Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mash Processing Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

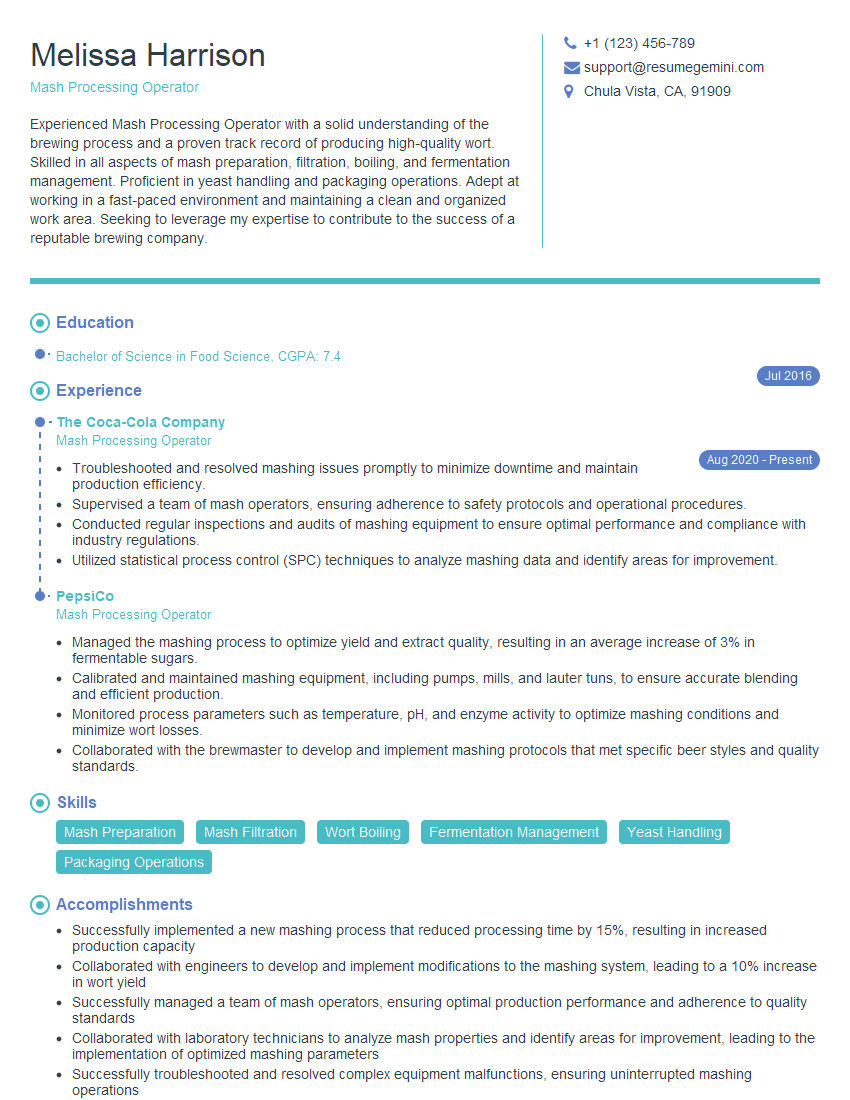

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mash Processing Operator

1. Describe the key responsibilities of a Mash Processing Operator?

As a Mash Processing Operator, I am responsible for the following key tasks:

- Operate and maintain the mash processing equipment, including the mash tun, lauter tun, and wort boiler

- Monitor and control the mashing process, including temperature, pH, and enzyme activity

- Take samples of the mash and wort at various stages of the process for quality control

- Clean and sanitize the equipment after each use

- Follow safety procedures and regulations

2. What are the different types of mashing processes?

There are two main types of mashing processes:

- Infusion mashing: In this method, the malt is added to the hot water all at once and the temperature is held constant for a period of time

- Decoction mashing: In this method, the malt is added to the hot water in stages and the temperature is varied throughout the process

3. What are the key factors that affect the efficiency of the mashing process?

The key factors that affect the efficiency of the mashing process include:

- The type of malt used

- The grind size of the malt

- The temperature of the mash

- The pH of the mash

- The enzyme activity

- The length of the mash

4. How do you troubleshoot common problems that occur during the mashing process?

Some common problems that occur during the mashing process include:

- Stuck mash: This can be caused by a number of factors, including incorrect grind size, incorrect temperature, or incorrect pH

- Wort haze: This can be caused by a number of factors, including the presence of proteins or lipids in the wort

- Wort bitterness: This can be caused by the presence of tannins in the wort

5. What are the safety procedures that must be followed when operating mash processing equipment?

The following safety procedures must be followed when operating mash processing equipment:

