Are you gearing up for a career in Batch or Continuous Still Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Batch or Continuous Still Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

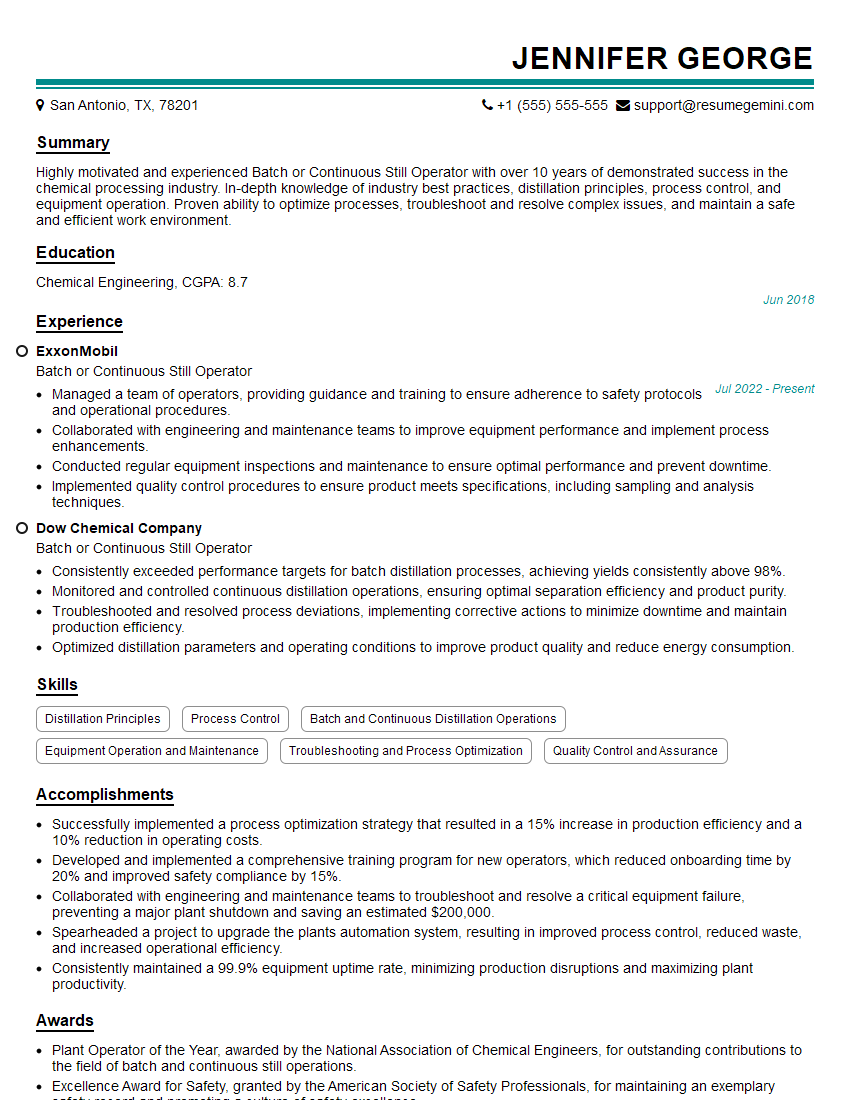

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Batch or Continuous Still Operator

1. Describe the key responsibilities of a Batch or Continuous Still Operator.

- Operate and control batch or continuous stills to produce distilled spirits according to established specifications and production schedules.

- Monitor and maintain process parameters such as temperature, pressure, and flow rates to ensure optimal distillation efficiency.

- Conduct quality control checks on raw materials and finished products to ensure adherence to quality standards.

- Troubleshoot and resolve process malfunctions to minimize downtime and maintain production efficiency.

- Maintain a clean and organized work area to comply with safety and sanitation regulations.

2. Explain the differences between batch and continuous distillation processes.

Batch Distillation

- Involves processing a fixed quantity of liquid in a single vessel.

- Requires multiple stages of heating, cooling, and condensation.

- Suitable for producing small batches of specialized spirits.

Continuous Distillation

- Feeds liquid continuously into the still, while simultaneously removing distilled vapors.

- Maintains a steady state process, resulting in consistent product quality.

- Ideal for large-scale production of standard spirits.

