Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Flavoring Oil Filterer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

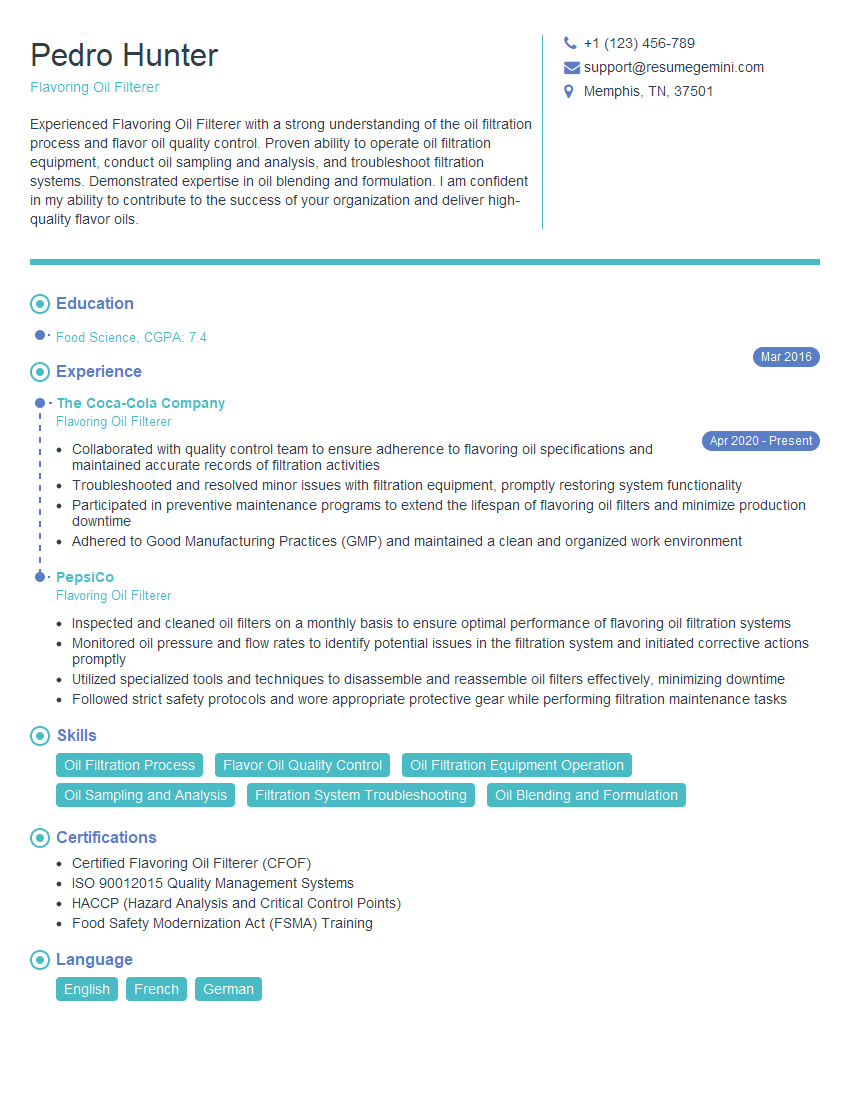

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flavoring Oil Filterer

1. Describe the process of flavoring oil filtration.

- The process of flavoring oil filtration involves removing impurities and contaminants from the oil while preserving its flavor and aroma.

- It typically involves several stages, including pre-filtration, main filtration, and post-filtration.

- Pre-filtration removes larger particles, such as sediment and debris, using a coarse filter.

- Main filtration removes finer particles and contaminants using a finer filter, such as a depth filter or membrane filter.

- Post-filtration may involve polishing the oil to remove any remaining impurities or to further enhance its flavor and clarity.

2. What are the different types of filters used in flavoring oil filtration?

Types of Filters

- Depth filters: Made of materials like cellulose or synthetic fibers, they trap particles throughout their depth, providing high dirt-holding capacity.

- Surface filters: Made of materials like metal or cloth, they capture particles on their surface, offering low pressure drop and high flow rates.

- Membrane filters: Made of fine polymeric materials, they remove extremely small particles and microorganisms, providing absolute filtration.

Selection Criteria

- Particle size and characteristics of contaminants

- Flow rate and pressure drop requirements

- Compatibility with the oil and flavorings

3. How do you ensure that the filtered oil meets the desired flavor profile?

- Closely follow standardized filtration protocols and quality control measures.

- Regularly monitor and analyze the oil throughout the filtration process using sensory evaluation, gas chromatography, or other analytical techniques.

- Collaborate with flavorists or sensory experts to determine the optimal filtration parameters and ensure that the desired flavor profile is achieved.

- Maintain precise control over filtration parameters such as temperature, pressure, and flow rate to minimize flavor loss or alteration.

4. What are the common problems encountered during flavoring oil filtration and how do you troubleshoot them?

- Clogging of filters: Increase filter capacity, adjust filtration parameters, or use pre-filters to reduce the load on main filters.

- Flavor loss or alteration: Optimize filtration parameters, use compatible filter materials, and minimize exposure to oxygen or other factors that can affect flavor.

- Microbial growth: Implement proper sanitation practices, use sterile filters, and maintain appropriate storage conditions to prevent contamination.

- Leaks or pressure drop issues: Inspect and maintain equipment regularly, ensure proper filter installation, and adjust pressure settings as needed.

