Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted C D Still Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

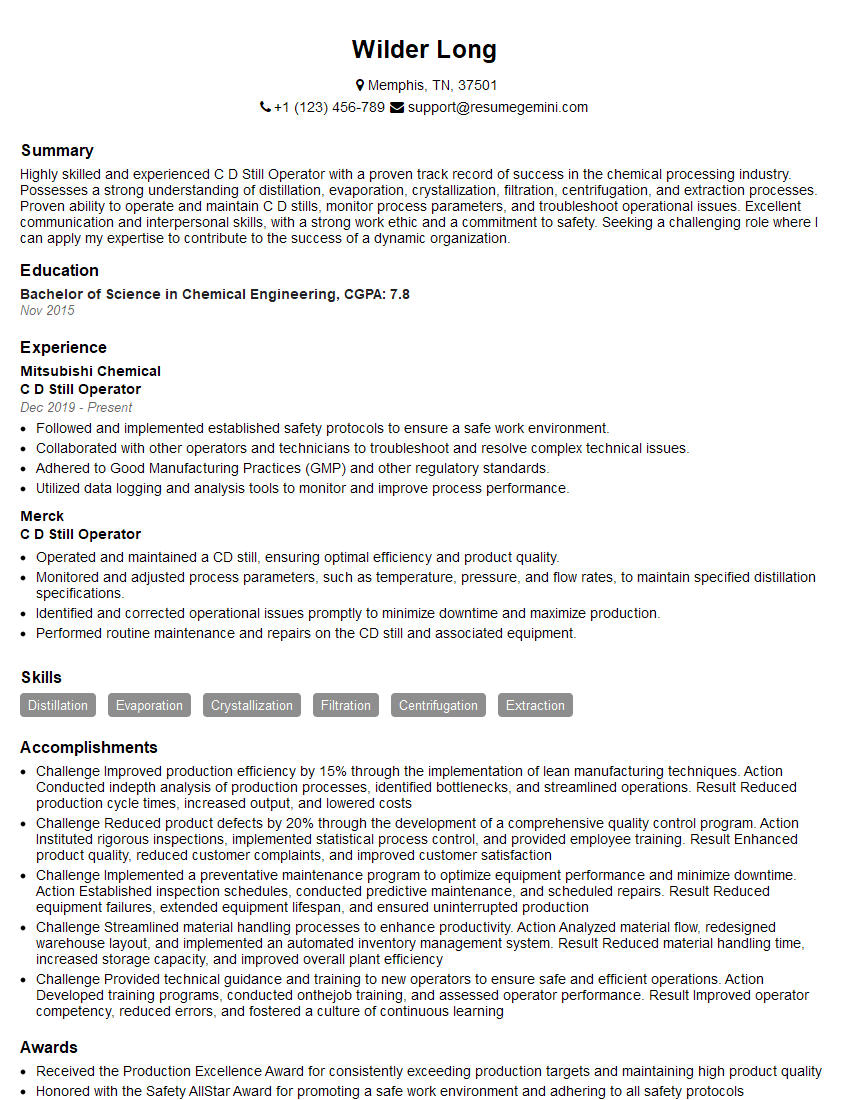

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For C D Still Operator

1. Explain the working principle of a Continuous Distillation Still (CDS)?

The Continuous Distillation Still (CDS) operates on the principle of fractional distillation. Here’s a detailed explanation of its working:

- Feed Introduction: The liquid mixture to be separated is continuously fed into the middle of the column.

- Vaporization and Condensation: The feed mixture is vaporized in the reboiler at the bottom of the column. The vapor rises up the column while the liquid falls down due to gravity.

- Separation: As the vapor rises, it encounters cooler temperatures at higher elevations in the column. This causes the more volatile components (lower boiling points) to condense and fall back into the column as reflux, while the less volatile components (higher boiling points) continue to rise.

