Are you gearing up for an interview for a Dehydrogenation Converter Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Dehydrogenation Converter Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

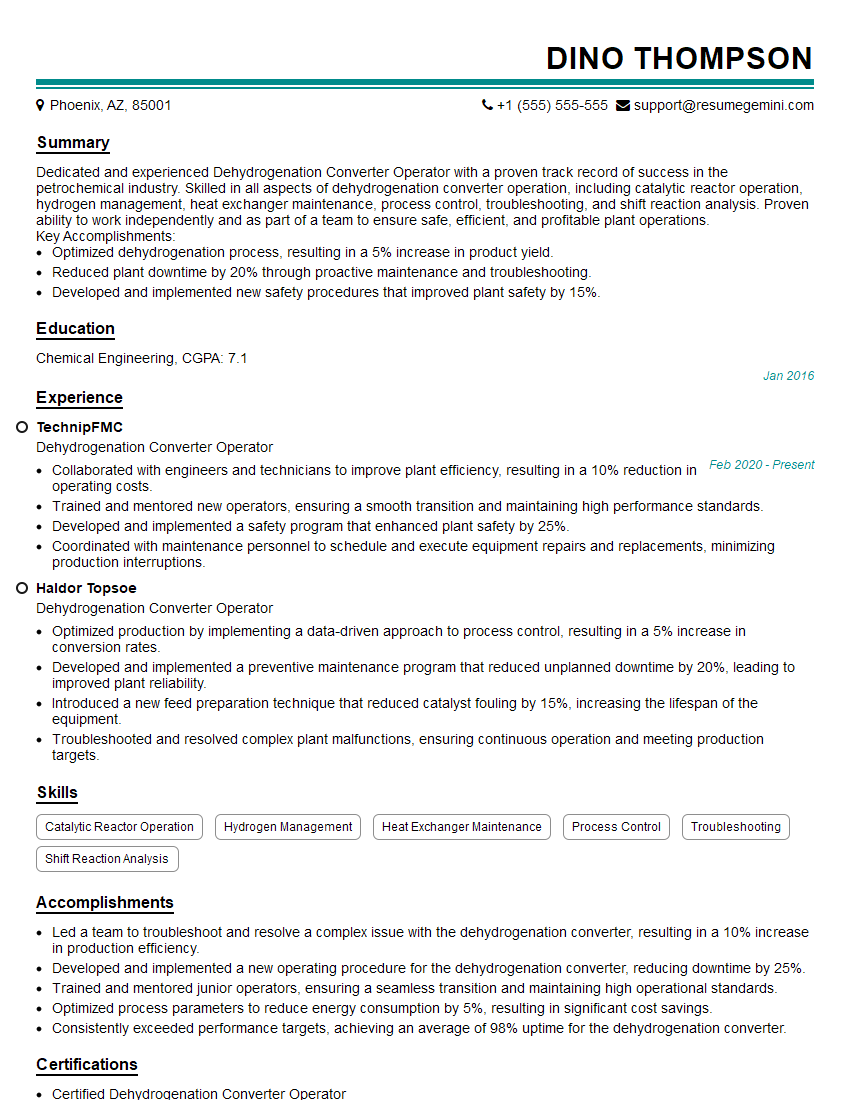

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dehydrogenation Converter Operator

1. Describe the process of dehydrogenation conversion in a petrochemical plant.

The dehydrogenation conversion process in a petrochemical plant involves the removal of hydrogen from a hydrocarbon feedstock to produce a more unsaturated product. This process is typically carried out in a reactor vessel under high temperatures and in the presence of a catalyst. The feedstock is heated to a high temperature, and the catalyst promotes the removal of hydrogen from the hydrocarbon molecules. The resulting product is then cooled and separated from the catalyst.

2. What are the key operating parameters that must be controlled in a dehydrogenation converter?

Temperature

- The temperature of the reactor is a critical parameter that must be controlled to ensure the desired conversion rate and product selectivity.

- Too high of a temperature can lead to the formation of unwanted byproducts, while too low of a temperature will result in a lower conversion rate.

Pressure

- The pressure of the reactor is also an important parameter that must be controlled, as it can affect the equilibrium of the reaction.

- Too high of a pressure can result in the formation of unwanted byproducts, while too low of a pressure will result in a lower conversion rate.

Feedstock composition

- The composition of the feedstock can also affect the performance of the dehydrogenation converter.

- The presence of impurities in the feedstock can lead to the formation of unwanted byproducts, and the concentration of the reactant in the feedstock can affect the conversion rate.

3. What are the common troubleshooting procedures for a dehydrogenation converter that is not operating properly?

- Check the temperature and pressure of the reactor to ensure that they are within the desired operating range.

- Check the feedstock composition to ensure that it is free of impurities and that the concentration of the reactant is correct.

- Check the catalyst to ensure that it is active and that it is not contaminated.

- Check the equipment for any leaks or other mechanical problems.

4. What are the safety precautions that must be taken when operating a dehydrogenation converter?

- The dehydrogenation converter should be operated in a well-ventilated area, as the process can release hazardous gases.

- The reactor should be equipped with a pressure relief valve to prevent over-pressurization.

- The equipment should be inspected regularly for any leaks or other mechanical problems.

- Operators should wear appropriate personal protective equipment, such as gloves, safety glasses, and a respirator.

5. What are the different types of dehydrogenation converters that are used in the petrochemical industry?

- Fixed-bed dehydrogenation converters

- Fluidized-bed dehydrogenation converters

- Shell-and-tube dehydrogenation converters

6. What are the advantages and disadvantages of using a fixed-bed dehydrogenation converter?

Advantages

- Fixed-bed dehydrogenation converters are relatively simple to design and operate.

- They can be used to produce a wide range of products.

- They are relatively inexpensive to build and maintain.

Disadvantages

- Fixed-bed dehydrogenation converters can be prone to fouling and deactivation.

- They can be difficult to control, and they can be subject to thermal runaway.

7. What are the advantages and disadvantages of using a fluidized-bed dehydrogenation converter?

Advantages

- Fluidized-bed dehydrogenation converters are less prone to fouling and deactivation than fixed-bed dehydrogenation converters.

- They are easier to control, and they are less subject to thermal runaway.

- They can be used to produce a wider range of products than fixed-bed dehydrogenation converters.

Disadvantages

- Fluidized-bed dehydrogenation converters are more expensive to build and maintain than fixed-bed dehydrogenation converters.

- They can be more difficult to operate, and they can be more subject to attrition.

8. What are the advantages and disadvantages of using a shell-and-tube dehydrogenation converter?

Advantages

- Shell-and-tube dehydrogenation converters are relatively simple to design and operate.

- They are relatively inexpensive to build and maintain.

- They are less prone to fouling and deactivation than fixed-bed and fluidized-bed dehydrogenation converters.

Disadvantages

- Shell-and-tube dehydrogenation converters are less efficient than fixed-bed and fluidized-bed dehydrogenation converters.

- They can be more difficult to control, and they can be more subject to thermal runaway.

9. What are the key performance indicators for a dehydrogenation converter?

- Conversion rate

- Product selectivity

- Energy efficiency

- Reliability

- Maintainability

10. What are the future trends in dehydrogenation converter technology?

- The development of more efficient and selective catalysts

- The use of new reactor designs to improve conversion rates and product selectivity

- The integration of dehydrogenation converters with other process units to improve overall plant efficiency

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dehydrogenation Converter Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dehydrogenation Converter Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

## Key Job Responsibilities A Dehydrogenation Converter Operator is responsible for the safe and efficient operation of a dehydrogenation converter unit, which involves converting hydrocarbons into olefins. Key responsibilities include:intro paragraph

1. Operation and Monitoring

intro paragraph

- Monitor and control the dehydrogenation process to ensure optimal production rates and product quality.

- Operate and maintain the process equipment, including reactors, furnaces, and compressors.

2. Safety and Compliance

intro paragraph

- Follow all safety protocols and regulations related to the operation of the dehydrogenation unit.

- Identify and mitigate potential safety hazards, ensuring a safe working environment.

3. Troubleshooting and Maintenance

intro paragraph

- Troubleshoot and resolve process malfunctions or equipment failures to maintain continuous operation.

- Perform routine maintenance and inspections of the unit to ensure its integrity and reliability.

4. Data Collection and Reporting

intro paragraph

- Record and analyze process data to identify areas for improvement and optimize performance.

- Provide timely and accurate reports on the unit’s operation to management and other stakeholders.

intro paragraph

1. Research the Company and Position

intro paragraph

- Familiarize yourself with the company’s operations, their dehydrogenation unit, and the specific requirements of the position.

- Research the industry and keep up-to-date with current trends and advancements in dehydrogenation technology.

2. Highlight Relevant Experience and Skills

intro paragraph

- Emphasize your experience in operating and maintaining dehydrogenation or similar process units.

- Describe your troubleshooting, maintenance, and data analysis capabilities.

3. Demonstrate Safety Knowledge

intro paragraph

- Clearly convey your understanding of safety protocols and regulations related to dehydrogenation operations.

- Provide examples of how you have identified and mitigated safety hazards in previous roles.

4. Prepare for Technical Questions

intro paragraph

- Review the basics of dehydrogenation chemistry and process technology.

- Be ready to discuss troubleshooting techniques for common problems encountered in dehydrogenation operations.

5. Show Enthusiasm and Motivation

intro paragraph

- Convey your passion for the chemical industry and your interest in the dehydrogenation process.

- Explain how you can contribute to the success of the company’s dehydrogenation unit.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Dehydrogenation Converter Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.