Are you gearing up for a career in Viscose Cellar Charge Hand? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Viscose Cellar Charge Hand and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

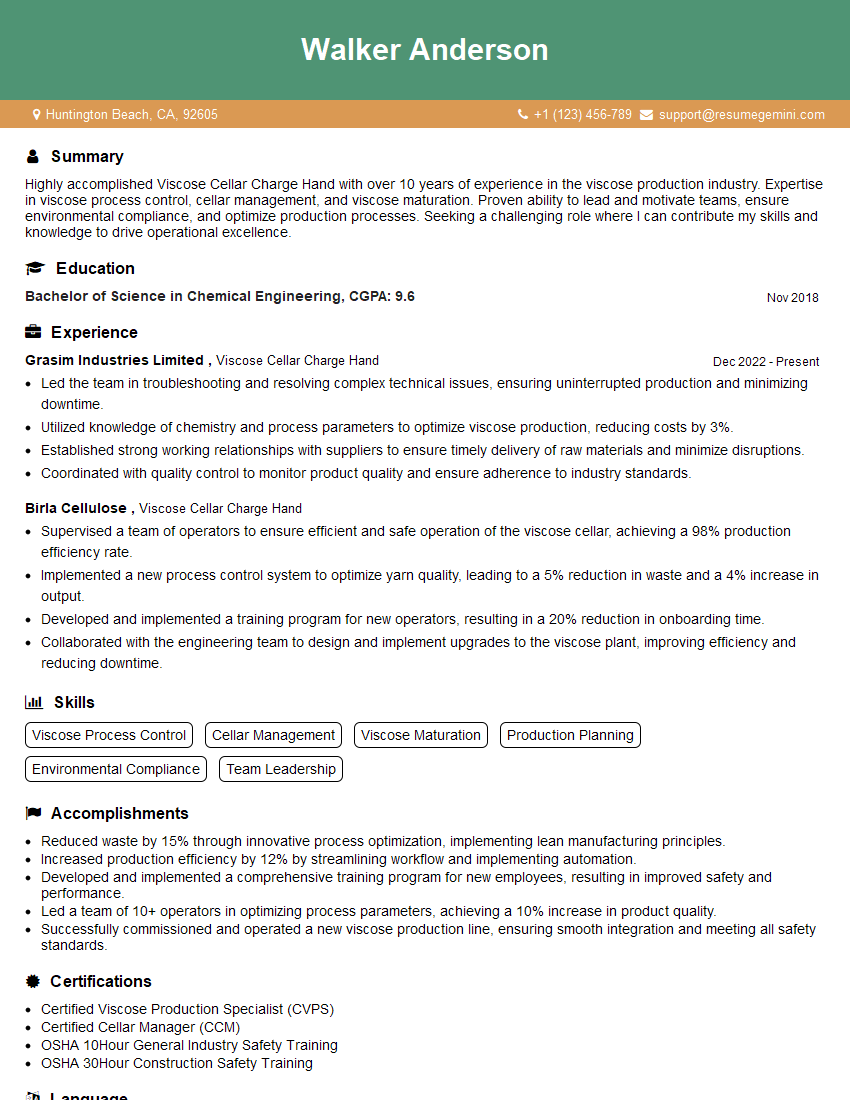

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Viscose Cellar Charge Hand

1. Explain the process of viscose production?

The viscose production process involves several stages:

- Preparation of wood pulp: Cellulose fibers are extracted from wood pulp through mechanical and chemical processes.

- Steeping: The wood pulp is treated with sodium hydroxide to form alkali cellulose.

- Pressing: The alkali cellulose is pressed to remove excess liquid.

- Aging: The pressed alkali cellulose is aged to enhance its solubility and reduce its reactivity.

- Xanthation: The aged alkali cellulose is treated with carbon disulfide to form sodium cellulose xanthate, which is soluble in water.

- Dissolving: The sodium cellulose xanthate is dissolved in water to form a viscous liquid known as viscose.

- Spinning: The viscose solution is extruded through spinnerets into a coagulating bath, which solidifies the fibers into viscose yarn or film.

2. What are the key responsibilities of a Viscose Cellar Charge Hand?

- Supervise and coordinate the operations of the viscose cellar, ensuring efficient and safe production of viscose solution.

- Monitor the quality of raw materials and finished products, adherence to production parameters, and compliance with safety regulations.

- Maintain and calibrate equipment, troubleshoot issues, and implement corrective actions to optimize production.

- Train and provide guidance to operators and ensure adherence to standard operating procedures.

- Collaborate with other departments and external stakeholders to ensure smooth production processes.

