Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Malt House Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

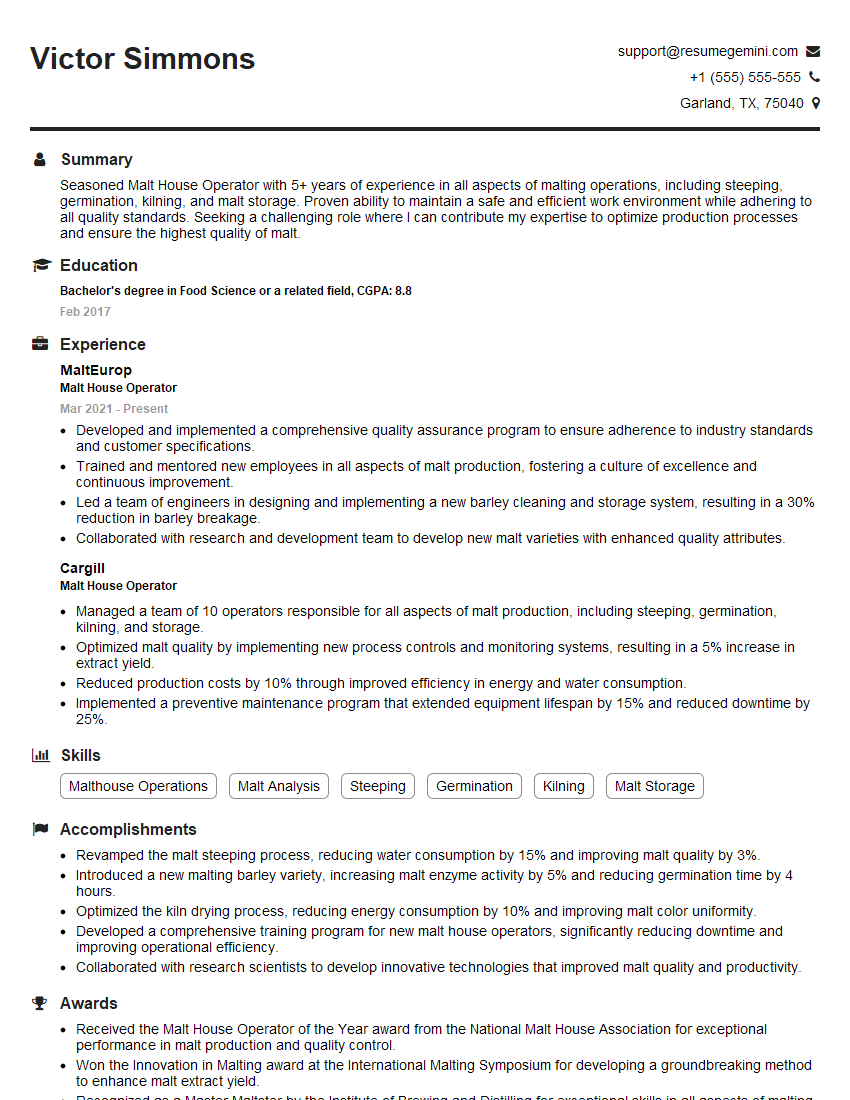

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Malt House Operator

1. Describe the different stages involved in the malting process?

The malting process involves several stages, including:

- Steeping: Barley grains are soaked in water to initiate germination.

- Germination: The grains are spread out on a germination floor, where they are kept moist and warm to encourage root and shoot growth.

- Kilning: The germinated grains are dried in a kiln using warm air to stop germination and develop the desired flavors and enzymes.

- Cleaning: The finished malt is cleaned to remove any debris or damaged kernels.

2. What are the critical quality parameters to consider when assessing the quality of malt?

- Moisture content: The malt should have an appropriate moisture content for proper storage and use.

- Extract yield: The extract yield indicates the amount of fermentable sugars present in the malt.

- Friability: The malt should be friable, meaning it should break easily into small pieces without excessive dust or fines.

- Diastatic power: The diastatic power measures the enzymatic activity of the malt, indicating its ability to convert starches into fermentable sugars.

- Flavor and aroma: The malt should have the desired flavor and aroma characteristics for the intended beer style.

3. How do you monitor and control the temperature and humidity during the germination process?

Monitoring and controlling temperature and humidity during germination is crucial to ensure optimal rootlet growth. I use temperature sensors and humidity gauges to continuously track these parameters.

To control temperature, I adjust the airflow and use cooling equipment as needed. For humidity control, I regulate the water supply and use humidifiers or dehumidifiers to maintain the desired levels.

4. What are the common problems that can occur during the malting process and how do you troubleshoot them?

- Over-steeping: This can lead to excessive root growth and potential mold issues. I adjust steeping time and water temperature to prevent this.

- Under-germination: This can result in poor enzymatic activity. I ensure proper temperature and moisture conditions during germination to promote optimal growth.

- Kiln problems: Uneven drying or excessive heat can impact malt quality. I closely monitor kiln temperature and airflow to ensure proper drying.

- Mold growth: This can occur due to excessive moisture or contamination. I maintain proper hygiene, control humidity, and use antifungal agents if necessary.

5. What is the role of enzymes in the malting process?

Enzymes play a crucial role in malting by breaking down complex compounds in barley into fermentable sugars and other components.

- Alpha-amylase: Converts starch into fermentable sugars.

- Beta-amylase: Converts starch into maltose.

- Proteases: Degrade proteins into amino acids.

- Lipases: Break down lipids into fatty acids.

6. How do you ensure the safety and hygiene of the malt house?

Maintaining safety and hygiene is paramount in a malt house to prevent contamination and ensure product quality.

- Regular cleaning and sanitation: Implement a comprehensive cleaning and sanitation program for all equipment and surfaces.

- Pest control: Establish a pest control plan to prevent insects, rodents, and other pests from entering the facility.

- Employee training: Train employees on proper hygiene practices and the importance of maintaining a clean work environment.

- Personal protective equipment: Require employees to wear appropriate personal protective equipment, such as gloves, hair nets, and safety glasses.

7. How do you optimize the efficiency of the malting process?

- Monitor and control process parameters: Track key parameters such as temperature, humidity, and airflow throughout the process to identify areas for improvement.

- Implement automation: Utilize automation technologies to control equipment and minimize manual labor, leading to increased efficiency.

- Use efficient steeping and germination systems: Employ innovative steeping and germination systems to maximize extract yield and reduce water consumption.

- Optimize kiln operations: Monitor and regulate kiln temperature and airflow to achieve optimal drying efficiency and reduce energy consumption.

8. What are the different types of malt used in brewing, and how do they impact the final beer?

- Pale malt: Used in a wide range of beers, providing a neutral flavor base and moderate fermentability.

- Pilsner malt: Known for its light color and crisp, refreshing flavor, often used in lagers.

- Munich malt: Imparts a slightly sweet and caramel-like flavor, commonly found in amber and dark beers.

- Roasted malt: Provides a dark color and roasted flavors, adding complexity to stouts and porters.

- Crystal malt: Adds sweetness, caramel flavors, and a reddish hue to beers.

9. Describe your experience in quality control for malt production.

Throughout my career, quality control has been integral to my role as a Malt House Operator. I have implemented:

- Regular malt analysis to assess parameters like moisture content, extract yield, and diastatic power.

- Sensory evaluations to ensure the malt meets the desired flavor and aroma profile.

- Established quality control protocols to monitor all stages of the malting process and identify potential issues.

- Taken corrective actions promptly to address any non-conformances and maintain product quality.

10. Tell me about your experience in maintaining and troubleshooting malt house equipment.

- Regularly inspected and maintained all equipment, including steep tanks, germination floors, and kilns.

- Troubleshooted and repaired equipment malfunctions, ensuring minimal downtime and optimal production.

- Collaborated with maintenance technicians to perform major repairs and upgrades.

- Developed preventative maintenance plans to minimize equipment issues and extend the lifespan of assets.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Malt House Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Malt House Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Malt House Operators are responsible for overseeing the production of malt, which is a key ingredient in beer, whiskey, and other alcoholic beverages. They ensure that the malting process is carried out efficiently and safely, and that the malt produced meets the required quality standards.

1. Operating and Maintaining Malting Equipment

Operate and maintain malting equipment, including soaking tanks, germination chambers, kilns, and milling machines.

- Monitor and adjust equipment settings to ensure optimal malting conditions.

- Perform routine maintenance and repairs to keep equipment in good working order.

2. Managing the Malting Process

Manage the malting process from start to finish, including steeping, germination, kilning, and cooling.

- Monitor and control the temperature, humidity, and airflow during each stage of the process.

- Conduct quality checks and make adjustments as needed to ensure the malt meets specifications.

3. Ensuring Product Quality

Ensure the quality of the malt produced by conducting regular tests and inspections.

- Analyze malt samples for moisture content, protein content, and enzymatic activity.

- Identify and resolve any quality issues that may arise during the malting process.

4. Maintaining a Safe and Clean Work Environment

Maintain a safe and clean work environment by adhering to all safety regulations and procedures.

- Wear appropriate personal protective equipment (PPE) when operating equipment.

- Clean and disinfect work areas regularly to prevent contamination.

Interview Tips

Preparing for an interview can be daunting, but with the right approach, you can increase your chances of success. Here are some tips to help you ace your interview for a Malt House Operator position:

1. Research the Company and Position

Take the time to learn about the company you are applying to and the specific position you are interested in. This will help you understand the company’s culture, goals, and expectations for the role.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Highlight Your Skills and Experience

Be sure to highlight your skills and experience that are relevant to the position you are applying for. For example, if you have experience operating malting equipment or managing the malting process, be sure to mention this in your interview.

4. Be Prepared to Ask Questions

Asking questions at the end of an interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the role and the organization.

5. Dress Professionally and Arrive on Time

First impressions matter, so be sure to dress professionally for your interview and arrive on time. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

Next Step:

Now that you’re armed with the knowledge of Malt House Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Malt House Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini