Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Plasma Processing Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

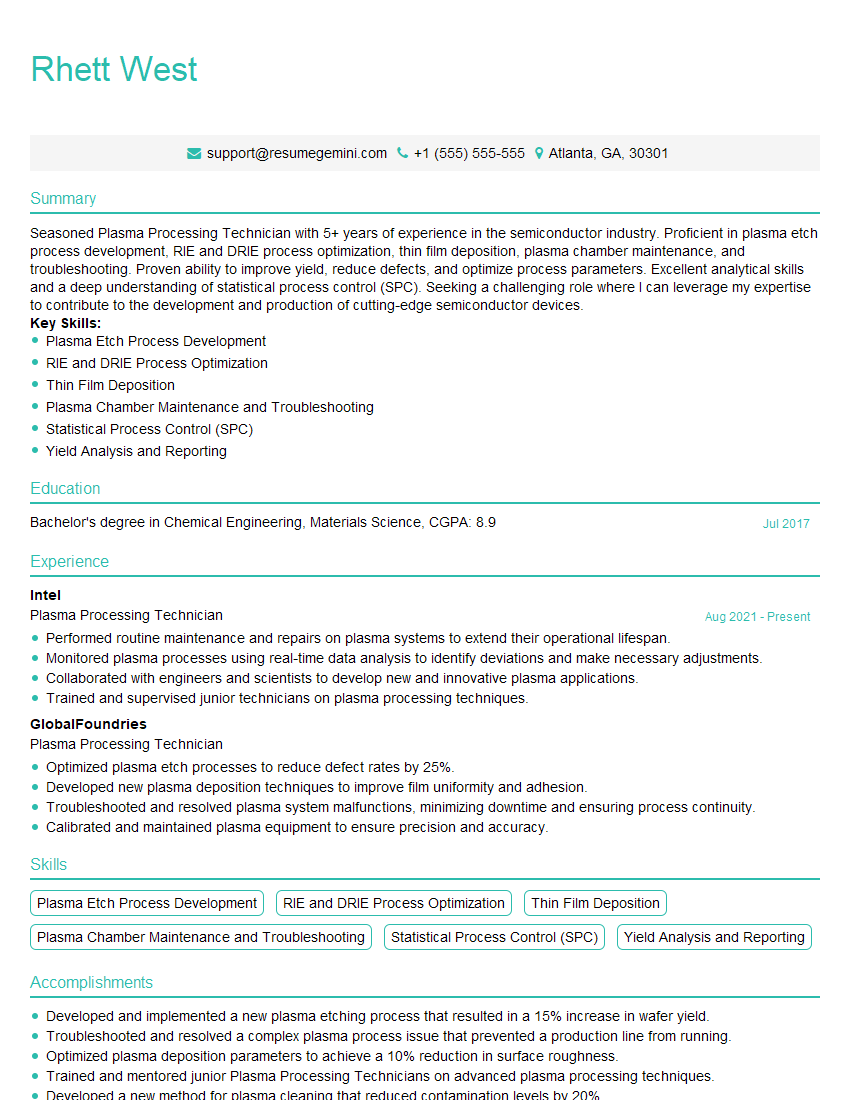

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plasma Processing Technician

1. Describe the fundamental principles of plasma processing.

Plasma processing is a technique that employs a plasma, which is an ionized gas, to modify or treat materials. Here’s a breakdown of its fundamental principles:

- Creation of Plasma: Plasma is generated by energizing a gas through various means, such as radio frequency (RF) waves or microwave radiation. This process causes atoms to lose their electrons, creating a mixture of positively charged ions and negatively charged electrons, known as a plasma.

- Plasma-Material Interaction: The plasma interacts with the target material in different ways depending on the process parameters. Plasma can etch, deposit, or modify the surface of the material by transferring energy, ions, or reactive species to it.

- Plasma-Induced Reactions: Plasma can trigger chemical reactions at the material’s surface. These reactions can etch, deposit, or modify the material’s chemical composition and properties.

- Plasma Process Control: Plasma processing involves controlling various parameters such as gas type, pressure, power, and temperature to achieve specific results. Monitoring and feedback systems are used to maintain these parameters within desired ranges.

2. Explain the different types of plasma processing techniques.

Plasma Etching

- Uses plasma to remove or shape materials by breaking down the chemical bonds on the surface.

- Employs gases such as oxygen, chlorine, or fluorine to react with the material.

Plasma Deposition

- Uses plasma to deposit a thin film of material onto a substrate.

- Involves introducing a precursor gas into the plasma, which decomposes and forms a solid film on the substrate.

Plasma Modification

- Uses plasma to alter the surface properties of materials without removing or depositing material.

- Can improve adhesion, wettability, or other surface characteristics.

3. Describe the role of pressure and temperature in plasma processing.

Pressure and temperature play critical roles in plasma processing:

- Pressure: Lower pressure results in a more uniform and isotropic plasma, while higher pressure promotes directional etching and deposition.

- Temperature: Higher temperature increases the energy of ions and electrons in the plasma, enhancing their reactivity with the material. It also affects the rate of chemical reactions and the properties of deposited films.

4. Explain the purpose of using gas mixtures in plasma processing.

Gas mixtures are used in plasma processing to achieve specific process outcomes:

- Etching: Mixtures of reactive gases (e.g., oxygen, chlorine, fluorine) are used to enhance etching rates and achieve desired surface morphologies.

- Deposition: Mixtures of precursor gases (e.g., silane, methane) and carrier gases (e.g., argon, helium) are used to control the composition and properties of deposited films.

- Modification: Mixtures of reactive and inert gases (e.g., oxygen, nitrogen) are used to modify surface properties such as wettability and adhesion.

5. Discuss the safety precautions that should be taken when working with plasma processing equipment.

Working with plasma processing equipment requires adherence to strict safety precautions to minimize risks:

- Electrical Safety: Equipment should be properly grounded and shielded to prevent electrical shocks.

- Gas Hazards: Toxic and corrosive gases used in processing must be handled and disposed of safely.

- Radiation Hazards: Plasma processes can generate harmful radiation, necessitating proper shielding and protective gear.

- Eye and Skin Protection: UV radiation and plasma emissions can cause eye and skin damage, so appropriate protective eyewear and clothing must be worn.

- Emergency Procedures: Personnel should be trained on proper emergency procedures in case of equipment malfunctions or accidents.

6. Describe the applications of plasma processing in the semiconductor industry.

Plasma processing plays a crucial role in the semiconductor industry:

- Wafer Cleaning: Plasma can remove contaminants and improve the surface quality of wafers.

- Etching: Plasma etching is used to create precise patterns and features in semiconductor devices.

- Deposition: Plasma deposition is employed to form thin films of materials, such as dielectric layers and metal interconnects.

- Modification: Plasma modification can enhance the surface properties of materials, improving adhesion and other characteristics.

7. Explain the principles of optical emission spectroscopy (OES) for plasma diagnostics.

Optical emission spectroscopy (OES) is a technique used to analyze the plasma composition and processes:

- Light Emission: Plasma species emit light at specific wavelengths when excited.

- OES Analysis: By measuring the intensity and wavelength of emitted light, the concentration, and excitation state of plasma species can be determined.

- Plasma Monitoring: OES provides real-time information about plasma parameters, enabling process control and optimization.

8. Discuss the common challenges and troubleshooting techniques in plasma processing.

Challenges

- Plasma Non-Uniformity: Ensuring uniform plasma distribution across the substrate can be challenging.

- Process Drift: Plasma parameters can drift over time, affecting process stability.

- Surface Damage: Plasma can damage the substrate surface if process parameters are not optimized.

Troubleshooting

- Plasma Characterization: Using OES or other diagnostics to analyze plasma parameters helps identify issues.

- Process Optimization: Adjusting process parameters such as pressure, temperature, and gas flow can address non-uniformity and drift.

- Equipment Maintenance: Regular maintenance and cleaning of equipment can prevent surface damage and ensure optimal performance.

9. Describe the recent advancements in plasma processing technology.

Plasma processing technology is constantly evolving:

- Atmospheric Pressure Plasma: Allows plasma processing at atmospheric pressure, opening new applications.

- Low-Damage Etching: Techniques like cryogenic plasma etching minimize surface damage during etching processes.

- Plasma-Assisted Deposition: Combining plasma with deposition techniques enhances film quality and deposition rate.

- Roll-to-Roll Processing: Continuous plasma processing for flexible substrates, enabling high-throughput manufacturing.

10. How do you stay updated with the latest developments in plasma processing?

To stay up-to-date with the latest advancements in plasma processing, I engage in the following practices:

- Attend Conferences and Workshops: Industry events provide valuable opportunities to learn about new technologies and connect with experts.

- Read Scientific Publications: Journals and conference proceedings offer insights into cutting-edge research and developments.

- Online Courses and Webinars: Educational platforms offer specialized courses and webinars on plasma processing.

- Collaborate with Researchers: Engaging with academia and research institutions exposes me to innovative ideas and advancements.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plasma Processing Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plasma Processing Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plasma Processing Technicians play a crucial role in the manufacturing of semiconductor devices, utilizing plasma techniques for various applications, especially in the etching and deposition processes.

1. Plasma Etch Process Operation

Operate and monitor plasma etch equipment in a cleanroom environment, ensuring precise control of process parameters to achieve desired etch results.

- Configure and maintain plasma etch systems, including selecting appropriate process recipes and optimizing process variables.

- Monitor plasma etch process in real-time, identify potential issues, and take corrective actions as needed.

- Conduct process testing and evaluation to verify etch quality and optimize process performance.

2. Plasma Deposition Process Operation

Operate and monitor plasma deposition equipment, controlling process parameters to achieve specified film properties.

- Load and unload wafers into plasma deposition systems, adhering to strict contamination prevention protocols.

- Maintain and troubleshoot plasma deposition equipment, ensuring optimal operation and minimizing downtime.

- Develop and optimize deposition processes, exploring new techniques to enhance film quality and meet evolving requirements.

3. Quality Control and Process Monitoring

Perform quality control inspections, including visual inspection and electrical testing, to evaluate the quality of processed wafers.

- Collect and analyze process data, identify trends, and suggest process improvements to enhance overall yield and quality.

- Troubleshoot process issues, implement corrective actions, and collaborate with engineers to resolve complex problems.

- Maintain detailed records of process operations and equipment maintenance for traceability and compliance.

4. Safety and Compliance

Adhere to strict safety protocols in a cleanroom environment, including proper handling of hazardous materials and use of personal protective equipment.

- Comply with all applicable regulations and industry standards related to plasma processing and semiconductor manufacturing.

- Promote a culture of safety and environmental awareness within the work area.

Interview Tips

To ace your interview for a Plasma Processing Technician position, follow these preparation tips and interview hacks:

1. Research the Company and Role

Thoroughly research the company and the specific role you’re applying for. Understand the company’s mission, products or services, and industry reputation.

- Visit the company’s website, read industry news, and check professional networking platforms like LinkedIn for insights.

- Carefully review the job description and identify the key skills and responsibilities required.

2. Highlight Your Technical Expertise

Showcase your strong understanding of plasma processing techniques, including etch and deposition processes. Quantify your experience with specific equipment and processes, providing details on the results you achieved.

- Discuss your experience in optimizing process parameters, troubleshooting equipment issues, and implementing quality control measures.

- If applicable, mention any certifications or specialized training you have received in plasma processing.

3. Emphasize Your Problem-Solving Skills

Interviewers will be impressed by candidates who can demonstrate strong problem-solving abilities. Highlight your experience in identifying and resolving process issues, proposing solutions, and working effectively in a team environment.

- Provide examples of specific instances where you successfully diagnosed and resolved complex problems with plasma processing equipment.

- Share your approach to troubleshooting and your ability to think critically and find innovative solutions.

4. Prepare Industry-Specific Questions

Impress the interviewers by asking thoughtful questions that show your knowledge of the plasma processing industry. This demonstrates your enthusiasm and willingness to learn.

- Ask about the company’s latest advancements in plasma processing technology or their approach to quality control.

- Inquire about the company’s plans for future product development or process optimization.

5. Practice Your Answers

Practice answering common interview questions related to plasma processing, such as those related to your technical skills, problem-solving abilities, and experience with specific equipment. This will help you deliver confident and articulate answers during the interview.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Practice speaking clearly and concisely, and be prepared to elaborate on your answers if requested.

Next Step:

Now that you’re armed with the knowledge of Plasma Processing Technician interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Plasma Processing Technician positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini