Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Iron Launder Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

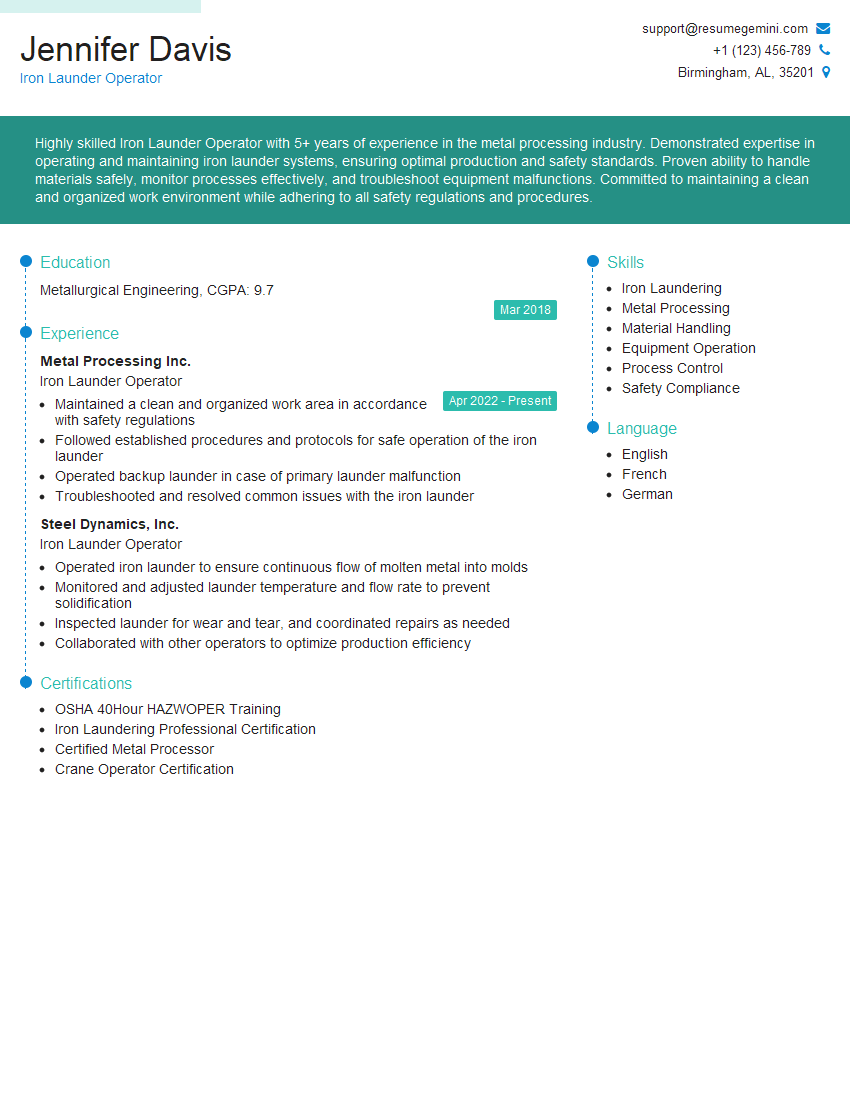

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Iron Launder Operator

1. What are the key responsibilities of an Iron Launder Operator?

The key responsibilities of an Iron Launder Operator include:

- Operating and maintaining industrial laundering equipment, such as ironers, folders, extractors, and dryers.

- Ensuring that all outgoing linen meets quality standards and specifications.

- Loading and unloading laundry items, and ensuring that they are processed according to established procedures.

- Monitoring equipment performance and identifying any potential problems.

- Maintaining a clean and organized work area.

2. What are the different types of industrial laundering equipment that you have experience with?

- Flatwork ironers

- Tunnel ironers

- Hemming machines

- Folders

- Extractors

- Dryers

3. How do you ensure that outgoing linen meets quality standards and specifications?

I ensure that outgoing linen meets quality standards and specifications by:

- Inspecting all linen items before they are released.

- Checking for any stains, tears, or other defects.

- Ensuring that all linen items are folded and packaged according to established procedures.

- Working closely with the quality control department to identify and resolve any quality issues.