- Multiple Stages: The column is divided into multiple stages (trays or packing) that provide additional surface area for vapor-liquid contact. This allows for efficient separation as the vapor and liquid interact multiple times.

- Reboiler and Condenser: The reboiler continuously boils the liquid at the bottom of the column to generate vapor. The condenser at the top of the column cools and condenses the vapor to produce the distillate (top product).

2. Describe the key components of a CDS and their functions?

Reboiler

- Heats the liquid feed mixture to generate vapor.

- Provides the thermal energy required for distillation.

Column

- Provides multiple stages for vapor-liquid contact.

- Facilitates the separation of components based on their boiling points.

Condenser

- Cools and condenses the vapor rising from the column.

- Produces the distillate (top product) of the distillation process.

Reflux System

- Controls the flow of condensate back into the column.

- Improves the efficiency of separation by providing additional vapor-liquid contact.

3. What are the advantages of using a CDS over a batch distillation system?

- Continuous Operation: CDS operates 24/7, allowing for continuous production of distillate.

- Higher Efficiency: The multiple stages of vapor-liquid contact in a CDS enable more efficient separation.

- Consistent Product Quality: CDS maintains a stable operating temperature and flow rate, resulting in consistent product quality.

- Scalability: CDS can be easily scaled up or down to meet varying production demands.

- Energy Efficiency: Heat recovery systems in CDS can improve energy efficiency by utilizing waste heat from the reboiler.

4. What are the typical applications of a CDS?

- Separation of liquids with similar boiling points (e.g., ethanol and water in alcohol production).

- Purification and refining of chemicals (e.g., removing impurities from organic solvents).

- Production of high-purity products (e.g., pharmaceutical intermediates).

- Recovery of valuable compounds from waste streams (e.g., solvents from industrial processes).

- Separation of azeotropic mixtures (e.g., water and ethyl acetate).

5. Explain the concept of reflux ratio and its significance in CDS operation?

Reflux ratio is the ratio of the amount of liquid refluxed back into the column to the amount of distillate withdrawn. It plays a crucial role in determining the efficiency and product purity of the CDS:

- Higher Reflux Ratio: Increases the number of vapor-liquid contacts, leading to improved separation and higher product purity.

- Lower Reflux Ratio: Decreases separation efficiency but increases the production rate of distillate.

- Optimum Reflux Ratio: Each CDS has an optimum reflux ratio that balances separation efficiency with product yield.

6. Describe the main types of trays used in CDS columns and their characteristics?

Sieve Trays

- Perforated plates with holes or slots.

- Simple design, low cost.

- Suitable for low to moderate vapor velocities.

Bubble Caps Trays

- Involve caps with slots that allow vapor to bubble through.

- Higher efficiency than sieve trays.

- Suitable for higher vapor velocities.

Valve Trays

- Use mechanically operated valves to control vapor flow.

- High efficiency and low pressure drop.

- Suitable for wide range of operating conditions.

7. What are the potential troubleshooting issues that can occur in a CDS operation?

- Flooding: Excessive liquid accumulation on trays, hindering vapor flow.

- Entrainment: Liquid droplets carried over with the vapor, leading to product contamination.

- Maldistribution: Uneven liquid distribution on trays, affecting separation efficiency.

- Fouling: Buildup of solids or impurities on trays, reducing efficiency.

- Corrosion: Damage to equipment due to chemical reactions.

8. How do you ensure the safety and efficiency of a CDS operation?

- Regular Inspection and Maintenance: Inspect trays, packings, seals, and valves regularly for wear and tear.

- Process Control: Monitor and control temperature, pressure, flow rates, and reflux ratio to maintain optimal operating conditions.

- Safety Protocols: Follow established safety procedures to prevent accidents and minimize risks associated with flammable and toxic materials.

- Training: Provide comprehensive training to operators on CDS operation, troubleshooting, and safety measures.

- Emergency Preparedness: Develop emergency response plans and conduct drills to ensure prompt and effective response to any potential incidents.

