Feeling lost in a sea of interview questions? Landed that dream interview for MVA Still Operator (Monovinylacetylene Still Operator) but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common MVA Still Operator (Monovinylacetylene Still Operator) interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

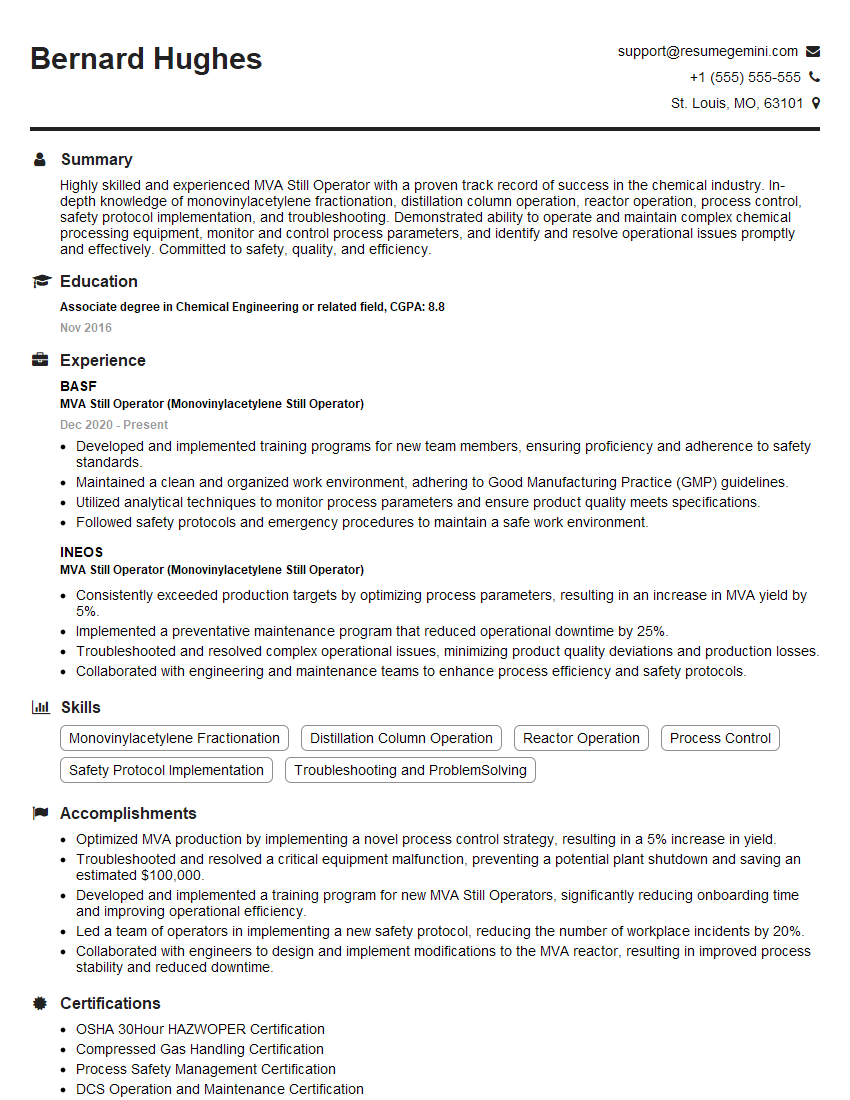

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For MVA Still Operator (Monovinylacetylene Still Operator)

1. What is the role of a MVA Still Operator?

The primary role of an MVA Still Operator is to operate and maintain a Monovinylacetylene (MVA) still. This involves:

- Monitoring and controlling the distillation process

- Ensuring the quality of the MVA product

- Maintaining and troubleshooting the still equipment

- Following safety protocols and procedures

2. Describe the distillation process used in MVA production.

Batch Distillation

- Involves filling the still with a mixture of MVA and water

- Heating the mixture until the MVA vaporizes

- Collecting the MVA vapor and condensing it into a liquid

Continuous Distillation

- Uses a continuous feed of MVA and water into the still

- Separates the MVA vapor from the water vapor using a series of trays or columns