3. How do you ensure the consistency and quality of distilled spirits?

- Adhere to established production procedures and quality standards.

- Conduct regular quality checks on raw materials and intermediate products.

- Monitor and adjust process parameters to optimize distillation efficiency.

- Document all quality control activities and maintain accurate records.

- Collaborate with quality control personnel to analyze product quality and identify areas for improvement.

4. How do you handle process malfunctions and equipment breakdowns?

- Identify the source of the malfunction or breakdown promptly.

- Isolate the affected equipment or process to prevent further damage.

- Troubleshoot the issue using established procedures and technical knowledge.

- Repair or replace faulty components as necessary.

- Monitor the process to ensure that it is operating properly after repairs.

5. What safety precautions should be taken when operating a batch or continuous still?

- Wear appropriate personal protective equipment, including gloves, safety glasses, and a mask.

- Follow established safety procedures for handling flammable liquids and gases.

- Maintain a clean and organized work area to prevent tripping or slipping hazards.

- Be aware of the potential for spills and leaks, and have appropriate cleanup materials readily available.

- Receive regular safety training and participate in safety drills.

6. What is the importance of maintaining a clean and organized work area?

- Ensures safety by minimizing tripping or slipping hazards.

- Prevents contamination of products and equipment.

- Facilitates efficient and effective operation by providing clear access to equipment and materials.

- Promotes a professional and hygienic work environment.

- Complies with safety and sanitation regulations.

7. How do you stay up-to-date on the latest industry trends and best practices?

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Participate in online forums and discussion groups.

- Seek mentorship from experienced professionals in the field.

- Undertake continuing education programs to enhance knowledge and skills.

8. What is your understanding of the role of automation in modern distillation processes?

- Improves efficiency and productivity by automating repetitive tasks.

- Enhances precision and accuracy in process control.

- Reduces the risk of human error and improves product consistency.

- Enables remote monitoring and control of distillation processes.

- Provides data for analysis and process optimization.

9. How do you approach a new distillation recipe or process?

- Review the recipe or process thoroughly.

- Identify any unfamiliar ingredients or techniques.

- Consult with more experienced operators or the production manager for guidance.

- Follow the instructions carefully and make any necessary adjustments based on experience.

- Monitor the process closely and make adjustments as needed to achieve the desired results.

10. What is your experience with working in a team environment?

- Collaborated with colleagues to resolve production issues.

- Shared knowledge and expertise with team members.

- Supported team goals and objectives.

- Communicated effectively with team members and supervisors.

- Participated in team meetings and discussions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Batch or Continuous Still Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Batch or Continuous Still Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Batch or Continuous Still Operators are responsible for operating and maintaining batch or continuous stills used in the production of alcoholic beverages, such as whiskey, vodka, and gin. Their key job responsibilities include:

1. Operating stills

Batch still operators manually control the distillation process, while continuous still operators monitor and adjust automated systems. Both types of operators must ensure that stills are operating efficiently and producing high-quality distillate.

2. Monitoring process variables

Operators constantly monitor process variables such as temperature, pressure, and flow rate to ensure that the distillation process is proceeding as planned. They make adjustments as necessary to maintain optimal conditions.

3. Conducting quality control tests

Operators conduct quality control tests on the distillate to ensure that it meets specifications. They also collect samples for laboratory analysis.

4. Maintaining equipment

Operators perform routine maintenance on stills and other equipment to keep them in good working order. They also troubleshoot and repair problems as they arise.

Interview Tips

To ace an interview for a Batch or Continuous Still Operator position, candidates should:

1. Research the company and the position

Candidates should learn as much as they can about the company and the specific position they are applying for. This will help them understand the company’s culture and values, as well as the specific skills and experience required for the job.

2. Practice answering common interview questions

Candidates should practice answering common interview questions, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. They should also be prepared to discuss their experience and skills in detail.

3. Dress professionally and arrive on time

Candidates should dress professionally and arrive on time for their interview. This will show the interviewer that they are serious about the position and that they respect the company’s time.

4. Be enthusiastic and positive

Candidates should be enthusiastic and positive throughout the interview. This will show the interviewer that they are excited about the opportunity and that they are a positive addition to the team.

Next Step:

Now that you’re armed with the knowledge of Batch or Continuous Still Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Batch or Continuous Still Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini