Are you gearing up for a career in Fermentation Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Fermentation Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

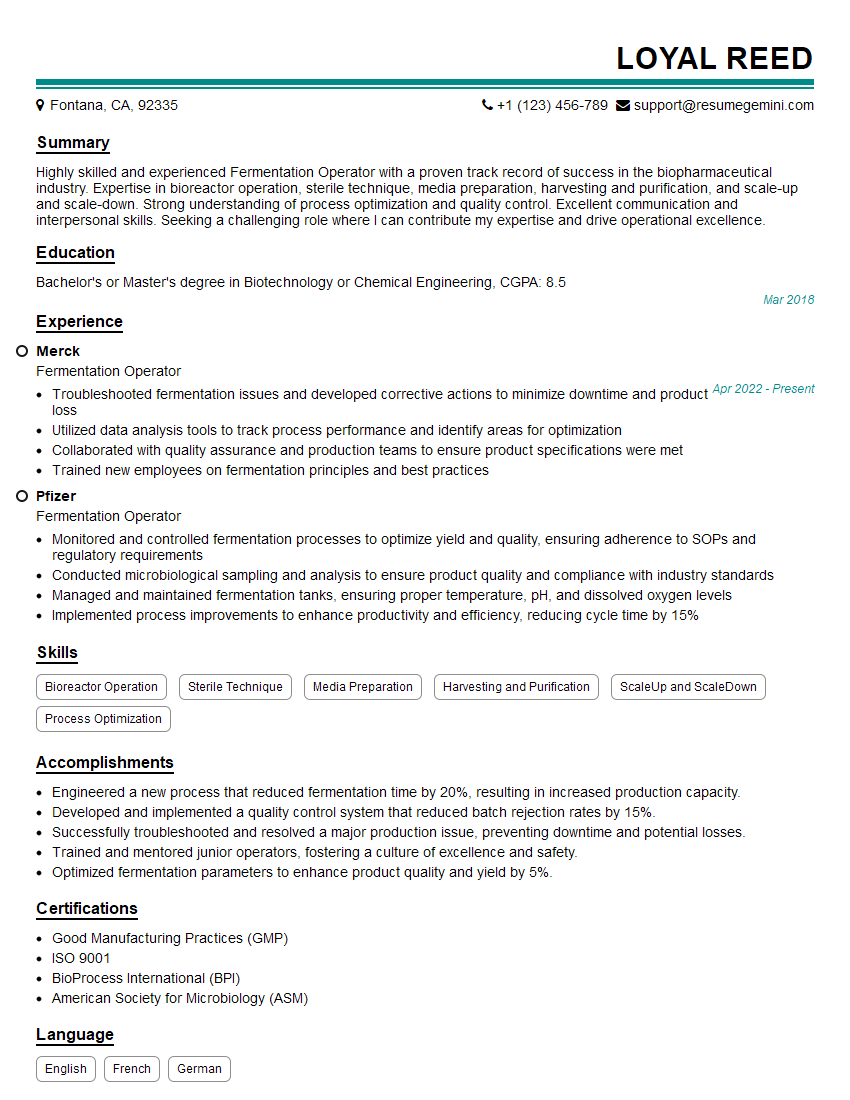

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fermentation Operator

1. Explain the role of a fermentation operator in the production of biopharmaceuticals?

As a Fermentation Operator, I play a crucial role in the production of biopharmaceuticals by:

- Monitoring and controlling fermentation processes to ensure optimal conditions for cell growth and product formation.

- Maintaining sterile environments to prevent contamination.

- Performing sampling and testing to monitor process parameters and product quality.

- Troubleshooting and resolving process deviations to maintain productivity and efficiency.

- Following established protocols and adhering to regulatory guidelines.

2. Describe the key steps involved in optimizing a fermentation process.

Process Monitoring

- Monitoring temperature, pH, dissolved oxygen, and other critical parameters.

- Collecting data and analyzing trends to identify areas for improvement.

Process Control

- Adjusting process parameters (e.g., feed rates, agitation) to maintain optimal conditions.

- Implementing control strategies (e.g., feedback loops) to ensure stability and consistency.

Process Optimization

- Evaluating process performance and identifying bottlenecks.

- Implementing modifications (e.g., media composition, fermentation time) to enhance efficiency and yield.

3. Discuss the importance of maintaining sterility in a fermentation process.

Maintaining sterility is paramount in fermentation processes to prevent contamination by microorganisms that can affect product quality and safety.

- Contamination can lead to decreased cell viability, reduced product yield, and potential health risks.

