Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Poly Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Poly Operator so you can tailor your answers to impress potential employers.

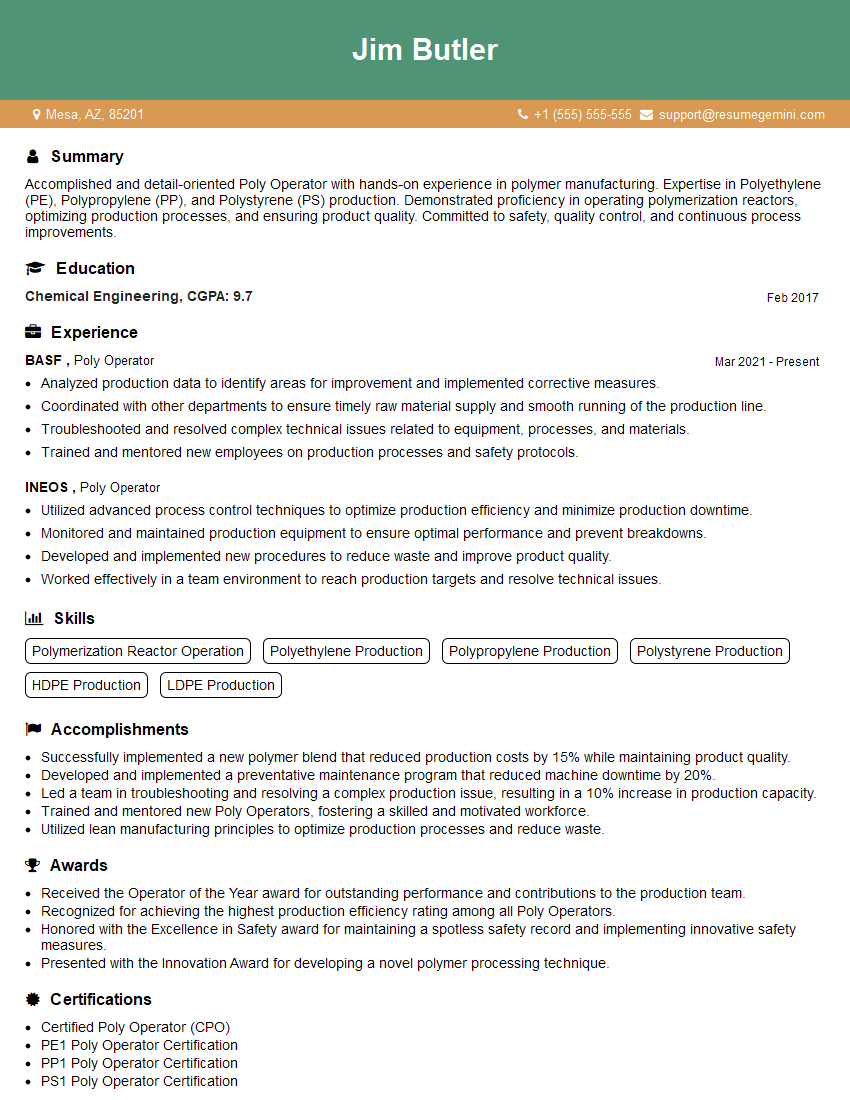

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Poly Operator

1. Explain the process of preparing a poly master batch?

- The process involves measuring and mixing different types of polymers, such as polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC), in specific proportions.

- The mixture is then heated and extruded into a molten state, creating a homogeneous blend.

- Additives, such as colorants, stabilizers, and fillers, may be added to enhance the properties of the master batch.

- The molten blend is then cooled and pelletized into small, uniform granules.

2. Describe the different types of extrusion processes used in poly production?

Blown film extrusion

- Involves extruding molten polymer through a circular die to create a tubular film.

- The film is then inflated with air to expand and create a thin, flexible sheet.

Cast film extrusion

- Molten polymer is extruded through a flat die onto a chilled roller.

- The polymer solidifies as it cools on the roller, creating a smooth, glossy film.

Injection molding

- Molten polymer is injected into a mold cavity under high pressure.

- The polymer solidifies and takes the shape of the mold, creating a variety of complex parts.

3. What are the key parameters to control in the extrusion process to ensure product quality?

- Extruder temperature: Maintaining optimal temperature ensures proper polymer flow and melt homogeneity.

- Screw speed: Adjusting the screw speed controls the polymer residence time in the extruder, affecting melt properties.

