Feeling lost in a sea of interview questions? Landed that dream interview for Viscose Cellar Worker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Viscose Cellar Worker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

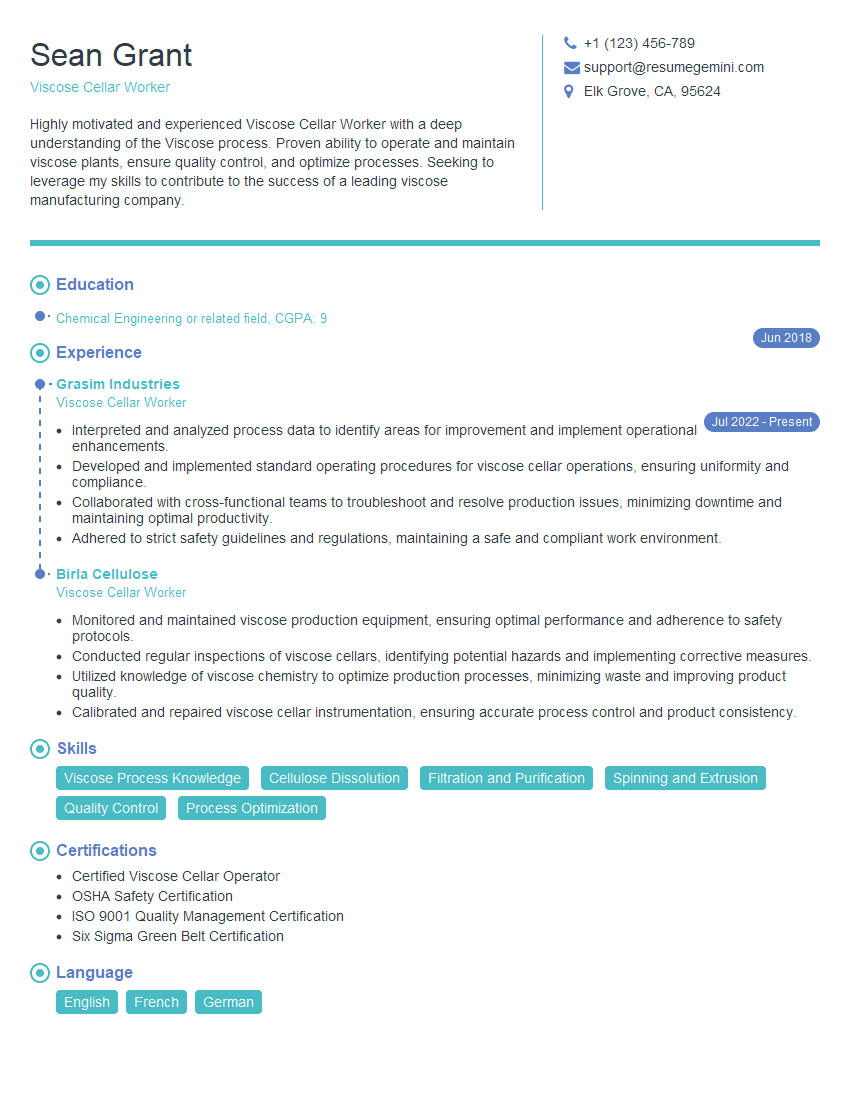

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Viscose Cellar Worker

1. Describe the process of preparing a viscose cellar for operation.

- Inspect the cellar for any damage or leaks.

- Clean the cellar thoroughly, removing any debris or contaminants.

- Set up the necessary equipment, including pumps, mixers, and filters.

- Calibrate the equipment and ensure it is functioning properly.

- Prepare the viscose solution by adding the appropriate chemicals and solvents.

2. What are the key parameters that need to be monitored and controlled during the viscose ripening process?

Temperature

- Temperature should be maintained within a narrow range to ensure proper ripening.

- Temperature fluctuations can lead to defects in the final product.

pH

- pH must be controlled to prevent the formation of precipitates and ensure proper viscose flow.

- pH can be adjusted by adding acid or alkali.

Viscosity

- Viscosity should be monitored to ensure the viscose solution is of the correct consistency.

- Viscosity can be adjusted by adding water or solvents.

Maturity

- Maturity is a measure of the viscose solution’s readiness for spinning.

- Maturity can be determined by testing the solution’s viscosity and pH.

3. How do you handle and resolve unexpected changes in the viscose ripening process?

- Identify the source of the change and determine the cause.

- Adjust the process parameters (temperature, pH, etc.) as necessary to bring the solution back within specification.

- Monitor the solution closely and make further adjustments as needed.

- If the problem cannot be resolved, notify the supervisor or other relevant personnel.

4. Describe the different types of filtration systems used in the viscose cellar.

Pressure Filters

: Force the viscose solution through a filter media using pressure.Suction Filters

: Use a vacuum to draw the viscose solution through a filter media.Gravity Filters

: Allow the viscose solution to flow through a filter media under the force of gravity.Electrostatic Filters

: Use an electrostatic charge to attract and remove contaminants from the viscose solution.