- Wear appropriate personal protective equipment, including gloves, safety glasses, and a hard hat

- Do not operate the equipment if you are not trained and authorized to do so

- Keep the equipment clean and free of debris

- Follow the manufacturer’s instructions for operating the equipment

- Never reach into the equipment while it is operating

- Report any accidents or injuries to your supervisor immediately

6. What are the quality control procedures that must be followed when producing mash?

The following quality control procedures must be followed when producing mash:

- Take samples of the mash at various stages of the process and test them for pH, temperature, and enzyme activity

- Monitor the mash for any signs of contamination

- Keep records of all quality control tests

- Follow the manufacturer’s specifications for the mash

7. What are the key differences between mashing for beer and mashing for whiskey?

The key differences between mashing for beer and mashing for whiskey are:

- The type of malt used: Beer is typically made from barley malt, while whiskey can be made from a variety of grains, including corn, rye, and wheat

- The grind size of the malt: The malt is ground more finely for beer than for whiskey

- The temperature of the mash: The mash is heated to a higher temperature for beer than for whiskey

- The length of the mash: The mash is held for a longer period of time for beer than for whiskey

8. What are the different types of enzymes that are used in the mashing process?

The following enzymes are used in the mashing process:

- Alpha-amylase: This enzyme breaks down starch into dextrins

- Beta-amylase: This enzyme breaks down dextrins into maltose

- Glucoamylase: This enzyme breaks down maltose into glucose

9. What is the role of pH in the mashing process?

The pH of the mash affects the activity of the enzymes that are used in the mashing process. The optimal pH for mashing is between 5.2 and 5.6.

10. What is the role of temperature in the mashing process?

The temperature of the mash affects the activity of the enzymes that are used in the mashing process. The optimal temperature for mashing is between 62°C and 72°C.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mash Processing Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mash Processing Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Mash Processing Operator is an integral part of the beverage production process, tasked with ensuring the efficient and consistent operation of mashing equipment. Their primary responsibilities include:

1. Mash Preparation and Operation

Involves preparing mash bills, selecting and weighing grains, and adjusting water chemistry to achieve desired mash characteristics.

- Calculates mash recipes based on production specifications

- Operates mashing and lautering equipment to extract sugars from grains

2. Equipment Maintenance and Calibration

Ensuring proper functioning of mashing systems by conducting regular inspections, cleaning, and calibration.

- Performs preventive maintenance and repairs on mashing equipment

- Calibrates temperature sensors, flow meters, and other instrumentation

3. Quality Control and Analysis

Monitoring mash pH, temperature, and other parameters to ensure adherence to quality standards.

- Conducts sensory and analytical tests on mash samples

- Adjusts process parameters based on quality control data

4. Safety and Sanitation

Adhering to established safety protocols, ensuring a clean and hygienic work environment.

- Follows all safety procedures and wears appropriate personal protective equipment

- Maintains a sanitary work area and follows good manufacturing practices

Interview Tips

To ace the interview for a Mash Processing Operator position, follow these key tips:

1. Research the Company and Role

Demonstrate your enthusiasm for the position by researching the company, their products, and the specific responsibilities of the role. This shows that you are well-prepared and genuinely interested in the opportunity.

- Visit the company website, read industry news, and connect with current employees on LinkedIn.

- Thoroughly review the job description and highlight your relevant skills and experience.

2. Emphasize Your Technical Skills

Highlight your proficiency in mashing operations, including experience with different types of mashing systems, grain handling techniques, and quality control procedures. Provide specific examples of your technical abilities and how they have contributed to the success of previous projects.

- Describe your experience in preparing and operating mashing equipment.

- Quantify your results, such as improvements in efficiency or reduction in waste.

3. Demonstrate Your Problem-Solving Abilities

Interviewers want to know that you can think critically and solve problems effectively. Share examples of challenges you have encountered in your previous roles and explain how you overcame them. Emphasize your analytical skills and ability to work under pressure.

- Recall a situation where you identified a problem in the mashing process and developed a solution.

- Explain your decision-making process and how your actions led to a positive outcome.

4. Highlight Your Safety Awareness and Attention to Detail

Safety and sanitation are paramount in the beverage industry. Emphasize your commitment to following safety protocols and maintaining a clean work environment. Additionally, demonstrate your attention to detail and ability to perform tasks with precision and accuracy.

- Describe your experience in adhering to safety regulations and maintaining a sanitary workplace.

- Provide examples of how your attention to detail has contributed to quality control and process optimization.

Next Step:

Now that you’re armed with the knowledge of Mash Processing Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mash Processing Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini