Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fermenter Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

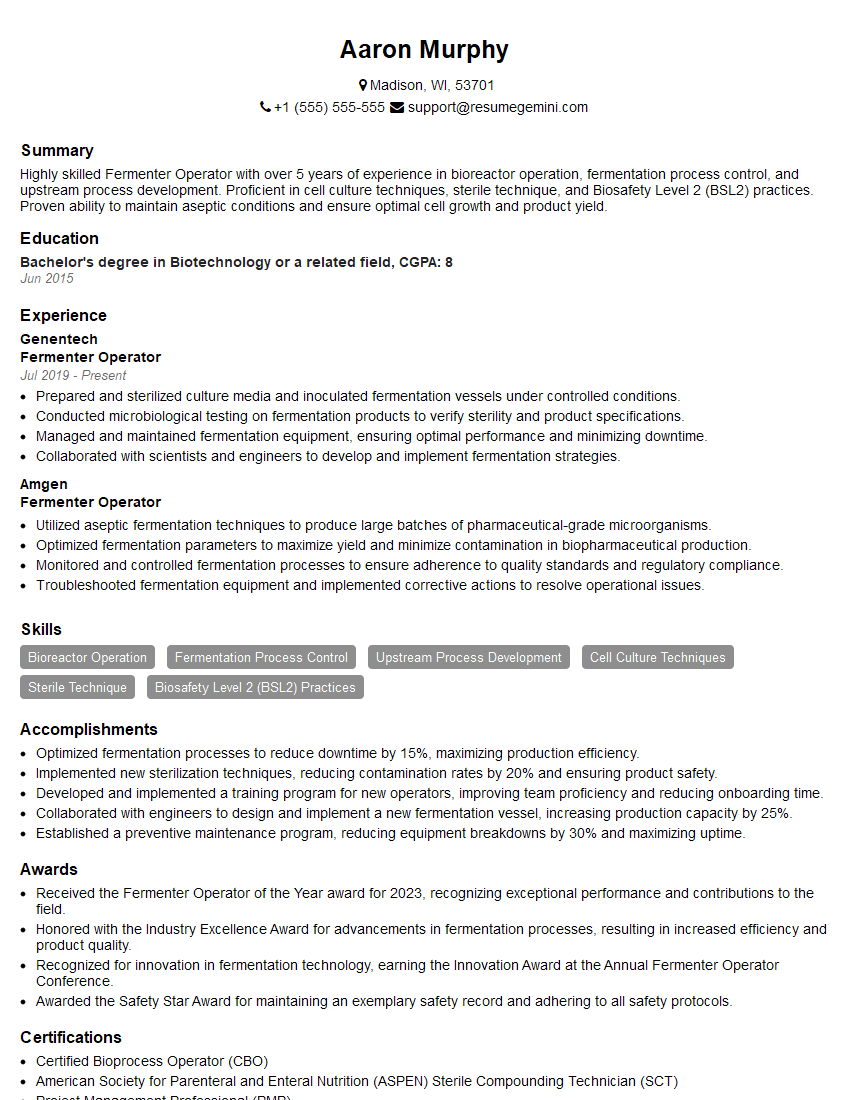

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fermenter Operator

1. Explain the key responsibilities of a Fermenter Operator?

- Monitoring and controlling the fermentation process to ensure optimal conditions for microbial growth and product formation.

- Sampling and testing fermentation broth to monitor cell growth, substrate utilization, and product yield.

- Maintaining sterile conditions within the fermenter to prevent contamination.

- Performing routine maintenance and troubleshooting on fermentation equipment.

- Following established protocols and adhering to safety regulations.

2. Describe the different types of fermentation processes and their applications?

- Involves growing microorganisms in a closed system with limited nutrient supply.

- Used for producing antibiotics, enzymes, and other secondary metabolites.

- Nutrients are continuously added to the fermenter during the fermentation process.

- Used for producing high cell densities, such as for biofuel production.

- Fresh media is continuously fed into the fermenter, while fermented broth is continuously removed.

- Used for producing large volumes of products, such as ethanol and organic acids.