5. How do you ensure the quality of the viscose solution before it is sent for spinning?

- Test the solution for maturity, viscosity, and pH.

- Inspect the solution for any visible impurities or defects.

- Filter the solution to remove any remaining contaminants.

- Sample and approve the solution before releasing it for spinning.

6. Describe the safety precautions that must be taken when working in a viscose cellar.

- Wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a respirator.

- Be aware of the potential for exposure to hazardous chemicals.

- Follow all safety procedures and protocols.

- Report any accidents or incidents immediately.

7. What are the different types of spinning processes used in the production of viscose fibers?

Wet Spinning

: The viscose solution is extruded into a coagulating bath, where it forms solid fibers.Dry Spinning

: The viscose solution is extruded into a hot gas, where it dries and forms solid fibers.Melt Spinning

: The viscose solution is heated until it melts, then extruded and cooled to form solid fibers.

8. How do you optimize the spinning process to produce high-quality viscose fibers?

- Control the temperature, pH, and viscosity of the viscose solution.

- Set the spinning machine parameters (spinneret size, extrusion rate, etc.) correctly.

- Monitor the spinning process and make adjustments as needed.

- Inspect the fibers for quality and make adjustments to the process accordingly.

9. Describe the different post-spinning treatments that can be applied to viscose fibers to enhance their properties.

Drawing

: Stretches the fibers to increase their strength and orientation.Annealing

: Heats the fibers to relieve stress and improve their durability.Bleaching

: Whitens the fibers and removes impurities.Dyeing

: Adds color to the fibers.Finishing

: Applies various treatments to improve the fibers’ appearance, texture, and performance.

10. What are the challenges and opportunities for the viscose industry in the future?

Challenges

- Competition from other synthetic and natural fibers.

- Environmental regulations and sustainability concerns.

- Fluctuating raw material prices.

Opportunities

- Growing demand for sustainable and eco-friendly fibers.

- Advances in viscose production technology and innovation.

- Increased use of viscose fibers in new and emerging applications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Viscose Cellar Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Viscose Cellar Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Viscose Cellar Worker is responsible for overseeing the various stages of viscose production, ensuring the smooth functioning of the plant and maintaining high quality standards. Their primary duties include:

1. Viscose Preparation

• Preparing and mixing the raw materials for viscose production

- Weighing and measuring ingredients according to specified ratios

- Operating blending and mixing equipment to create a uniform mixture

2. Xanthation Process

• Supervising the chemical reaction known as xanthation

- Monitoring temperature, pressure, and other parameters during the reaction

- Ensuring the formation of cellulose xanthate, the intermediate product

3. Spinning and Coagulation

• Operating spinning machines to produce viscose filaments

- Setting up and adjusting spinnerets to control fiber properties

- Monitoring the coagulation process to form solid viscose fibers

4. Washing and Drying

• Thoroughly washing the viscose fibers to remove impurities

- Operating washing machines and dryers to remove excess chemicals and water

- Ensuring the fibers meet the desired moisture content and quality standards

5. Quality Assurance

• Conducting regular quality checks throughout the production process

- Testing fiber properties, such as strength, elasticity, and fineness

- Identifying and troubleshooting any deviations from specifications

6. Maintenance and Repair

• Performing routine maintenance and repairs on equipment

- Cleaning and lubricating machinery to prevent breakdowns

- Working with mechanics and engineers to resolve complex issues

7. Safety and Compliance

• Adhering to safety protocols and industry regulations

- Wearing protective gear and following proper handling procedures

- Maintaining a clean and organized work environment

Interview Tips

To ace an interview for a Viscose Cellar Worker position, candidates should prepare thoroughly by researching the industry, practicing their answers, and showcasing their relevant skills and experience.

1. Research the Company and Industry

• Visit the company’s website to learn about their products, services, and culture

• Research the viscose production industry to understand the latest trends and technologies

2. Practice Your Answers

• Prepare for common interview questions related to your skills, experience, and knowledge of the industry

• Practice answering questions confidently and concisely, highlighting your most relevant qualifications

3. Highlight Your Skills and Experience

• Emphasize your technical skills related to viscose production, including xanthation, spinning, and fiber processing

• Showcase your experience in maintaining and repairing equipment, as well as your knowledge of safety protocols

4. Demonstrate Your Problem-Solving Abilities

• Provide examples of how you have identified and resolved issues in a work environment

• Explain how you would approach potential challenges in the viscose production process

5. Ask Thoughtful Questions

• During the interview, ask insightful questions that demonstrate your interest in the company and the position

• Inquire about the company’s growth plans, sustainability initiatives, or any opportunities for professional development

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Viscose Cellar Worker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Viscose Cellar Worker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.