3. Describe the importance of controlling the viscosity of viscose solution?

Controlling the viscosity of viscose solution is crucial for several reasons:

- Spinnability: The viscosity determines the spinnability of the viscose solution, affecting the quality and properties of the resulting yarn or film.

- Fiber properties: Viscosity influences the strength, elasticity, and other physical properties of the viscose fibers.

- Processability: Proper viscosity ensures optimal flow characteristics and prevents clogging or breakage during spinning processes.

- Product uniformity: Consistent viscosity helps maintain uniformity in the quality and properties of the final viscose products.

4. What measures can be implemented to improve the safety of viscose production?

- Proper ventilation: Adequate ventilation systems to remove harmful gases and vapors.

- Personal protective equipment: Providing and enforcing the use of appropriate PPE, such as respirators, gloves, and safety glasses.

- Regular inspections and maintenance: Conducting regular inspections and maintenance to identify and address potential hazards.

- Training and awareness: Providing comprehensive training and safety briefings to employees to enhance their awareness of risks and safe practices.

- Spill prevention and clean-up measures: Establishing protocols for spill containment, clean-up, and disposal of hazardous materials.

5. How do you ensure the quality of viscose solution and monitor its performance?

To ensure the quality of viscose solution and monitor its performance, I follow these steps:

- Raw material inspection: Inspecting incoming raw materials to meet specifications and ensure their suitability for viscose production.

- Process monitoring: Continuously monitoring key process parameters, such as temperature, pressure, and viscosity, to maintain optimal conditions.

- Viscometer testing: Regularly testing the viscosity of the viscose solution to ensure it meets the desired specifications.

- Filtration: Filtering the viscose solution to remove impurities and ensure a smooth spinning process.

- Product testing: Conducting regular quality checks on the final viscose products to assess their properties and meet customer requirements.

6. What are the challenges in managing a viscose cellar operation and how do you overcome them?

- Maintaining optimal conditions: Ensuring a consistent and controlled environment in the viscose cellar to prevent fluctuations in temperature and humidity.

- Equipment maintenance: Regularly servicing and maintaining equipment to prevent breakdowns and ensure smooth production.

- Process optimization: Continuously analyzing and improving production processes to enhance efficiency and reduce downtime.

- Employee safety: Prioritizing the safety of employees by implementing proper safety measures and providing appropriate training.

- Environmental compliance: Ensuring adherence to environmental regulations and minimizing the environmental impact of viscose production.

7. How do you stay updated with the latest advancements in viscose production technology and best practices?

- Attending industry conferences and workshops: Participating in conferences and workshops to gain knowledge about new technologies and best practices.

- Reading technical journals and publications: Regularly reviewing industry journals and publications to stay informed about research and developments.

- Collaboration with experts and suppliers: Consulting with industry experts and suppliers to exchange knowledge and learn about innovative solutions.

- In-house training and development programs: Participating in training programs and workshops within the organization to enhance skills and knowledge.

- Online research and resources: Utilizing online platforms and resources to access the latest information and connect with industry professionals.

8. Explain the role of additives in viscose solution and how they affect the properties of viscose fibers?

Additives play a crucial role in viscose solution and influence the properties of viscose fibers:

- Modifiers: These additives alter the viscosity and gelation properties of the viscose solution, affecting the spinnability and fiber strength.

- Spin finishes: Applied to the viscose fibers during spinning, these additives reduce friction and improve fiber handling.

- Delustrants: Used to create a matte finish on viscose fibers, these additives scatter light and reduce shine.

- Brighteners: Enhance the whiteness and brightness of viscose fibers by absorbing and reflecting light.

- Crosslinking agents: Improve the strength and durability of viscose fibers by forming covalent bonds between cellulose molecules.

9. How do you troubleshoot common problems encountered in viscose production, such as fiber breakage or uneven spinning?

- Fiber breakage: Analyze factors such as viscose viscosity, spinning tension, and equipment settings to identify and resolve the cause.

- Uneven spinning: Examine the spinnerets for blockages or damage, optimize the spinning bath temperature, and adjust the spinning speed as needed.

- Poor fiber quality: Investigate the raw materials, process parameters, and additives used to determine and address the underlying issue.

- Equipment malfunctions: Conduct regular maintenance and inspections to identify and repair any equipment issues promptly.

- Process deviations: Monitor process parameters closely and take corrective actions when deviations occur to maintain optimal production conditions.

10. Describe your experience in implementing process improvements and optimizing viscose production

In my previous role as Viscose Cellar Charge Hand at [Company Name], I successfully implemented several process improvements that optimized viscose production and enhanced overall efficiency:

- Automated viscosity control: Introduced an automated viscosity control system to ensure consistent and precise viscosity monitoring, resulting in improved fiber quality.