9. What is the importance of proper instrumentation and control systems in a CDS operation?

Instrumentation and control systems play a vital role in ensuring the efficient and safe operation of a CDS:

- Process Monitoring: Sensors and instruments monitor key process variables such as temperature, pressure, flow rates, and levels.

- Control Loops: Automated control loops adjust valves and actuators to maintain desired operating conditions.

- Data Acquisition and Analysis: Systems collect and analyze data to track performance and identify potential issues.

- Alarm Systems: Alerts operators to deviations from normal operating parameters, enabling timely intervention.

- Remote Monitoring and Control: Allows operators to monitor and control the CDS remotely, ensuring uninterrupted operation.

10. How do you stay updated with the latest advancements and best practices in CDS technology?

- Attend Industry Conferences and Webinars: Participate in events to learn about new technologies, trends, and case studies.

- Read Technical Journals and Publications: Stay informed about research and developments in the field.

- Network with Industry Professionals: Connect with other CDS operators, engineers, and experts to exchange knowledge and experiences.

- Vendor Training: Participate in training programs offered by equipment manufacturers to learn about new products and applications.

- Professional Development: Seek opportunities for continuing education to enhance skills and knowledge in CDS operation and technology.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for C D Still Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the C D Still Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A C D Still Operator is responsible for the effective operation of Continuous Distillation (C D) Stills, ensuring the production of high-quality distilled products while adhering to safety regulations and maintaining a clean and organized work environment.

1. Operation of C D Stills

Operate and monitor C D Stills to separate liquid mixtures through distillation processes.

- Control temperature, pressure, and flow rates to achieve desired product specifications.

- Monitor equipment performance and make necessary adjustments to optimize efficiency.

2. Product Quality Control

Test and analyze distilled products to ensure they meet established quality standards.

- Perform chemical and physical tests on samples to verify purity, composition, and other quality attributes.

- Maintain accurate records of product quality data and identify any deviations from specifications.

3. Equipment Maintenance

Conduct routine maintenance and inspections on C D Stills and related equipment.

- Clean, calibrate, and repair stills, pumps, valves, and other components.

- Identify any potential issues and take necessary preventive measures to ensure smooth operation.

4. Safety and Compliance

Adhere to all safety regulations and procedures related to the operation of C D Stills.

- Wear appropriate safety gear and follow established safety protocols.

- Maintain a clean and organized work area to minimize risks.

- Report any safety concerns or incidents promptly to supervisors.

Interview Tips

To ace the interview for a C D Still Operator position, it’s crucial to prepare thoroughly and highlight your relevant skills and experience. Here are some tips and hacks to help you succeed:

1. Research the Company and Role

Before the interview, take the time to research the company you’re applying to and the specific role you’re seeking. This will help you understand the company’s culture, values, and the specific requirements of the position.

- Visit the company website to learn about their mission, products, and services.

- Review the job description carefully to identify the key responsibilities and qualifications.

2. Highlight Your Skills and Experience

In your interview, be sure to emphasize your relevant skills and experience that align with the job requirements. If you have experience operating C D Stills or similar equipment, be sure to mention it.

- Quantify your accomplishments whenever possible using specific metrics and results.

- Provide examples of your attention to detail, problem-solving abilities, and commitment to safety.

3. Demonstrate Safety Knowledge

As a C D Still Operator, you will be responsible for adhering to safety regulations and procedures. During the interview, make sure to highlight your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Be familiar with the relevant safety regulations and standards.

- Describe your experience in identifying and mitigating safety hazards.

- Emphasize your willingness to follow established safety guidelines and report any safety concerns.

4. Prepare Questions

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the position. Prepare a few questions that demonstrate your understanding of the role and the company.

- Ask about the company’s future goals and growth plans.

- Inquire about the training and development opportunities available for employees.

- Ask about the company’s commitment to environmental sustainability and safety.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the C D Still Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.