- Sterility is achieved through rigorous cleaning and sterilization procedures, use of sterile media and equipment, and adherence to aseptic techniques.

4. Explain the use of sampling and testing in fermentation processes.

Sampling and testing are essential for:

- Monitoring cell growth, metabolite production, and other process parameters.

- Evaluating product quality and ensuring compliance with specifications.

- Detecting potential contamination or deviations from optimal conditions.

- Providing data for process optimization and troubleshooting.

5. Describe the role of troubleshooting in maintaining efficient fermentation processes.

Troubleshooting is crucial for:

- Identifying and resolving deviations from expected process parameters.

- Minimizing downtime and maintaining process stability.

- Implementing corrective actions to prevent future issues.

- Ensuring product quality and compliance with regulatory requirements.

6. Explain the importance of following established protocols and regulatory guidelines in fermentation operations.

Adherence to protocols and guidelines is essential for:

- Ensuring consistent and reproducible fermentation processes.

- Maintaining product quality and safety.

- Meeting regulatory requirements and industry standards.

- Minimizing risks and liability.

7. Describe your experience in calibrating and maintaining fermentation equipment.

I have experience in calibrating and maintaining fermentation equipment, including:

- Temperature probes to ensure accurate temperature control.

- pH electrodes to monitor and adjust pH levels.

- Dissolved oxygen probes to optimize oxygen supply for cell growth.

- Agitation systems to maintain proper mixing and cell suspension.

- Harvesting equipment (e.g., centrifuges, filters) to separate cells and products.

8. Discuss your understanding of the principles of bioreactor design and operation.

I understand the principles of bioreactor design and operation, including:

- Different types of bioreactors (e.g., stirred tank, airlift, fluidized bed) and their applications.

- Factors affecting bioreactor performance (e.g., mass transfer, heat transfer, mixing).

- Design considerations (e.g., vessel geometry, materials of construction, instrumentation).

- Process parameters and their impact on cell growth and product formation.

9. Explain your experience in managing multiple fermentation runs simultaneously.

I have experience in managing multiple fermentation runs simultaneously, ensuring:

- Optimal conditions for each run by monitoring and adjusting process parameters.

- Efficient use of resources (e.g., media, equipment, staff).

- Coordination with other team members and departments.

- Prioritization of tasks and effective time management.

10. Describe your approach to working in a team environment within a fermentation facility.

In a team environment, I contribute by:

- Collaborating with colleagues to share knowledge and expertise.

- Communicating effectively to ensure clear understanding of tasks and responsibilities.

- Supporting other team members and providing assistance when needed.

- Maintaining a positive and professional attitude.

- Adhering to safety protocols and contributing to a safe work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fermentation Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fermentation Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Fermentation Operator is accountable for various critical tasks in the production process. Their responsibilities include:1. Process Monitoring and Control

Monitoring and controlling fermentation processes to ensure optimal conditions for microorganism growth

- Adjusting process parameters (e.g., temperature, pH, dissolved oxygen)

- Evaluating process data and making necessary adjustments to maintain process efficiency

2. Equipment Maintenance and Sanitation

Maintaining and cleaning fermentation equipment to prevent contamination and ensure process reliability

- Performing regular equipment inspections and preventive maintenance

- Cleaning and sterilizing equipment according to established protocols

3. Sample Collection and Analysis

Collecting and analyzing samples to monitor fermentation progress and ensure product quality

- Conducting various tests (e.g., cell counts, metabolite analysis)

- Interpreting results and making recommendations for process adjustments

4. Troubleshooting and Problem Solving

Identifying and resolving operational issues to ensure smooth production

- Analyzing process data and identifying potential problems

- Implementing corrective actions to minimize downtime and maintain process efficiency

Interview Tips

To ace an interview for a Fermentation Operator position, candidates should:1. Research the Company and Industry

Become familiar with the company’s products, market position, and industry trends

- Visit the company website and review their annual reports

- Read industry publications and news articles to gain insights into the company’s operations

2. Prepare for Technical Questions

Study basic concepts of fermentation technology, including microbial growth, bioreactor design, and process control

- Review your academic coursework or take online courses to brush up on your knowledge

- Practice answering common interview questions related to fermentation

3. Highlight Your Experience

Emphasize your relevant skills and experience in a clear and concise manner

- Quantify your achievements and provide specific examples of your contributions

- Tailor your responses to the specific requirements of the job description

4. Show Your Passion and Enthusiasm

Convey your interest and enthusiasm for the field of fermentation technology

- Express your understanding of the importance of fermentation in various industries

- Discuss your interest in pursuing professional development and staying updated on industry advancements

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fermentation Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!