- Optimized filtration process: Redesigned the filtration system to improve impurity removal and reduce fiber breakage during spinning.

- Reduced downtime: Implemented a predictive maintenance program to identify and address potential equipment issues before they caused downtime, increasing production uptime.

- Improved safety measures: Enhanced safety protocols and implemented new equipment safeguards to minimize risks and create a safer work environment.

- Increased production capacity: Analyzed production bottlenecks and implemented process optimizations that increased production capacity by 15%.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Viscose Cellar Charge Hand.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Viscose Cellar Charge Hand‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Viscose Cellar Charge Hand plays a pivotal role in the production of viscose, a versatile and widely used material in various industries. Their primary responsibilities include:

1. Production Management

Supervising and coordinating the production operations in the viscose cellar, ensuring adherence to quality standards, safety regulations, and production targets.

- Monitoring the production process, identifying and addressing any bottlenecks or deviations from established parameters.

- Implementing and maintaining production schedules, ensuring timely delivery of orders while optimizing resource utilization.

2. Equipment Maintenance and Operation

Ensuring the proper functioning and maintenance of all equipment, including mixers, filters, pumps, and reactors, to maintain optimal production efficiency.

- Conducting regular inspections, identifying potential issues, and implementing preventive maintenance measures to minimize downtime.

- Troubleshooting and resolving equipment malfunctions promptly, utilizing technical knowledge and experience.

3. Quality Control and Assurance

Monitoring and maintaining product quality throughout the production process, ensuring compliance with specifications and customer requirements.

- Conducting regular quality tests, analyzing results, and implementing corrective actions as necessary.

- Establishing and maintaining quality control procedures, ensuring adherence to industry standards and best practices.

4. Safety Management

Enforcing safety regulations and protocols in the viscose cellar, prioritizing the well-being of employees and the prevention of accidents.

- Conducting safety briefings, ensuring employees understand and follow established procedures.

- Identifying and mitigating potential safety hazards, implementing necessary safety measures to prevent incidents.

5. Team Leadership and Management

Leading and motivating a team of operators, providing guidance, training, and support to enhance performance and productivity.

- Assigning tasks, delegating responsibilities, and monitoring progress to ensure efficient execution of operations.

- Providing performance evaluations, identifying training needs, and supporting professional development for team members.

Interview Tips

To ace your interview for a Viscose Cellar Charge Hand position, it’s crucial to prepare thoroughly and demonstrate your knowledge, skills, and enthusiasm for the role. Here are some tips to help you succeed:

1. Research the Company and Position

Familiarize yourself with the company’s background, products, and industry standing. Research the specific role and its responsibilities, highlighting your alignment with their requirements.

- Check the company website, LinkedIn page, and any available industry reports to gather information.

- Connect with industry professionals or former employees on LinkedIn to gain insights into the company culture and role expectations.

2. Highlight Your Technical Expertise

Emphasize your deep understanding of the viscose production process, equipment operation, and quality control techniques. Provide specific examples of your experience in maintaining and troubleshooting equipment, implementing quality assurance measures, and ensuring safety compliance.

- Quantify your accomplishments using specific metrics, such as improved production efficiency, reduced downtime, or enhanced product quality.

- Discuss any industry certifications or training programs you have completed to demonstrate your commitment to professional development.

3. Showcase Your Leadership Abilities

Highlight your experience in leading and motivating teams, effectively delegating tasks, and fostering a positive and productive work environment. Provide examples of how you have coached and developed team members, resolved conflicts, and inspired them to achieve goals.

- Use the STAR method (Situation, Task, Action, Result) to structure your responses and provide specific examples of your leadership skills.

- Quantify your accomplishments by mentioning the number of team members you led, the improvements you implemented, or the recognition you received.

4. Prepare for Common Interview Questions

Anticipate common interview questions and prepare your responses accordingly. Practice answering questions about your experience in the viscose industry, your technical capabilities, your leadership style, and your motivation for pursuing this role.

- Research common interview questions online or consult with a career counselor for guidance.

- Rehearse your answers out loud to improve your delivery and confidence.

5. Ask Informed Questions

At the end of the interview, prepare thoughtful questions to ask the interviewer. This demonstrates your interest, engagement, and desire to learn more about the role and the company. Research the company and industry to identify insightful questions.

- Ask about the company’s future plans, expansion strategies, or sustainability initiatives.

- Inquire about the specific challenges and opportunities associated with the role and how they plan to address them.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Viscose Cellar Charge Hand, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Viscose Cellar Charge Hand positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.