Batch Fermentation

Fed-batch Fermentation

Continuous Fermentation

3. Discuss the factors that affect microbial growth and metabolism in a fermentation process?

- Temperature

- pH

- Oxygen concentration

- Substrate availability

- Presence of inhibitors

4. Explain the principles of aseptic techniques and their importance in fermentation processes?

- Aseptic techniques prevent the introduction of microorganisms into a sterile environment.

- They involve using sterilized equipment, maintaining a sterile environment, and following proper procedures for handling and transferring materials.

- Aseptic techniques are essential for preventing contamination and ensuring the production of high-quality products.

5. Describe the different types of fermenters and their applications?

- Uses mechanical agitation to mix the fermentation broth.

- Suitable for a wide range of fermentation processes.

- Uses aeration to mix the fermentation broth.

- Suitable for processes requiring high oxygen transfer rates.

- Gas bubbles flow upward through the fermentation broth, creating agitation.

- Suitable for processes involving large volumes of liquid.

Stirred Tank Fermenter

Airlift Fermenter

Tower Fermenter

6. Explain the role of sensors and control systems in fermentation processes?

- Sensors monitor critical parameters such as temperature, pH, and oxygen concentration.

- Control systems use sensor data to adjust conditions within the fermenter to maintain optimal levels.

- Automation of fermentation processes helps ensure consistency, efficiency, and product quality.

7. Discuss the importance of scale-up in fermentation processes?

- Scale-up involves transferring fermentation processes from small-scale laboratory experiments to larger-scale production facilities.

- It requires careful consideration of factors such as mass transfer, heat transfer, and mixing.

- Successful scale-up ensures efficient production and consistent product quality.

8. Explain the regulatory requirements for fermentation processes?

- Fermentation processes must comply with regulations governing the production of food, pharmaceuticals, and other products.

- Regulatory requirements cover aspects such as good manufacturing practices (GMP), environmental protection, and product safety.

- Familiarity with regulatory requirements is essential for ensuring compliance and maintaining product quality.

9. Describe the troubleshooting steps for common problems encountered in fermentation processes?

- Identify the problem by observing symptoms and analyzing data.

- Trace the problem back to its root cause by considering possible factors such as equipment failure, contamination, or process deviations.

- Develop and implement corrective actions to resolve the problem and prevent recurrence.

- Document troubleshooting steps and actions taken for future reference.

10. Explain the importance of teamwork and communication in fermentation operations?

- Teamwork is essential for coordinating tasks, sharing knowledge, and solving problems.

- Effective communication ensures timely information sharing, clear instructions, and efficient decision-making.

- Collaboration among team members promotes a positive work environment and contributes to overall success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fermenter Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fermenter Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fermenter Operators play a crucial role in the biotechnology and pharmaceutical industries, ensuring the safe and efficient operation of fermentation processes. They are responsible for monitoring and controlling various parameters, maintaining sterile environments, and conducting sampling and analysis to ensure product quality and yield.

1. Process Monitoring and Control

Monitor and control fermentation parameters such as temperature, pH, dissolved oxygen, and agitation to optimize growth conditions.

2. Sterile Environment Maintenance

Adhere to strict aseptic techniques to prevent contamination of the fermentation process and ensure product quality.

3. Sampling and Analysis

Collect and analyze samples to monitor cell growth, metabolite production, and potential contaminants.

4. Equipment Maintenance

Perform routine maintenance and calibration of fermentation equipment, including bioreactors, pumps, and sensors.

Interview Tips

To ace the interview for a Fermenter Operator position, candidates should prepare thoroughly and showcase their skills and experience in the following areas:

1. Technical Knowledge

Demonstrate a strong understanding of fermentation processes, including aseptic techniques, process control, and quality assurance.

2. Attention to Detail

Emphasize your ability to monitor and record data accurately, identify deviations, and take corrective actions promptly.

3. Problem-Solving Skills

Highlight your ability to troubleshoot equipment issues, identify potential problems, and develop solutions to maintain process efficiency.

4. Teamwork and Communication

Explain your experience working in a team environment, collaborating with colleagues, and communicating effectively with supervisors.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Fermenter Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Fermenter Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.