Are you gearing up for a career in Dorr Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Dorr Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

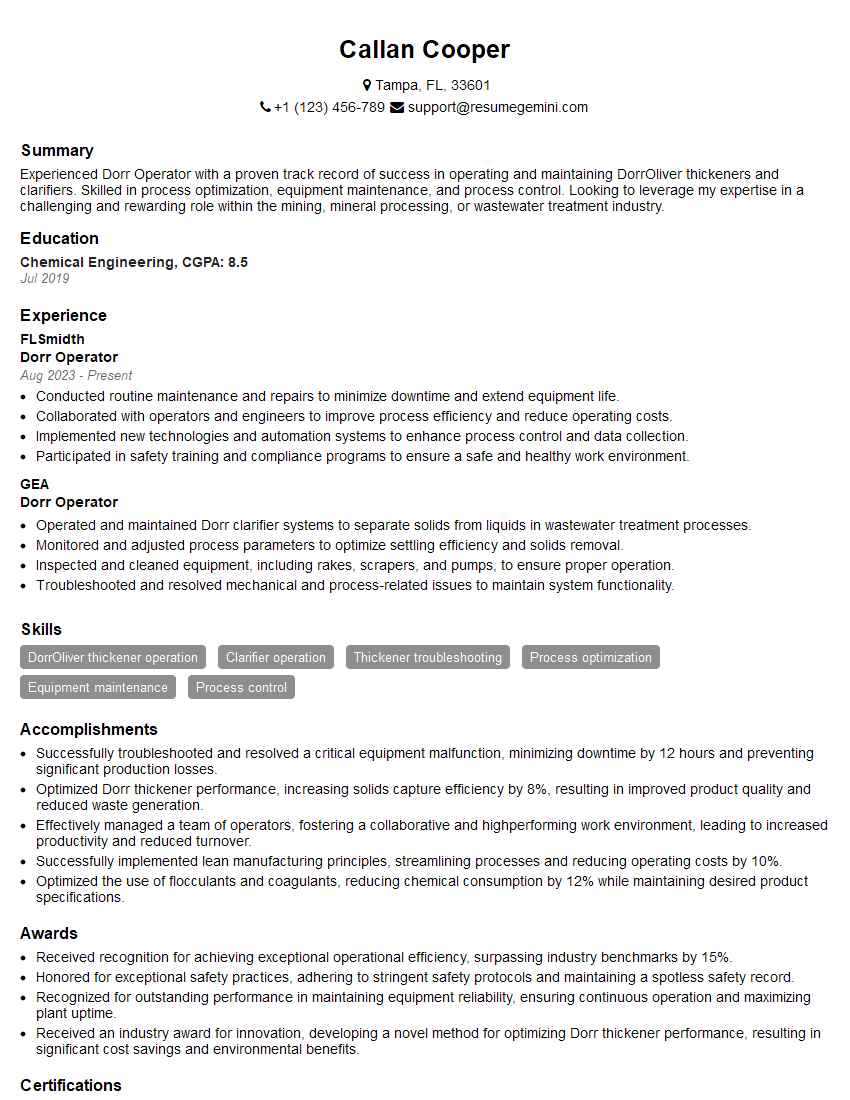

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dorr Operator

1. Describe the role of a Dorr Operator in a typical mining operation?

The Dorr Operator plays a crucial role in the mining operation, primarily responsible for operating and maintaining the Dorr thickener, a critical component in the mineral processing stage. Their key responsibilities include:

- Monitoring and controlling the feed rate and density of the slurry entering the thickener.

- Adjusting the thickener settings to optimize the separation of solids from liquids.

- Maintaining the equipment’s mechanical and electrical systems to ensure smooth operation.

2. Explain the process of flocculation and its importance in Dorr thickener operation?

What are the different types of flocculants used?

- Flocculation is a process where chemicals are added to the slurry to promote the formation of larger flocs or clumps of solids.

- These larger flocs settle more efficiently, increasing the separation rate and improving the clarity of the overflow solution.

- Common types of flocculants include organic polymers, inorganic salts, and natural materials like starch.

How do you determine the optimal dosage of flocculants?

- The optimal dosage of flocculants is determined through laboratory testing or trial and error.

- Factors to consider include the type of solids, slurry chemistry, and desired settling rate.

- Excessive dosage can lead to poor settling, while insufficient dosage may not achieve the desired separation.

3. How do you troubleshoot common problems encountered in Dorr thickener operation?

Common problems in Dorr thickener operation include:

- Poor settling: caused by insufficient flocculation, high feed rate, or mechanical issues.

- Turbid overflow: caused by inadequate flocculation, too high feed density, or worn-out rakes.

- Mechanical breakdowns: such as gear failures, bearing issues, or leaks.

- Electrical problems: such as motor failures or control system malfunctions.

Troubleshooting involves:

- Identifying the symptoms and potential causes.

- Inspecting the equipment and checking operating parameters.

- Making adjustments or repairs as necessary.

4. Describe the safety precautions that must be observed when working with Dorr thickeners?

Safety precautions for working with Dorr thickeners include:

- Wearing appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Being aware of potential hazards such as rotating equipment, slippery surfaces, and chemical spills.

- Following proper lockout/tagout procedures before performing maintenance or repairs.

- Maintaining a clean and organized work area.

- Reporting any unsafe conditions or incidents immediately.

5. How do you ensure the efficient operation of the Dorr thickener and maximize its performance?

To ensure efficient operation and maximize performance, Dorr Operators should:

- Monitor and control feed rate and density within the optimal range.