- Results in a continuous flow of purified MVA

3. How do you ensure the quality of the MVA product?

To ensure MVA product quality, I perform the following tasks:

- Monitor the distillation temperature and pressure

- Collect samples and analyze their purity using gas chromatography

- Make adjustments to the distillation process as needed

- Maintain detailed records of all quality control measures

4. What are the common maintenance tasks required for an MVA still?

Regular maintenance tasks for an MVA still include:

- Cleaning and inspecting the still, condenser, and piping

- Replacing worn or damaged parts

- Lubricating moving components

- Calibrating instruments and sensors

- Performing preventive maintenance as per the manufacturer’s recommendations

5. How do you troubleshoot operational issues in an MVA still?

When troubleshooting operational issues, I follow a systematic approach:

- Identify the problem and its symptoms

- Review process data and operating parameters

- Conduct visual inspections and tests

- Consult with colleagues and technical experts

- Implement corrective actions and monitor their effectiveness

6. What safety protocols are essential for operating an MVA still?

Essential safety protocols for operating an MVA still include:

- Wearing appropriate personal protective equipment

- Following lockout/tagout procedures

- Handling flammable materials with care

- Monitoring for leaks and spills

- Responding to emergencies in a timely and appropriate manner

7. What is the impact of temperature and pressure on the MVA distillation process?

Temperature and pressure play crucial roles in MVA distillation:

Temperature

- Higher temperatures increase the vapor pressure of MVA

- Optimizing temperature ensures efficient separation of MVA from water

Pressure

- Lower pressures reduce the boiling point of MVA

- Controlling pressure helps maintain product quality and prevent thermal degradation

8. How do you optimize the MVA distillation process for maximum yield?

To optimize the MVA distillation process for maximum yield, I focus on the following:

- Maintaining optimal temperature and pressure conditions

- Using high-quality raw materials

- Minimizing losses during distillation and handling

- Regularly calibrating instruments and monitoring process parameters

- Implementing preventive maintenance to ensure equipment efficiency

9. What are the key performance indicators (KPIs) used to measure the effectiveness of an MVA still operator?

KPIs commonly used to measure the effectiveness of an MVA still operator include:

- MVA product yield and purity

- Still uptime and efficiency

- Process cycle time and throughput

- Compliance with safety protocols and regulations

- Cost of production and energy consumption

10. How do you stay updated with the latest advancements in MVA still technology and best practices?

To stay updated, I engage in the following activities:

- Attending industry conferences and workshops

- Reading technical journals and research papers

- Participating in online forums and discussions

- Consulting with experts in the field

- Seeking opportunities for professional development and training

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for MVA Still Operator (Monovinylacetylene Still Operator).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the MVA Still Operator (Monovinylacetylene Still Operator)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The MVA Still Operator is responsible for the safe and efficient operation of the Monovinylacetylene (MVA) still. This includes:

1. Starting up and shutting down the still

The operator must follow established procedures to start up and shut down the still safely. This includes checking the equipment, setting the correct operating parameters, and monitoring the still during operation.

2. Monitoring the still’s operation

The operator must constantly monitor the still’s operation to ensure that it is running safely and efficiently. This includes checking the temperature, pressure, and flow rate of the reactants and products, and making adjustments as needed.

3. Troubleshooting and resolving problems

The operator must be able to troubleshoot and resolve problems that may occur during the operation of the still. This includes identifying the root cause of the problem and taking steps to correct it.

4. Maintaining the still

The operator is responsible for maintaining the still in good working order. This includes cleaning the still, replacing worn parts, and making repairs as needed.

5. Training new operators

The operator may be responsible for training new operators on the safe and efficient operation of the still.

Interview Tips

Preparing for an interview for an MVA Still Operator position can be daunting, but with the right preparation, you can increase your chances of success.

1. Research the company and the position

Before you go to your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, and will also give you a better understanding of the role you would be playing in the organization.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Take some time to practice answering these questions in a clear and concise way.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience and how it qualifies you for the position. Be prepared to talk about your experience in operating and maintaining chemical processing equipment, as well as your experience in troubleshooting and resolving problems.

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you are respectful of their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the MVA Still Operator (Monovinylacetylene Still Operator) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!