Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Causticiser position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

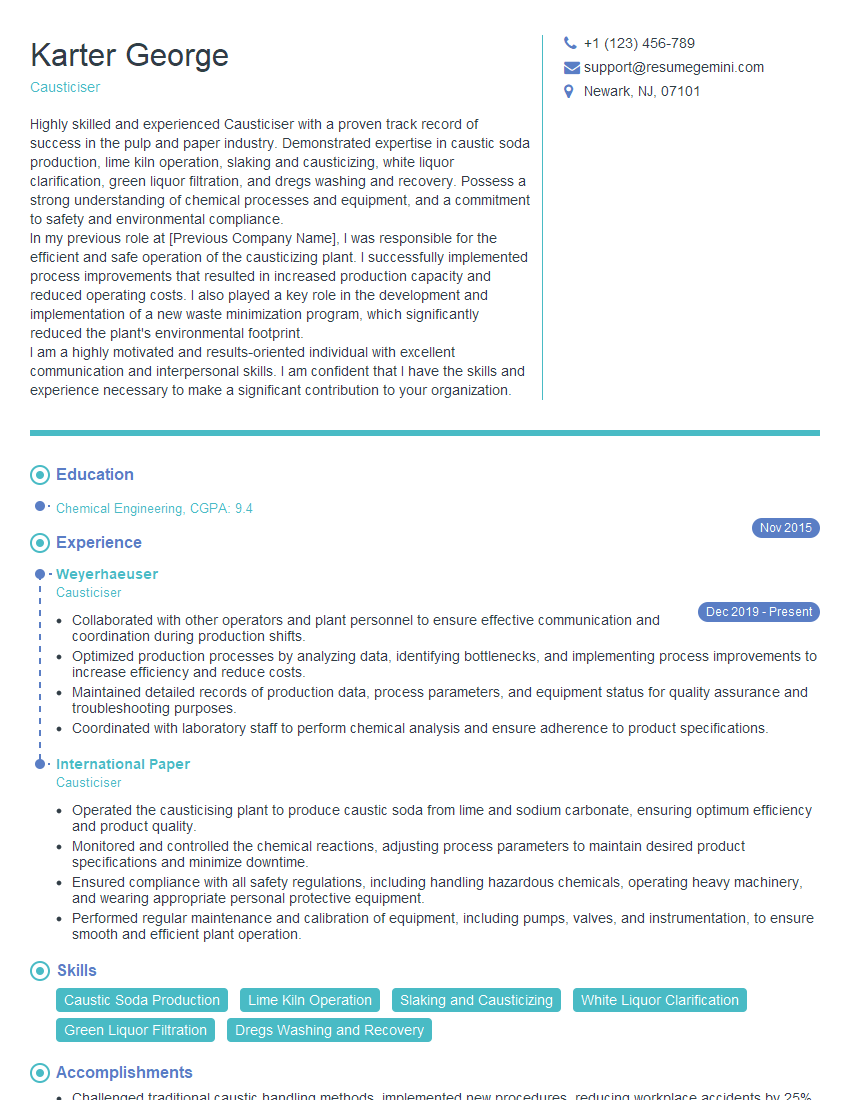

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Causticiser

1. Explain the process of causticisation in detail.

- Causticisation is a chemical process that converts sodium carbonate (soda ash) into sodium hydroxide (caustic soda).

- The process involves reacting soda ash with calcium hydroxide (lime) in a slaker, which produces calcium carbonate and caustic soda solution.

- The caustic soda solution is then clarified and concentrated in an evaporator to produce the final product.

2. What are the different types of causticization processes?

Lime-soda process

- The lime-soda process is the most common type of causticisation process.

- It involves reacting soda ash with calcium hydroxide in a slaker to produce calcium carbonate and caustic soda solution.

Electrolytic process

- The electrolytic process involves passing an electric current through a solution of sodium chloride to produce sodium hydroxide and chlorine gas.

- This process is more energy-intensive than the lime-soda process, but it produces a higher quality caustic soda product.

3. What are the key factors that affect the efficiency of a causticisation process?

- Temperature: The reaction between soda ash and lime is exothermic, so the temperature of the slaker must be carefully controlled to prevent the reaction from becoming too vigorous.

- Concentration: The concentration of soda ash and lime in the slaker must be carefully controlled to ensure that the reaction goes to completion.

- Residence time: The residence time of the reactants in the slaker must be sufficient to allow the reaction to go to completion.