5. What are the safety precautions that must be taken when working with flavoring oils?

- Wear appropriate personal protective equipment, including gloves, safety glasses, and respirators if necessary.

- Handle flavoring oils in well-ventilated areas to avoid inhalation of fumes.

- Store flavoring oils in properly labeled and sealed containers to prevent spills and contamination.

- Follow established safety protocols for handling flammable or hazardous materials, as some flavoring oils may contain volatile or combustible components.

6. How do you maintain and calibrate the equipment used in flavoring oil filtration?

- Follow manufacturer’s instructions for regular maintenance, including cleaning, lubrication, and filter replacement.

- Calibrate measuring and monitoring devices, such as pressure gauges and flow meters, to ensure accurate readings.

- Keep a maintenance log to document inspections, calibrations, and any repairs or adjustments made.

- Work with qualified technicians or equipment suppliers for major repairs or upgrades.

7. How do you optimize the efficiency and cost-effectiveness of flavoring oil filtration operations?

- Use efficient filtration equipment and optimize filtration parameters to minimize energy consumption and waste.

- Implement preventive maintenance programs to extend equipment life and reduce downtime.

- Negotiate favorable terms with suppliers for filters and other consumables.

- Explore opportunities for recycling or reusing spent filters or oil byproducts.

8. What are the latest advancements in flavoring oil filtration technology?

- Membrane filtration: Advanced membrane materials and configurations offer improved particle removal and flavor preservation.

- Nanofiltration: Can selectively remove specific contaminants or enhance flavor profiles by separating molecules based on size and charge.

- Ultrasonic filtration: Uses ultrasonic waves to enhance particle removal and improve filter cleaning efficiency.

- Automated filtration systems: Integrate sensors, control systems, and data analytics for real-time monitoring and optimization.

9. How do you stay updated on best practices and advancements in the flavoring oil filtration industry?

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Network with other professionals in the field.

- Participate in online forums and webinars.

10. What are your career goals and aspirations in the flavoring oil filtration industry?

- To become a highly skilled and knowledgeable flavoring oil filtration specialist.

- To contribute to the development and implementation of innovative filtration solutions that enhance flavor quality and efficiency.

- To assume leadership roles in the industry, sharing my expertise and driving advancements.

- To stay abreast of emerging technologies and best practices, continuously improving my skills and knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flavoring Oil Filterer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flavoring Oil Filterer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Flavoring Oil Filterer is responsible for ensuring the quality and purity of flavoring oils used in a variety of food and beverage products. Their primary duties include:

1. Filtration and Purification

Operate and maintain filtration equipment to remove impurities, contaminants, and unwanted solids from flavoring oils.

- Monitor filtration processes to ensure optimal performance and product quality.

- Identify and troubleshoot filtration issues promptly.

2. Quality Control and Testing

Conduct quality control tests on flavoring oils to verify their purity, concentration, and sensory properties.

- Use analytical instruments and techniques to assess flavor, aroma, and other quality parameters.

- Document and report test results to ensure compliance with quality standards.

3. Equipment Maintenance and Sanitation

Maintain and clean filtration equipment, workstations, and related tools to ensure proper functioning and hygiene.

- Follow established sanitation procedures to prevent contamination and ensure product safety.

- Inspect and calibrate equipment regularly to maintain accuracy and reliability.

4. Safety and Compliance

Adhere to safety protocols, regulations, and guidelines related to handling and filtering flavoring oils.

- Wear appropriate personal protective equipment (PPE).

- Dispose of waste materials properly and follow environmental regulations.

Interview Tips

To ace an interview for a Flavoring Oil Filterer position, it is important to highlight your relevant skills and experience. Here are some preparation tips to help you stand out.

1. Research the Company and Industry

Familiarize yourself with the company’s products, operations, and reputation. Research the flavoring oil industry to understand the market trends and technologies.

- Visit the company website and read industry publications.

- Network with individuals in the field to gain insights and learn about potential job openings.

2. Quantify Your Accomplishments

When describing your experience, use specific examples and quantifiable results to demonstrate your abilities. For instance, mention the amount of oil filtered, the reduction in impurities achieved, or the improvements in product quality you contributed to.

- For example, “Managed a team of 5 filter operators, resulting in a 20% increase in oil filtration capacity.”

- Or, “Developed and implemented a new filtration technique that reduced impurities by 35%, improving product quality and customer satisfaction.”

3. Emphasize Safety and Quality Control

Highlight your commitment to safety and quality assurance. Discuss your knowledge of industry regulations and standards, and your experience in implementing and maintaining quality control procedures.

- Mention your experience in using analytical instruments, such as gas chromatography or sensory analysis, to assess product quality.

- Explain how you ensure the proper handling, storage, and disposal of flavoring oils.

4. Demonstrate Problem-Solving Abilities

Flavoring Oil Filterers often encounter unexpected challenges. Showcase your problem-solving abilities by providing examples of how you troubleshoot filtration issues, optimize processes, or resolve quality concerns.

- For example, “Encountered a filtration blockage and quickly diagnosed the issue as a faulty pump. Replaced the pump, resolved the blockage, and resumed production with minimal downtime.”

- Or, “Identified a discrepancy in flavor profile and traced it back to a supplier issue. Collaborated with the supplier to rectify the problem and ensure product quality.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Flavoring Oil Filterer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!