- Optimize flocculant dosage for effective solids settling.

- Regularly inspect and maintain the equipment to prevent breakdowns.

- Keep the thickener clean and free of debris to maintain settling efficiency.

- Record and analyze operating data to identify areas for improvement.

6. Explain the principles of rake mechanism in a Dorr thickener. How does it contribute to the separation process?

What are the different types of rake mechanisms?

- The rake mechanism consists of rotating arms with rakes that slowly move the settled solids towards the discharge point.

- Types of rake mechanisms include center-drive and peripheral-drive rakes.

How does the rake speed and rake angle affect the separation process?

- Rake speed and angle need to be optimized to prevent re-suspension of settled solids.

- Too high speed or angle can cause solids to be carried over to the overflow.

7. Describe the role of underflow and overflow streams in the Dorr thickener operation. How do you optimize the ratio between them?

The underflow stream is the concentrated solids discharged from the thickener, while the overflow stream is the clarified liquid.

Optimizing the underflow to overflow ratio involves:

- Adjusting feed rate, flocculant dosage, and rake speed.

- Monitoring solids concentration in the underflow to ensure efficient solids removal.

- Maintaining a clear overflow with minimal solids carryover.

8. Explain the importance of monitoring and controlling the pH levels in the Dorr thickener. How does pH affect the flocculation process?

pH levels impact the effectiveness of flocculants and the settling process.

- Optimal pH range for flocculation depends on the type of flocculant and the characteristics of the slurry.

- Incorrect pH levels can result in poor flocculation and inefficient solids separation.

Monitoring and controlling pH involves:

- Regularly checking pH levels using pH meters or test kits.

- Adjusting pH as necessary using pH modifiers (acids or bases).

9. Describe the maintenance procedures for Dorr thickeners. How often should they be performed?

Regular maintenance is crucial to ensure optimal performance and prevent breakdowns.

Maintenance procedures include:

- Daily: Inspecting equipment for any damage, leaks, or loose parts.

- Weekly: Lubricating moving parts, cleaning the thickener, and checking flocculant dosage.

- Monthly: Conducting more thorough inspections, including checking rake mechanism and gearboxes.

- Annually: Performing major overhauls, replacing worn-out components, and calibrating instruments.

10. How do you handle emergency situations such as equipment breakdowns or spills in the Dorr thickener area?

Emergency situations require prompt and effective action.

- Assess the situation and identify the potential hazards.

- Follow established emergency response procedures.

- Isolate the affected area and evacuate personnel if necessary.

- Contact the appropriate emergency services or maintenance team.

- Document the incident and investigate the cause to prevent future occurrences.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dorr Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dorr Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Dorr Operator is responsible for the operation and maintenance of Dorr thickeners, clarifiers, and other related equipment in a mining or industrial setting. Key job responsibilities include:

1. Equipment Operation

Operate and monitor Dorr thickeners, clarifiers, and other related equipment to separate solids from liquids.

- Control the flow of materials through the equipment to achieve desired separation and clarification results.

- Adjust process parameters such as speed, temperature, and pH to optimize performance.

2. Equipment Maintenance

Perform routine maintenance and repairs on Dorr equipment to ensure optimal operation.

- Inspect and clean equipment components, including pumps, gears, and bearings.

- Lubricate and adjust equipment as necessary to prevent breakdowns.

3. Process Monitoring

Monitor the clarification and thickening process to ensure that it meets quality standards.

- Collect and analyze samples of solids and liquids to determine their properties.

- Make adjustments to the process as needed to improve efficiency and product quality.

4. Safety and Compliance

Adhere to all safety regulations and procedures related to the operation of Dorr equipment.

- Wear appropriate personal protective equipment (PPE) at all times.

- Follow established lockout/tagout procedures when performing maintenance.

Interview Tips

To ace an interview for a Dorr Operator position, candidates should prepare thoroughly and demonstrate their technical skills and knowledge of the industry. Here are some tips and hacks:

1. Research the Company and Position

Research the company’s operations, the specific role you are applying for, and the industry in which they operate. This will help you understand the company’s goals, the requirements of the position, and the technical challenges you may encounter.

- Visit the company’s website and social media pages.

- Read industry news and articles.

2. Highlight Your Technical Skills

Dorr Operators are responsible for operating and maintaining complex equipment, so it is essential to highlight your technical skills and knowledge during the interview. Provide specific examples of your experience with Dorr thickeners, clarifiers, and related equipment.

- Describe your experience with process control, including setting and adjusting process parameters.

- Explain your knowledge of equipment maintenance, including troubleshooting and repair procedures.

3. Emphasize Safety and Compliance

Safety is paramount in any industrial setting, but particularly in mining and heavy industry. Highlight your commitment to safety and compliance during the interview. Provide examples of your experience with safety protocols, including PPE, lockout/tagout procedures, and emergency response.

- Describe your experience with conducting safety inspections.

- Explain how you ensure compliance with OSHA and other regulatory standards.

4. Showcase Your Problem-Solving Abilities

Dorr Operators often encounter unexpected challenges and must be able to solve problems quickly and effectively. During the interview, provide examples of your problem-solving skills, particularly in relation to Dorr equipment or industrial processes.

- Describe a time when you successfully diagnosed and repaired a problem with a Dorr thickener.

- Explain how you improved the efficiency of a clarification process by modifying process parameters.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dorr Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.