4. What are the common problems that can occur during causticisation and how can they be solved?

- Scaling: Scaling can occur in the slaker, evaporator, and other equipment if the process conditions are not carefully controlled.

- Corrosion: Caustic soda is a corrosive substance, so the equipment used in the causticisation process must be made of corrosion-resistant materials.

- Foaming: Foaming can occur in the slaker and evaporator if the process conditions are not carefully controlled.

5. What are the safety precautions that must be taken when working with caustic soda?

- Caustic soda is a corrosive substance, so it is important to wear protective clothing, gloves, and eye protection when working with it.

- Caustic soda can also cause burns, so it is important to avoid contact with the skin.

- If caustic soda comes into contact with the skin, it should be washed off immediately with plenty of water.

6. What are the applications of caustic soda?

- Caustic soda is used in a wide variety of applications, including:

- The production of paper

- The production of soap and detergents

- The production of textiles

- The production of food

- The production of water treatment chemicals

7. What are the environmental impacts of caustic soda production?

- The production of caustic soda can have a number of environmental impacts, including:

- Air pollution: The production of caustic soda can release air pollutants, such as sulfur dioxide and nitrogen oxides, into the atmosphere.

- Water pollution: The production of caustic soda can release wastewater into the environment, which can contain pollutants such as sodium hydroxide, calcium carbonate, and chloride.

- Solid waste: The production of caustic soda can generate solid waste, such as slaker sludge and filter cake.

8. What are the future trends in caustic soda production?

- The future trends in caustic soda production include:

- The development of more energy-efficient and environmentally friendly caustic soda production processes.

- The use of renewable energy sources to power caustic soda production.

- The development of new applications for caustic soda.

9. What are the challenges facing the caustic soda industry?

- The caustic soda industry is facing a number of challenges, including:

- Increasing competition from low-cost producers.

- Rising energy costs.

- Environmental regulations.

10. What are the opportunities for the caustic soda industry?

- The caustic soda industry has a number of opportunities for growth, including:

- The growing demand for caustic soda in emerging markets.

- The development of new applications for caustic soda.

- The adoption of more energy-efficient and environmentally friendly caustic soda production processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Causticiser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Causticiser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Causticiser is responsible for overseeing the causticisation process, ensuring the production of high-quality caustic soda while adhering to safety and environmental regulations.

1. Process Management

Monitor and control the causticisation process, including lime slaking, milk of lime preparation, and causticisation reactions.

- Adjust process parameters (temperature, flow rates, pH) to optimise caustic soda production.

- Troubleshoot and resolve process deviations to maintain production efficiency.

2. Equipment Maintenance and Operation

Operate and maintain causticisation equipment, including lime slakers, milk of lime tanks, and causticisers.

- Perform preventive maintenance and repairs to ensure equipment reliability.

- Calibrate and maintain process instrumentation to ensure accurate readings.

3. Quality Control

Conduct quality control tests on caustic soda and other process materials.

- Monitor product quality parameters (concentration, purity) to meet customer specifications.

- Analyse process samples to identify and correct potential quality issues.

4. Safety and Environmental Compliance

Adhere to established safety protocols and environmental regulations.

- Follow standard operating procedures (SOPs) for handling hazardous chemicals.

- Monitor emissions and waste streams to ensure compliance with environmental standards.

Interview Tips

Preparing thoroughly for a Causticiser interview can significantly increase your chances of success. Here are some essential tips:

1. Research the Company and Position

Learn about the company’s history, products, and industry standing. Research the specific role and its responsibilities to demonstrate your understanding of the position.

2. Highlight Relevant Experience and Skills

Emphasise your experience in causticisation processes, chemical handling, and quality control. Showcase your ability to operate and maintain equipment and ensure product quality.

3. Prepare for Technical Questions

Expect questions related to causticisation chemistry, process control, and safety procedures. Study relevant concepts and practice answering technical questions clearly and confidently.

4. Practice Answering Behavioural Questions

Be ready to discuss your problem-solving abilities, teamwork experience, and commitment to safety. Use the STAR method to provide specific examples from your past experiences.

5. Ask Insightful Questions

Asking thoughtful questions during the interview shows your interest and engagement. Inquire about the company’s growth plans, sustainability initiatives, or opportunities for professional development.

Next Step:

Now that you’re armed with the knowledge of Causticiser interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Causticiser positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini