Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Centrifugal Station Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

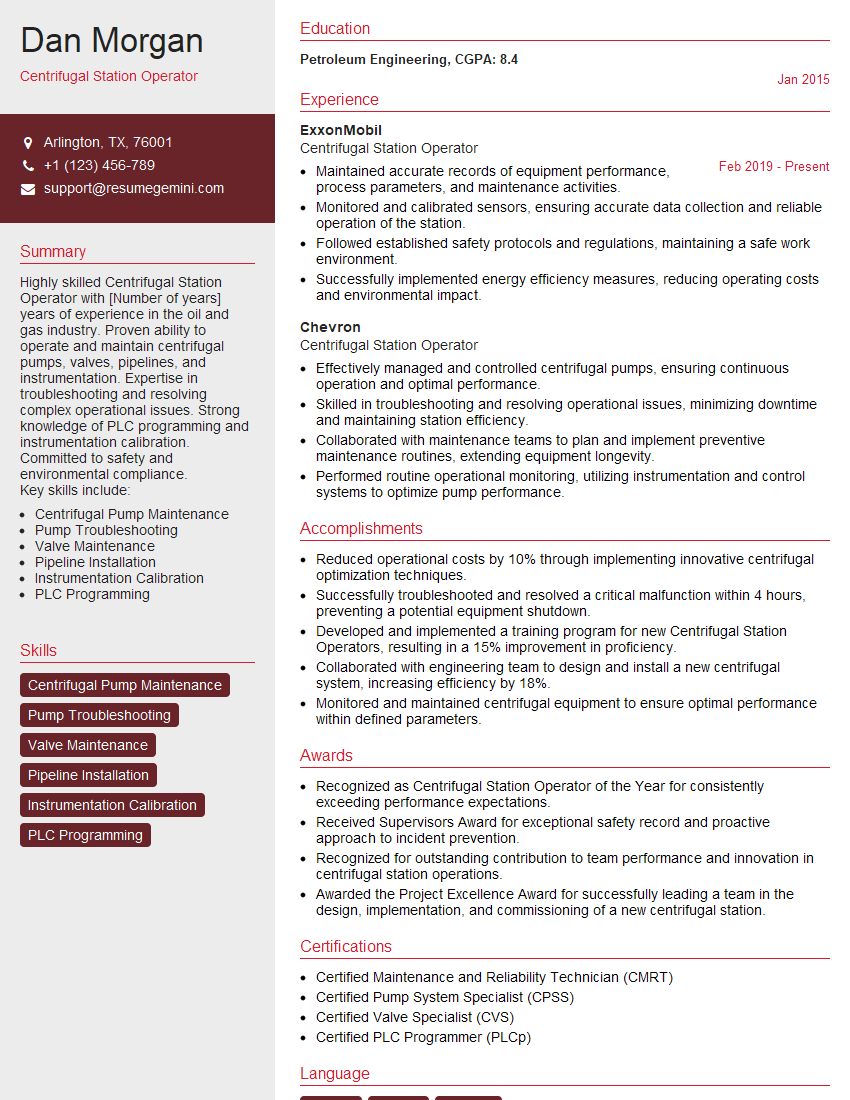

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Centrifugal Station Operator

1. What are the key components of a centrifugal pump and their functions?

A centrifugal pump consists of several key components, each with its own specific function:

- Impeller: The impeller is a rotating component that imparts centrifugal force to the fluid, causing it to move outward from the center.

- Casing: The casing is a stationary component that encloses the impeller and provides a channel for the fluid to flow through.

- Suction and discharge ports: The suction port allows the fluid to enter the pump, while the discharge port allows the fluid to exit.

- Shaft: The shaft connects the impeller to the motor or other power source, allowing the impeller to rotate.

- Bearings: Bearings support the shaft and reduce friction during rotation.

2. Explain the difference between head and flow rate in a centrifugal pump.

- Head: Head refers to the energy imparted to the fluid by the pump, measured in units of height (e.g., meters or feet). It represents the vertical distance that the fluid can be lifted or the pressure it can produce.

- Flow rate: Flow rate refers to the volume of fluid that passes through the pump in a given unit of time, typically measured in cubic meters per second (m³/s) or gallons per minute (gpm).

- These two parameters are inversely related, meaning that increasing the head typically results in a decrease in flow rate, and vice versa.

3. How do you calculate the efficiency of a centrifugal pump?

The efficiency of a centrifugal pump is calculated as the ratio of the power output (hydraulic power) to the power input (mechanical power):

Efficiency = (Density × Gravity × Flow Rate × Head) / (Power Input)

- Density: Density of the fluid (kg/m³)

- Gravity: Acceleration due to gravity (9.81 m/s²)

- Flow Rate: Volume flow rate (m³/s)

- Head: Pump head (m)

- Power Input: Mechanical power input to the pump (kW)

4. What are the common causes of vibration in a centrifugal pump?

- Unbalanced impeller: An impeller that is not properly balanced can cause vibrations due to uneven distribution of mass.

- Misalignment: Misalignment between the pump shaft and the motor or other components can lead to vibrations.

- Bearing wear: Worn bearings can cause excessive vibration due to increased clearances.

- Resonance: If the pump operates at a frequency close to its natural resonant frequency, it can experience excessive vibrations.