4. What are some of the common problems that you have encountered when operating industrial laundering equipment?

Mechanical problems:

- Equipment breakdowns

- Malfunctioning sensors

- Electrical problems

Process problems:

- Wrinkling or creasing of linen

- Linen shrinkage

- Color fading

5. How do you troubleshoot and resolve problems with industrial laundering equipment?

I troubleshoot and resolve problems with industrial laundering equipment by:

- Identifying the source of the problem.

- Consulting with the equipment manufacturer or service technician.

- Performing necessary repairs or adjustments.

- Testing the equipment to ensure that it is functioning properly.

6. What are the safety procedures that you follow when operating industrial laundering equipment?

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Following all lockout/tagout procedures.

- Never reaching into moving machinery.

- Being aware of your surroundings and potential hazards.

- Reporting any safety concerns to your supervisor immediately.

7. What is your experience with working in a team environment?

I have extensive experience working in a team environment. I am able to work independently and as part of a team to achieve common goals. I am also able to communicate effectively with my team members and supervisors.

8. What are your strengths and weaknesses as an Iron Launder Operator?

Strengths:

- Attention to detail

- Mechanical aptitude

- Problem-solving skills

- Teamwork skills

Weaknesses:

- Can be impatient at times

- Sometimes have difficulty working under pressure

9. Why are you interested in working as an Iron Launder Operator for our company?

I am interested in working as an Iron Launder Operator for your company because I am passionate about the laundry industry. I have always been fascinated by the process of cleaning and ironing clothes, and I believe that I have the skills and experience necessary to be successful in this role. I am also excited about the opportunity to work for a company that is committed to providing high-quality laundry services to its customers.

10. What are your salary expectations?

My salary expectations are in line with the industry average for Iron Launder Operators with my experience and qualifications. I am willing to negotiate a salary that is fair and commensurate with my value to your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Iron Launder Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Iron Launder Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Iron Launder Operator is responsible for operating and maintaining iron laundering equipment in a steel mill. Their primary objective is to ensure that the molten iron produced by the blast furnace is properly cleaned and desulfurized before being sent to the steelmaking process.

1. Equipment Operation

Operate and control iron laundering equipment, including desulfurization stations, slag granulation systems, and ladle handling equipment.

- Monitor equipment performance and make necessary adjustments to maintain optimal operating conditions.

- Troubleshoot and resolve equipment malfunctions promptly.

2. Iron Laundering Process

Manage the iron laundering process, including desulfurization, slag removal, and temperature control.

- Add desulfurization agents to molten iron to remove sulfur impurities.

- Control the flow of molten iron and slag to ensure proper separation and removal.

- Maintain desired iron temperature throughout the laundering process.

3. Quality Control

Monitor and ensure the quality of molten iron before it is sent to steelmaking.

- Take samples of molten iron and conduct laboratory tests to analyze its composition and properties.

- Make adjustments to the laundering process based on test results to meet quality specifications.

4. Safety and Environment

Comply with all safety regulations and environmental standards related to iron laundering operations.

- Maintain a clean and organized work area to prevent accidents and spills.

- Monitor emissions and wastewater discharges to ensure compliance with environmental regulations.

Interview Tips

Preparing thoroughly for an iron launder operator interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and the Role

Before the interview, take the time to learn about the company you’re applying to and the specific role you’re interviewing for. This will help you understand the company’s culture, values, and the requirements of the position.

- Visit the company’s website to gather information about their history, products/services, and industry standing.

- Read industry publications and news articles to stay up-to-date on the latest trends and best practices.

2. Practice Your Answers

Take some time to think about the common interview questions you’re likely to face and prepare your answers in advance. This will help you deliver confident and well-structured responses during the interview.

- Prepare for questions about your experience, skills, and qualifications.

- Consider questions related to your knowledge of iron laundering processes and equipment.

3. Highlight Your Skills and Experience

During the interview, focus on showcasing your relevant skills and experience that align with the requirements of the role. Use specific examples to demonstrate your abilities.

- Emphasize your experience in operating and maintaining iron laundering equipment.

- Highlight your knowledge of desulfurization and slag removal processes.

- Provide examples of how you have ensured quality control and compliance in previous roles.

4. Ask Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role and the company. Prepare a few questions to ask the interviewer, such as:

- What are the biggest challenges facing the iron and steel industry today?

- What are the company’s plans for future growth and innovation in the iron laundering process?

- What opportunities are there for professional development and advancement within the company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Iron Launder Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!