Feeling lost in a sea of interview questions? Landed that dream interview for Automatic Centrifugal Station Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Automatic Centrifugal Station Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

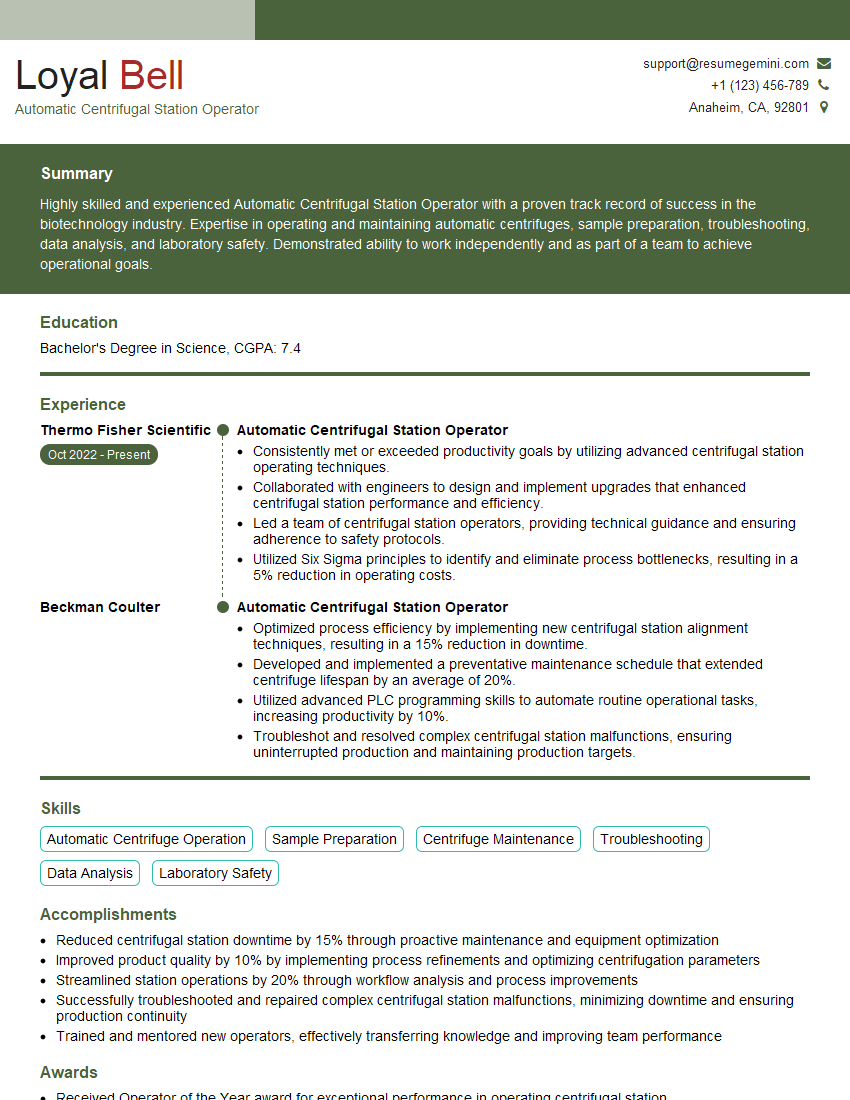

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Centrifugal Station Operator

1. What are the key responsibilities of an Automatic Centrifugal Station Operator?

The key responsibilities of an Automatic Centrifugal Station Operator include:

- Operating and monitoring automatic centrifugal station equipment

- Loading and unloading materials into and from the centrifugal station

- Setting up and adjusting machine parameters to ensure optimal performance

- Monitoring the centrifugal process to identify and correct any abnormalities

- Maintaining a clean and safe work area

2. Describe the different types of centrifugal stations and their applications.

There are two main types of centrifugal stations: horizontal and vertical.

Horizontal Centrifugal Stations

- Used for a wide range of applications, including liquid-solid separation

- Material is fed into the station horizontally and is separated by centrifugal force

Vertical Centrifugal Stations

- Used for applications where high centrifugal force is required

- Material is fed into the station vertically and is separated by centrifugal force

3. What are the safety precautions that must be taken when operating a centrifugal station?

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs

- Ensure that the centrifugal station is properly installed and grounded

- Do not operate the centrifugal station if it is damaged or malfunctioning

- Keep the work area clean and free of debris

- Follow all manufacturer’s instructions for safe operation

4. How do you troubleshoot common problems that may occur with a centrifugal station?

- Material is not being separated properly: Check the feed rate, speed, and other machine parameters. Ensure that the material is suitable for centrifugal separation.

- The centrifugal station is vibrating excessively: Check the balance of the machine and the load. Ensure that the station is properly mounted and leveled.

- The centrifugal station is making noise: Check the bearings and other moving parts for wear or damage. Ensure that the machine is properly lubricated.

5. How do you maintain a centrifugal station?

Regular maintenance is essential to ensure the optimal performance and longevity of a centrifugal station.

- Daily: Clean the station and inspect for any damage or wear

- Weekly: Lubricate the bearings and other moving parts

- Monthly: Calibrate the machine and check the electrical connections

- Annually: Perform a comprehensive inspection of the station and replace any worn or damaged parts

6. What are the environmental regulations that apply to the operation of a centrifugal station?

The environmental regulations that apply to the operation of a centrifugal station vary depending on the location of the station.

- In the United States, the Environmental Protection Agency (EPA) regulates the emissions from centrifugal stations.

- In the European Union, the European Commission regulates the emissions from centrifugal stations.

7. What are the latest trends in centrifugal station technology?

The latest trends in centrifugal station technology include:

- The development of more efficient and environmentally friendly stations

- The use of automation and control systems to improve station performance

- The development of new materials and coatings to improve station durability

8. What are the challenges that you have faced in your previous role as an Automatic Centrifugal Station Operator?

- Troubleshooting complex problems: I have experience troubleshooting a variety of problems with centrifugal stations, including material separation issues, vibration, and noise.

- Meeting production targets: I have consistently met or exceeded production targets in my previous role.

- Working in a team environment: I am a team player and have experience working with a variety of people in different roles.

9. What are your career goals?

My career goal is to become a Centrifugal Station Supervisor. I am confident that I have the skills and experience necessary to be successful in this role.

10. Why are you interested in this position?

I am interested in this position because I am passionate about centrifugal separation technology. I am eager to learn more about this technology and to contribute to the success of your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Centrifugal Station Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Centrifugal Station Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Automatic Centrifugal Station Operator is primarily responsible for overseeing the operation of specialized centrifugal machinery and ensuring its optimal performance. Key responsibilities include:

1. Operation and Maintenance

Operate and maintain centrifugal station and associated equipment.

- Control and monitor the centrifugal process, ensuring proper speed, temperature, and other critical parameters.

- Perform regular maintenance tasks, including equipment cleaning, lubrication, and minor repairs.

2. Quality Control

Inspect and ensure the quality of centrifugal separation process.

- Monitor product quality and adjust process parameters to meet specifications.

- Conduct quality control tests and maintain records of production data.

3. Process Optimization

Analyze and identify opportunities for process improvement.

- Troubleshoot and resolve operational issues, minimizing downtime and optimizing productivity.

- Suggest and implement process modifications to enhance efficiency or reduce costs.

4. Safety and Compliance

Adhere to safety and environmental regulations.

- Follow established safety protocols and wear appropriate safety gear.

- Maintain a clean and organized work area, adhering to industry standards.

Interview Tips

To ace the interview for the Automatic Centrifugal Station Operator position, consider the following tips:

1. Research the Company and Industry

Demonstrate your knowledge of the company’s operations, industry trends, and the specific role.

- Review the company’s website, industry news, and LinkedIn profiles of relevant employees.

- Prepare questions about the company’s growth plans, market challenges, and sustainability initiatives.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills, operational knowledge, and problem-solving abilities related to centrifugal separation.

- Quantify your accomplishments and provide specific examples of how you improved processes or resolved issues.

- Highlight your ability to work independently and as part of a team.

3. Emphasize Safety and Quality

Showcase your commitment to safety and quality standards in the workplace.

- Describe your experience with safety protocols and accident prevention measures.

- Explain how you prioritize product quality and maintain compliance with industry regulations.

4. Prepare Technical Questions

Anticipate technical questions related to centrifugal separation and prepare thoughtful responses.

- Review principles of centrifugal force, separation efficiency, and process optimization techniques.

- Practice troubleshooting common operational issues and provide potential solutions.

5. Ask Meaningful Questions

Engage with the interviewer and ask insightful questions that demonstrate your interest and enthusiasm.

- Inquire about the company’s investment in technology and automation.

- Ask about opportunities for professional development and career growth.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Automatic Centrifugal Station Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Automatic Centrifugal Station Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.