Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Carbonation Equipment Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Carbonation Equipment Operator so you can tailor your answers to impress potential employers.

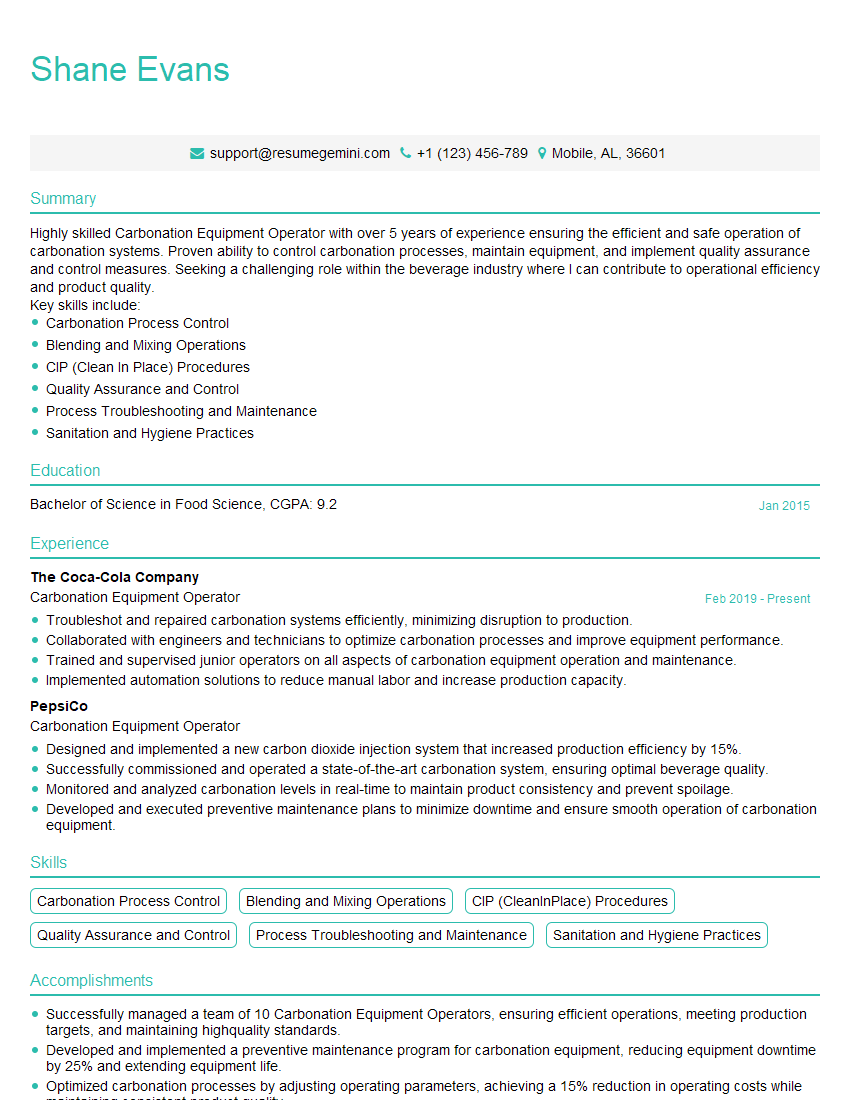

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Carbonation Equipment Operator

1. What are the key responsibilities of a Carbonation Equipment Operator?

- Operate and maintain carbonation equipment, including chillers, cooling towers, compressors, and carbon dioxide tanks.

- Monitor and control carbon dioxide levels in beverages.

- Ensure that carbonation equipment is operating safely and efficiently.

- Troubleshoot and resolve any problems with carbonation equipment.

- Maintain a clean and organized work area.

2. What are the safety protocols that you follow when working with carbonation equipment?

- Never work on carbonation equipment without proper training and authorization.

- Always wear appropriate personal protective equipment, including safety glasses, gloves, and a lab coat.

- Never smoke or eat near carbonation equipment.

- Never leave carbonation equipment unattended.

- Always follow the manufacturer’s instructions for operating and maintaining carbonation equipment.

3. How do you troubleshoot and resolve problems with carbonation equipment?

- First, try to identify the source of the problem by observing the equipment and its surroundings.

- Once the source of the problem has been identified, consult the manufacturer’s instructions for troubleshooting and repair.

- If the problem cannot be resolved by following the manufacturer’s instructions, contact a qualified technician.

4. What is the importance of maintaining a clean and organized work area when working with carbonation equipment?

A clean and organized work area helps to prevent accidents and injuries. It also makes it easier to identify and resolve problems with carbonation equipment.

5. What are the different types of carbonation equipment that you have experience working with?

- Chillers

- Cooling towers

- Compressors

- Carbon dioxide tanks

6. What is the purpose of a chiller in a carbonation system?

A chiller is used to cool the beverage before it is carbonated. This helps to reduce the amount of carbon dioxide that is lost during the carbonation process.

7. What is the purpose of a cooling tower in a carbonation system?

A cooling tower is used to cool the water that is used to chill the beverage. This helps to ensure that the beverage is cooled to the desired temperature.

8. What is the purpose of a compressor in a carbonation system?

A compressor is used to compress the carbon dioxide gas before it is injected into the beverage. This helps to increase the amount of carbon dioxide that is dissolved in the beverage.

9. What is the purpose of a carbon dioxide tank in a carbonation system?

A carbon dioxide tank stores the carbon dioxide gas that is used to carbonate the beverage.

10. What are the different types of beverages that can be carbonated?

- Soft drinks

- Beer

- Wine

- Sparkling water

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Carbonation Equipment Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Carbonation Equipment Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Carbonation Equipment Operators are responsible for the safe and efficient operation, maintenance, and troubleshooting of carbonation equipment in food and beverage manufacturing facilities.

1. Equipment Operation

Operate and monitor carbonation equipment, including tanks, compressors, and chillers.

- Set and adjust equipment parameters to ensure proper carbonation levels and quality.

- Monitor equipment performance to identify potential issues and take corrective actions.

2. Equipment Maintenance

Perform regular maintenance on carbonation equipment, including cleaning, inspection, and repairs.

- Follow established maintenance schedules and procedures.

- Identify and replace worn or damaged parts.

3. Troubleshooting

Troubleshoot and repair equipment malfunctions or issues.

- Identify the root cause of problems using diagnostic tools and techniques.

- Implement corrective actions to restore equipment to optimal performance.

4. Quality Control

Monitor and ensure the quality of carbonated products, such as beverages and food items.

- Perform quality checks to verify carbonation levels, pH, and other quality parameters.

- Make adjustments to equipment settings as needed to meet quality standards.

Interview Tips

Preparing for a Carbonation Equipment Operator interview requires a combination of technical knowledge and soft skills.

1. Technical Knowledge

Familiarize yourself with the different types of carbonation equipment, their components, and their operation.

- Review job descriptions and industry-specific publications to identify essential skills and qualifications.

- Research common troubleshooting techniques and best practices for maintaining carbonation equipment.

2. Soft Skills

Emphasize your ability to work independently, solve problems, and communicate effectively.

- Highlight your experience in following instructions, adhering to safety protocols, and working in a team environment.

- Prepare examples of how you have successfully resolved equipment issues or improved processes.

3. Industry Knowledge

Demonstrate your understanding of the food and beverage industry, including the importance of product quality and safety.

- Research the company you are applying to and their specific products and processes.

- Stay informed about industry regulations and best practices related to carbonation equipment operation.

4. Preparation

Practice answering common interview questions, such as those related to your experience with carbonation equipment, troubleshooting techniques, and safety procedures.

- Use the STAR method (Situation, Task, Action, Result) to provide detailed and specific examples in your answers.

- Dress professionally and arrive on time for the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Carbonation Equipment Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!