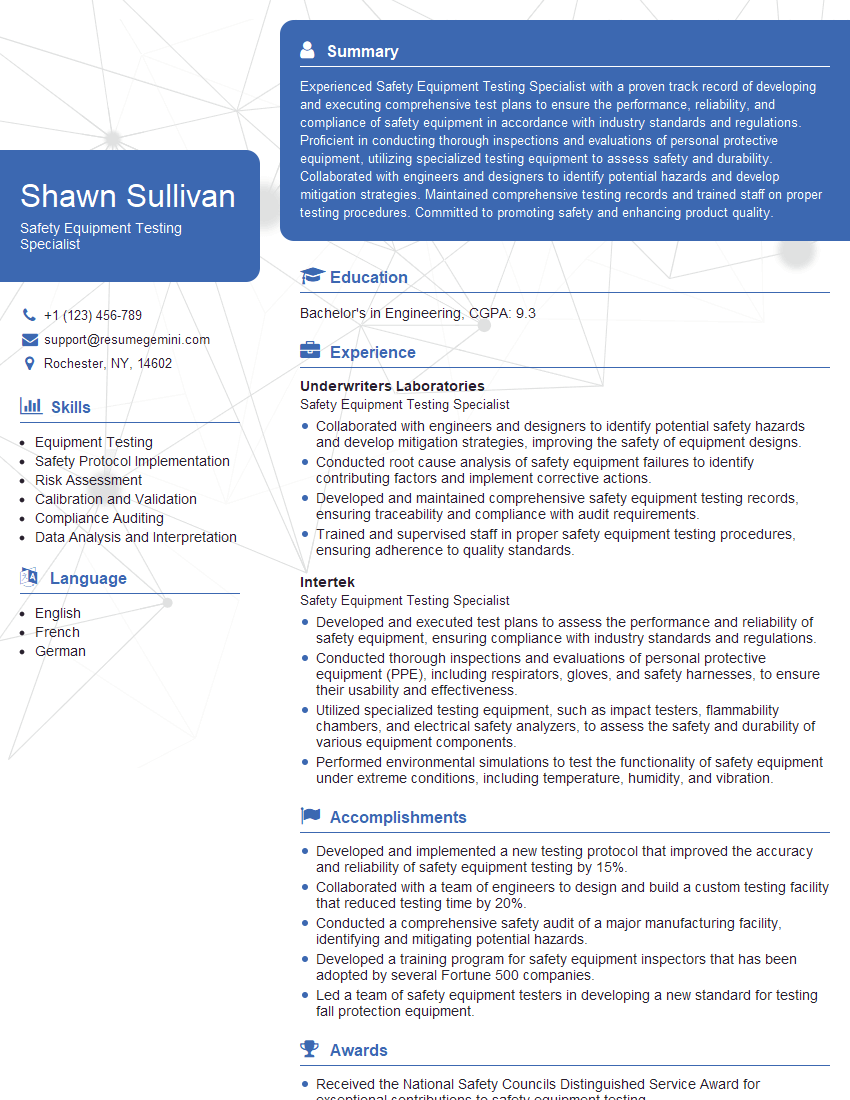

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Safety Equipment Testing Specialist

1. Describe the various safety tests you have conducted on safety equipment?

In my previous role, I conducted a range of safety tests on safety equipment, including:

- Electrical testing: to ensure that equipment met electrical safety standards, such as insulation resistance and continuity tests.

- Mechanical testing: to evaluate the strength and durability of equipment, such as drop tests and load tests.

- Environmental testing: to assess the equipment’s performance under various environmental conditions, such as temperature extremes, humidity, and vibration.

- Chemical testing: to determine the equipment’s resistance to chemicals and other hazardous substances.

- Ergonomic testing: to ensure that equipment was comfortable and easy to use.

2. Explain the importance of calibration and maintenance in safety equipment testing?

Importance of calibration

- Ensures accuracy and reliability of test results.

- Prevents false positives or negatives.

- Maintains compliance with industry standards and regulations.

Importance of maintenance

- Extends the lifespan of equipment.

- Improves equipment performance and reliability.

- Reduces the risk of equipment failure and accidents.

3. Describe the use of specialized equipment in safety equipment testing?

In safety equipment testing, I have used specialized equipment such as:

- Electrical safety analyzers: to conduct electrical testing, such as insulation resistance and continuity tests.

- Mechanical testing machines: to perform mechanical testing, such as drop tests and load tests.

- Environmental chambers: to simulate various environmental conditions, such as temperature extremes, humidity, and vibration.

- Chemical testing apparatus: to conduct chemical testing, such as corrosion resistance tests.

- Ergonomic assessment tools: to evaluate the comfort and usability of equipment.

4. How do you stay updated on the latest safety equipment testing standards and regulations?

I stay updated on the latest safety equipment testing standards and regulations through the following methods:

- Attending industry conferences and workshops: to learn about new testing methods and technologies.

- Reading industry publications and journals: to stay informed about the latest research and developments.

- Participating in professional organizations: to connect with other professionals and share knowledge.

- Consulting with regulatory agencies: to ensure compliance with the latest requirements.

5. Describe the importance of documentation in safety equipment testing?

Documentation is essential in safety equipment testing for the following reasons:

- Provides a record of testing procedures and results: for reference and traceability.

- Facilitates communication: between team members, clients, and regulatory agencies.

- Supports compliance: with industry standards and regulations.

- Enables continuous improvement: by identifying areas for improvement in testing processes.

6. How do you ensure the quality and accuracy of your safety equipment testing results?

I ensure the quality and accuracy of my safety equipment testing results through the following practices:

- Following standardized testing procedures: to maintain consistency and reliability.

- Using calibrated and maintained equipment: to ensure accurate and reliable measurements.

- Documenting all testing activities: to provide a transparent and traceable record.

- Conducting regular internal audits: to identify and address any potential issues.

- Seeking external accreditation: to demonstrate competence and compliance with industry standards.

7. How do you handle discrepancies or deviations from expected results in safety equipment testing?

When I encounter discrepancies or deviations from expected results in safety equipment testing, I follow the following steps:

- Investigate the cause: by reviewing the testing procedure, equipment, and environmental conditions.

- Repeat the test: to confirm the discrepancy or deviation.

- Consult with colleagues or experts: to seek their insights and advice.

- Document the findings: in the test report, including the cause and any corrective actions taken.

- Implement corrective actions: to prevent similar discrepancies or deviations in the future.

8. Describe your experience with developing and implementing safety equipment testing programs?

In my previous role, I was responsible for developing and implementing a comprehensive safety equipment testing program. The program included the following components:

- Test plan development: outlining the testing objectives, scope, and methodology.

- Test equipment selection and calibration: to ensure accuracy and reliability.

- Testing procedures: based on industry standards and best practices.

- Data collection and analysis: to evaluate safety equipment performance.

- Report generation: summarizing test results and providing recommendations.

9. How do you manage the workload and prioritize tasks in a fast-paced safety equipment testing environment?

In a fast-paced safety equipment testing environment, I manage my workload and prioritize tasks as follows:

- Planning and scheduling: using a task management system to track deadlines and allocate resources.

- Delegation: assigning tasks to team members based on their skills and expertise.

- Time management techniques: using tools such as the Pomodoro technique to improve efficiency.

- Communication: keeping stakeholders informed of progress and potential bottlenecks.

- Flexibility: adapting to changing priorities and workload demands.

10. How do you stay motivated and engaged in the field of safety equipment testing?

I stay motivated and engaged in the field of safety equipment testing because:

- The importance of the work: I believe that my work helps to ensure the safety of workers and consumers.

- The challenges: I enjoy solving complex technical problems and finding innovative solutions.

- The learning opportunities: The field of safety equipment testing is constantly evolving, and I am eager to learn new technologies and best practices.

- The impact: I am proud to be part of an industry that makes a real difference in the world.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Safety Equipment Testing Specialist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Safety Equipment Testing Specialist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Safety Equipment Testing Specialist plays a critical role in ensuring the quality and safety of safety equipment used in various industries. Key responsibilities include:

1. Equipment Testing and Evaluation

Conduct rigorous testing and evaluation of safety equipment, such as protective clothing, respiratory devices, and fall protection gear, to ensure compliance with industry standards and regulations.

- Develop and execute comprehensive testing plans.

- Operate specialized testing equipment and analyze results to assess performance and identify potential hazards.

2. Standard Development and Compliance

Participate in the development and maintenance of industry standards and regulations related to safety equipment. Ensure that testing procedures and equipment are in accordance with established norms.

- Monitor industry developments and updates.

- Collaborate with regulatory bodies and certification agencies.

3. Data Analysis and Reporting

Collect, analyze, and interpret test data to provide insights into the performance and reliability of safety equipment. Generate comprehensive reports detailing test results and recommendations.

- Use statistical techniques and data visualization tools.

- Communicate findings effectively to stakeholders.

4. Quality Control and Improvement

Establish and maintain quality control procedures to ensure the accuracy and reliability of testing. Identify and implement process improvements to enhance efficiency and effectiveness.

- Develop and implement quality assurance protocols.

- Monitor and evaluate testing processes to identify areas for optimization.

Interview Tips

Preparing thoroughly for a Safety Equipment Testing Specialist interview is essential. Here are some key tips to help you ace the interview:

1. Research the Role and Industry

Begin by carefully reviewing the job description and conducting research on the company and industry. This will provide you with a deep understanding of the specific job requirements and the overall sector.

- Identify the key technical skills and knowledge expected.

- Explore industry trends and regulations to demonstrate your awareness.

2. Highlight Your Technical Proficiency

Emphasize your expertise in testing methodologies, equipment operation, and data analysis. Provide specific examples of the techniques you have employed and the results you have achieved.

- Showcase your experience with testing instrumentation and software.

- Discuss your ability to interpret complex data and draw insightful conclusions.

3. Demonstrate Your Standards Knowledge

Highlight your familiarity with industry standards and regulations related to safety equipment testing. Explain how you have applied this knowledge in your previous roles.

- Mention any certifications you have obtained.

- Discuss your understanding of different standards and their relevance to the testing process.

4. Emphasize Your Problem-Solving Skills

Explain how you approach and resolve challenges encountered during testing. Provide examples of situations where you identified potential issues and implemented solutions to ensure equipment performance and reliability.

- Highlight your ability to think critically and troubleshoot problems.

- Discuss your experience in developing and implementing testing protocols.

5. Prepare Industry-Specific Questions

Prepare thoughtful questions related to the industry and the specific role you are applying for. This demonstrates your interest and enthusiasm for the field and shows that you have done your homework.

- Inquire about recent industry developments.

- Ask about the company’s approach to safety equipment testing and quality assurance.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Safety Equipment Testing Specialist interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!