- Die and mold design: The design of the die and mold influences the shape and dimensions of the extruded product.

- Cooling rate: Controlling the cooling rate affects the crystallization and mechanical properties of the polymer.

4. Explain the role of additives in poly production?

- Colorants: Add color to the polymer for aesthetic purposes.

- Stabilizers: Protect the polymer from degradation caused by heat, light, and oxygen.

- Fillers: Enhance the physical properties of the polymer, such as strength, stiffness, and thermal resistance.

- Antioxidants: Prevent premature aging and degradation of the polymer.

- Lubricants: Reduce friction during processing and improve surface smoothness.

5. Describe the quality control measures implemented in poly production?

- Raw material inspection: Ensuring the quality and consistency of incoming polymers.

- Process monitoring: Continuously monitoring key parameters during extrusion to maintain process stability.

- Product testing: Conducting physical, chemical, and mechanical tests on finished products to meet specifications.

- Documentation and traceability: Maintaining accurate records of production parameters and product test results for quality assurance.

6. What is the difference between polyethylene and polypropylene?

Polyethylene (PE)

- Highly flexible and impact-resistant.

- Low density and good chemical resistance.

- Applications: Plastic bags, films, bottles, toys.

Polypropylene (PP)

- Rigid and strong.

- Higher melting point and resistance to heat and chemicals.

- Applications: Automotive parts, containers, appliances.

7. Explain the concept of polymer blending?

- Combining different polymers to create materials with tailored properties.

- Enhances strength, toughness, flexibility, and other characteristics.

- Allows for the optimization of polymer properties for specific applications.

8. What are the challenges and opportunities in the poly industry?

Challenges

- Fluctuating raw material prices.

- Environmental concerns related to plastic waste.

- Increasing competition from alternative materials.

Opportunities

- Growing demand for lightweight and durable materials.

- Advancements in polymer science and technology.

- Development of biodegradable and sustainable polymers.

9. Describe your experience in troubleshooting extrusion problems?

- Identifying the source of the problem, such as equipment malfunction, improper parameter settings, or raw material issues.

- Analyzing the process data and making necessary adjustments to resolve the problem.

- Implementing corrective actions to prevent the problem from recurring.

10. How do you stay updated with the latest developments in the poly industry?

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Networking with professionals in the field.

- Participating in online forums and discussion groups.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Poly Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Poly Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Poly Operator, you will play a vital role in the production process, ensuring the smooth and efficient manufacturing of polymer products.

1. Polymer Processing

Your primary responsibility will be operating and monitoring polymerization reactors to produce polymers such as polyethylene and polypropylene.

- Control process parameters to optimize production yield and quality

- Monitor and adjust equipment to maintain stable operating conditions

2. Equipment Maintenance

You will be responsible for performing routine maintenance and troubleshooting of production equipment.

- Conduct preventive maintenance tasks to ensure equipment reliability

- Diagnose and resolve equipment malfunctions promptly

3. Process Monitoring

You will continuously monitor the production process to ensure quality and safety.

- Monitor process variables, such as temperature, pressure, and flow rates

- Inspect polymers for defects and non-conformities

4. Safety and Compliance

You will be responsible for adhering to all safety regulations and operating procedures.

- Follow established safety protocols and wear appropriate protective gear

- Maintain a clean and organized work environment

Interview Preparation Tips

Here are some interview preparation tips to help you ace your interview as a Poly Operator:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and market position. Learn about the polymer industry and its trends.

2. Practice Answering Common Interview Questions

Prepare answers to common interview questions related to your experience, skills, and qualifications. Consider using the STAR method to structure your responses.

### Example Outline:Situation: Describe a challenging situation you faced in a previous role as a Poly Operator.

Task: Explain the specific task or action you took to resolve the situation.

Action: Describe the steps you followed to implement the solution.

Result: Quantify the positive outcomes or impact of your actions.

3. Highlight Your Technical Skills

Emphasize your proficiency in polymer processing technologies, equipment operation, and maintenance. Share examples of how you have used these skills to improve efficiency or solve problems.

4. Demonstrate Safety Consciousness

Stress your commitment to safety and compliance in the workplace. Highlight your knowledge of industry regulations and your experience in implementing safety protocols.

5. Show Your Passion for the Industry

Express your interest in the polymer industry and your desire to contribute to its advancement. Share any examples of your involvement in industry events or research projects.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Poly Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!