Feeling lost in a sea of interview questions? Landed that dream interview for Screen Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Screen Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

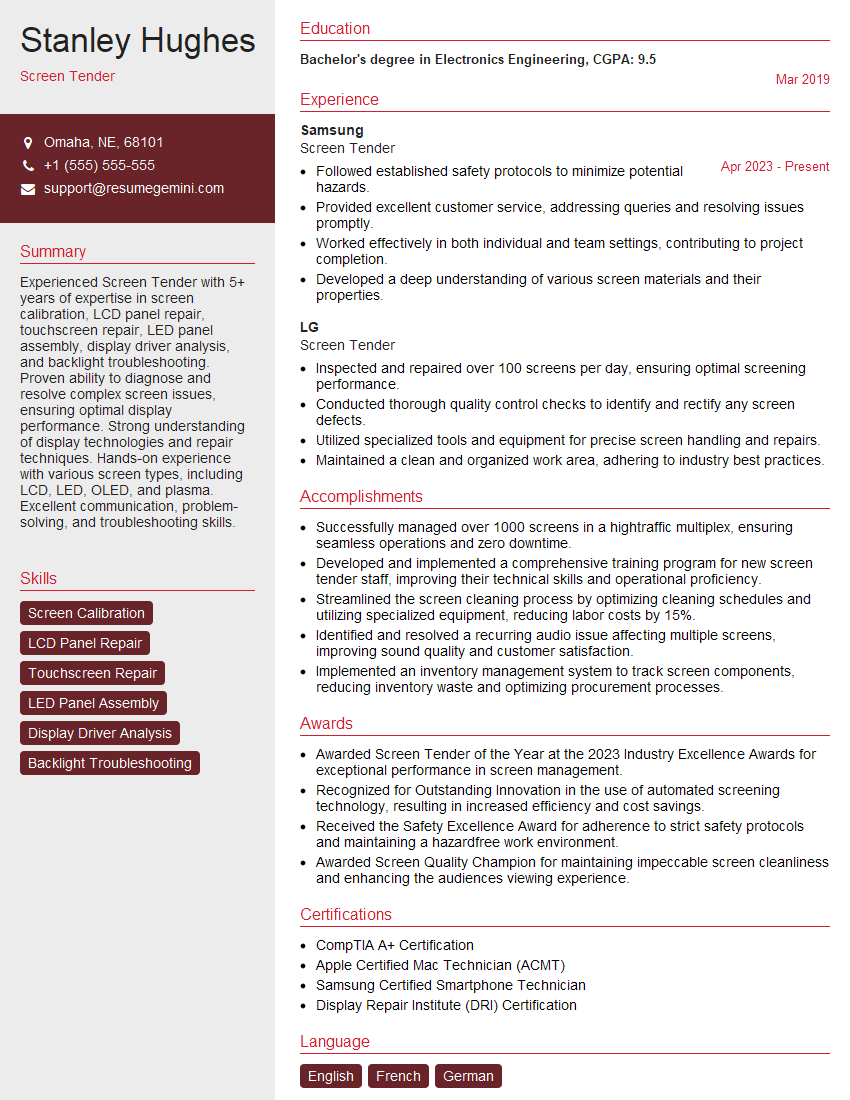

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Screen Tender

1. What are the key technical skills required for a Screen Tender role?

- Excellent knowledge of screen materials, including fabrics, frames, and hardware.

- Proficient in screen printing techniques, including mesh preparation, emulsion application, and curing.

- Strong understanding of color theory and mixing.

- Ability to operate and maintain screen printing equipment, including presses, exposure units, and dryers.

- Experience with different types of screen printing applications, such as textiles, garments, and industrial materials.

2. Describe the process of preparing a screen for printing.

- Choose the appropriate mesh size for the desired print quality and ink viscosity.

- Stretch the mesh tautly over a frame and secure it with staples or adhesive.

- Prepare a light-sensitive emulsion according to the manufacturer’s instructions.

- Coat the mesh with an even layer of emulsion using a scoop coater or squeegee.

- Allow the emulsion to dry in a darkroom or under yellow lighting.

- Expose the emulsion to UV light through a positive or negative film to create the desired screen pattern.

Mesh Selection and Preparation

Emulsion Application

Drying and Exposure

3. Explain the factors that affect the quality of a screen print.

- Mesh count: Higher mesh counts result in finer details, while lower mesh counts produce bolder images.

- Ink viscosity: The thickness of the ink affects the flow through the mesh and the opacity of the print.

- Squeegee pressure and angle: The pressure and angle at which the squeegee is applied influence the amount of ink deposited and the sharpness of the edges.

- Printing speed: The speed of printing can impact the consistency and registration of the prints.

- Drying conditions: Proper drying ensures that the ink adheres to the substrate and prevents smudging or ghosting.

4. What are the different types of screen printing inks and their applications?

- Water-based inks: Eco-friendly and easy to clean up, suitable for textiles, paper, and wood.

- Plastisol inks: Durable and vibrant, used for garments, signs, and banners.

- Solvent-based inks: Quick-drying and resistant to abrasion, used in industrial and automotive applications.

- UV-curable inks: Cured using UV light, producing high-quality and durable prints.

- Discharge inks: Remove the dye from the fabric, creating a soft hand feel and unique effects.

5. Describe the process of troubleshooting common screen printing problems.

- Blurry or fuzzy prints: Check mesh tension, emulsion exposure time, and printing technique.