- Cavitation: The formation and collapse of vapor bubbles in the pump can cause vibrations and damage to the impeller.

5. How would you troubleshoot a centrifugal pump that is not delivering the desired flow rate?

- Check the suction conditions: Ensure that there is no blockage or restriction in the suction line or at the pump inlet.

- Inspect the impeller: Check for any damage or wear to the impeller, as this can affect flow rate.

- Verify the operating conditions: Ensure that the pump is operating at the correct speed and with the appropriate head and flow rate requirements.

- Examine the discharge line: Check for any blockages or restrictions in the discharge line or at the pump outlet.

- Monitor system pressure: Measure the pressure at the pump discharge and compare it to the design specifications.

6. What safety precautions should be taken when operating a centrifugal pump?

- Wear appropriate personal protective equipment (PPE): This includes safety glasses, gloves, and hearing protection.

- Follow lockout/tagout procedures: Ensure that the pump is properly isolated and de-energized before performing any maintenance or repairs.

- Check for leaks: Regularly inspect the pump and piping system for any leaks or signs of damage.

- Be aware of potential hazards: Be aware of potential hazards such as rotating parts, hot surfaces, and high-pressure fluid.

- Follow manufacturer’s instructions: Always follow the manufacturer’s instructions for safe operation and maintenance of the pump.

7. Describe the process of priming a centrifugal pump.

Priming involves removing air from the pump and suction line to allow the pump to operate properly. The method of priming depends on the specific pump design:

Self-priming pumps:

- These pumps have a built-in mechanism to remove air automatically.

- They can typically prime themselves with a small amount of liquid in the pump casing.

Manually primed pumps:

- These pumps require manual filling of the pump casing with liquid before starting.

- This can be done using a funnel or by connecting a hose to the pump inlet and filling it with liquid.

8. What is the purpose of a relief valve in a centrifugal pump system?

- A relief valve is a safety device that protects the pump and system from excessive pressure.

- It opens when the pressure in the system exceeds a predetermined setpoint, allowing excess fluid to bypass the pump and return to the suction side.

- This prevents damage to the pump and other components due to overpressure.

9. How do you adjust the flow rate of a centrifugal pump?

- Variable speed drive (VSD): A VSD can be used to control the speed of the pump motor, which in turn adjusts the flow rate.

- Throttle valve: A throttle valve installed on the discharge line can be used to restrict the flow and reduce the flow rate.

- Variable pitch impeller: Some pumps have impellers with adjustable blades, allowing for changes in flow rate by altering the blade angle.

- Bypass valve: A bypass valve can be used to divert a portion of the flow back to the suction side, reducing the net flow rate.

10. What is cavitation in a centrifugal pump and how can it be prevented?

- Cavitation: Cavitation is the formation and collapse of vapor bubbles in the pump due to local pressure drops below the vapor pressure of the fluid.

- Prevention measures:

- Ensure proper suction conditions to avoid low pressure at the pump inlet.

- Select a pump with an impeller design that minimizes cavitation.

- Maintain a sufficient net positive suction head (NPSH) to prevent cavitation.

- Use a cavitation suppressor to absorb cavitation energy and reduce bubble formation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Centrifugal Station Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Centrifugal Station Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Centrifugal Station Operator is responsible for the safe and efficient operation and maintenance of centrifugal pumps and associated equipment in a pumping station. Their key responsibilities include:

1. Operating and Monitoring Equipment

Starting, stopping, and monitoring the operation of centrifugal pumps, motors, and other related equipment.

- Maintaining proper operating conditions, such as flow rates, pressures, and temperatures.

- Monitoring and recording operating data, such as flow rates, pressures, and power consumption.

2. Maintaining and Inspecting Equipment

Conducting regular inspections of pumps, motors, and other equipment to identify potential problems.

- Performing preventive maintenance tasks, such as lubrication, cleaning, and adjustments.

- Repairing or replacing worn or damaged parts.

3. Troubleshooting and Problem Solving

Identifying and resolving problems with pumps, motors, and other equipment.

- Analyzing operating data and identifying potential issues.

- Taking corrective actions to resolve problems and restore normal operation.

4. Ensuring Safety and Compliance

Ensuring that all operations are conducted in a safe and compliant manner.

- Following established safety protocols and procedures.

- Maintaining a clean and organized work area.

Interview Tips

To prepare for an interview for a Centrifugal Station Operator position, it is important to highlight your relevant skills and experience. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will give you a better understanding of the company’s values, culture, and the specific responsibilities of the role.

- Visit the company’s website to learn about their mission, products, and services.

- Read industry news and articles to stay up-to-date on the latest trends and technologies.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?”. It’s helpful to practice answering these questions beforehand so that you can deliver clear and concise responses during the interview.

- Prepare a brief overview of your skills and experience, highlighting those that are most relevant to the position.

- Research the company and the industry so that you can speak intelligently about your interest in the role.

3. Be Prepared to Discuss Your Experience

The interviewer will likely ask you about your previous experience in the field. Be prepared to discuss your responsibilities, accomplishments, and any challenges you faced in your previous roles.

- Use the STAR method (Situation, Task, Action, Result) to answer questions about your experience.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role.

- Prepare a few questions that you would like to ask the interviewer about the company, the position, or the industry.

- Don’t be afraid to ask for clarification if you don’t understand something.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Centrifugal Station Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!