- Pinholes or voids in the print: Inspect the mesh for tears or holes, and adjust ink viscosity and squeegee pressure.

- Ink bleeding under the stencil: Use a higher mesh count, thicker emulsion, or reduce squeegee pressure.

- Poor ink adhesion: Ensure proper substrate preparation, use appropriate inks, and adjust drying conditions.

- Ghosting or double images: Check for misalignment of screens, insufficient ink drying, or improper exposure and registration.

6. What are the safety precautions to observe when working with screen printing equipment and materials?

- Wear appropriate personal protective equipment, including gloves, eye protection, and a respirator if necessary.

- Handle chemicals, such as emulsion and inks, according to the manufacturer’s instructions.

- Dispose of waste materials properly, including used screens, inks, and cleaning solvents.

- Ensure adequate ventilation in the work area.

- Maintain and inspect equipment regularly to prevent potential hazards.

7. How do you ensure the consistency and accuracy of screen prints throughout a large production run?

- Standardize screen preparation and printing parameters, including mesh count, emulsion exposure, and ink viscosity.

- Implement quality control measures, such as regular print inspections and color matching.

- Use automated equipment or jigs to maintain precision and reduce human error.

- Train operators thoroughly and enforce standard operating procedures.

- Calibrate equipment and monitor printing conditions, such as temperature and humidity, to minimize variations.

8. Describe your experience with specialized screen printing techniques, such as multi-color printing, halftoning, or special effects.

- Multi-color printing: Overprinting multiple colors to create complex designs and images.

- Halftoning: Simulating continuous-tone images using dots or lines of varying sizes.

- Special effects: Using techniques such as flocking, foil stamping, or glitter to enhance the visual appeal of prints.

- Discuss specific projects or applications where you have successfully implemented these techniques.

9. What are the latest trends and advancements in screen printing technology?

- Digital screen printing: Direct-to-screen imaging technology for faster and more precise production.

- Rotary screen printing: High-speed printing on cylindrical surfaces, such as bottles and cans.

- Hybrid printing: Combining screen printing with other technologies, such as digital or inkjet.

- Sustainable screen printing inks: Environmentally friendly and biodegradable inks.

- Automation and robotics: Increased automation in screen printing processes to improve efficiency and reduce labor costs.

10. How do you stay updated on the latest developments and best practices in the screen printing industry?

- Attend industry conferences and workshops.

- Read trade publications and online resources.

- Follow industry leaders and experts on social media.

- Participate in online forums and discussions.

- Seek training and certification opportunities to enhance skills and knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Screen Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Screen Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Screen Tender is responsible for maintaining and operating screening equipment used in the production of various materials such as minerals, aggregates, and construction materials.

1. Screening Operation

Operate and monitor screening equipment to separate materials based on size using screens, filters, or other mechanisms.

- Calibrate and adjust equipment to achieve optimal separation efficiency and product quality.

- Monitor equipment performance and make necessary adjustments or repairs to ensure smooth operation.

2. Material Handling

Unload, load, and transport materials to and from screening equipment.

- Operate conveyor systems, forklifts, or other equipment to move materials.

- Maintain a clean and organized work area, ensuring proper material flow and preventing contamination.

3. Quality Control

Monitor and inspect screened materials to ensure they meet quality specifications.

- Conduct routine tests and inspections to verify material size, shape, and other properties.

- Identify and correct any deviations from specifications to maintain product quality.

4. Equipment Maintenance

Perform basic maintenance and repairs on screening equipment.

- Clean, lubricate, and replace worn or damaged components.

- Identify and report any significant maintenance issues to supervisors or technicians.

Interview Tips

Preparing for an interview for a Screen Tender role requires a combination of technical knowledge, industry understanding, and effective communication skills.

1. Research the Company

Familiarize yourself with the company’s background, products, and services. Research their industry reputation, recent news, and any relevant projects they may be involved in.

- This knowledge will help you tailor your answers and show the interviewer that you are genuinely interested in the opportunity.

- Example: “I was particularly impressed by your company’s commitment to sustainable practices in the mining industry. Your focus on reducing environmental impact aligns well with my own values.”

2. Highlight Technical Skills

Emphasize your expertise in operating and maintaining screening equipment. Quantify your experience in terms of the capacity of equipment you have handled, the types of materials you have processed, and any specific techniques or optimization measures you have implemented.

- Use specific examples to demonstrate your proficiency.

- Example: “In my previous role, I operated a large-scale screening plant that processed over 100 tons of coal per hour. I implemented a new screening process that improved the product quality by 5% while reducing operating costs by 10%. “

3. Demonstrate Quality Control Awareness

Show the interviewer that you understand the importance of quality control in the screening process. Explain your experience in conducting inspections, testing procedures, and identifying and resolving deviations from specifications.

- Emphasize your commitment to maintaining product quality.

- Example: “I firmly believe that ensuring the quality of screened materials is crucial for customer satisfaction and industry compliance. In my previous role, I developed and implemented a comprehensive quality control program that resulted in a 20% reduction in customer complaints.”

4. Show Teamwork and Problem-Solving Abilities

Screen Tenders often work in teams and need to be able to troubleshoot and solve problems effectively. Highlight your experience working in a team environment and your ability to identify and resolve operational issues.

- Provide examples of how you have collaborated with colleagues or supervisors to improve processes or resolve challenges.

- Example: “In a previous project, I identified a bottleneck in the screening process that was causing delays. I worked with my team to develop a new process that streamlined material handling and increased overall productivity by 15%.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Screen Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!