Are you gearing up for a career in Vacuum Pan Tender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Vacuum Pan Tender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

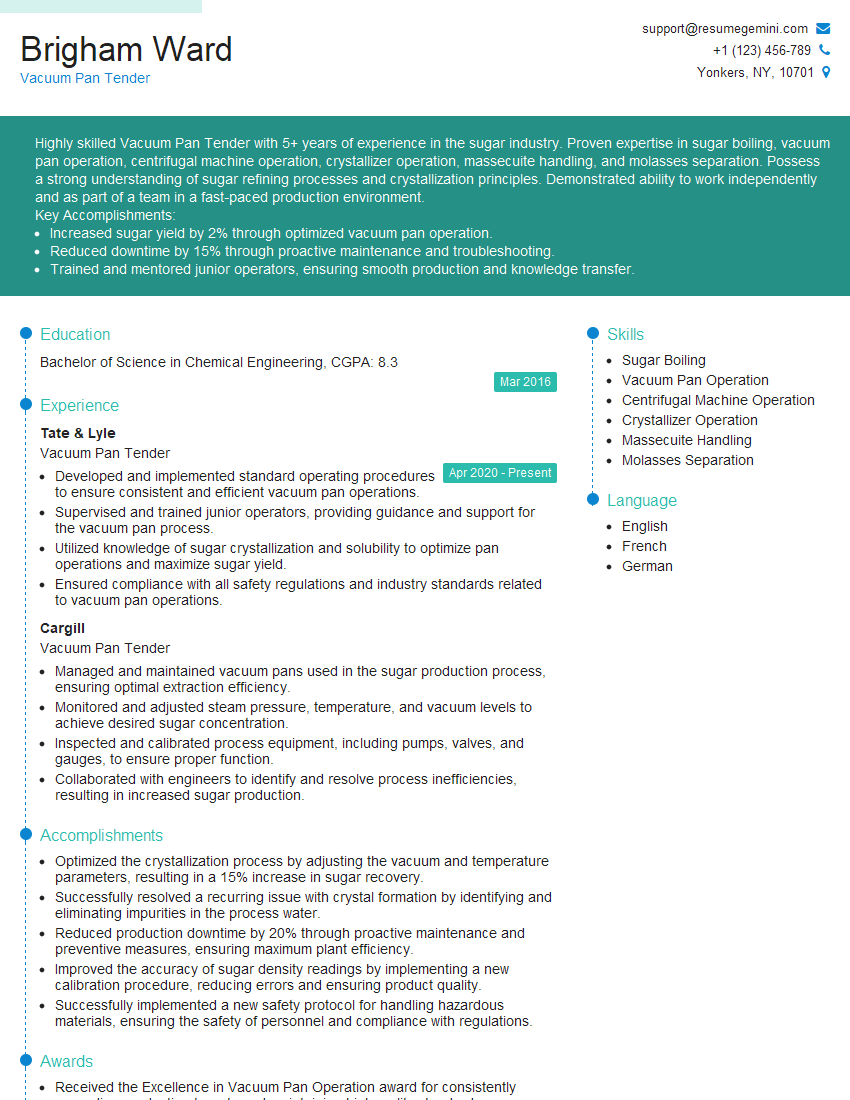

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Vacuum Pan Tender

1. Describe the process of evaporating sugar solution in a vacuum pan?

The process of evaporating sugar solution in a vacuum pan involves the following steps:

- The sugar solution is fed into the vacuum pan, which is a large, enclosed vessel.

- A vacuum is created inside the pan, which lowers the boiling point of the solution.

- Heat is applied to the pan, causing the sugar solution to boil and evaporate.

- The evaporated water vapor is removed from the pan by a condenser.

- The remaining sugar solution becomes more concentrated as the water evaporates.

- The process is continued until the desired concentration of sugar is reached.

2. What are the critical parameters that need to be controlled during vacuum pan evaporation?

Temperature

- The temperature of the sugar solution must be carefully controlled to prevent crystallization.

- The ideal temperature will vary depending on the type of sugar being processed.

Pressure

- The vacuum pressure inside the pan must be carefully controlled to maintain the desired boiling point.

- Too high vacuum can cause the sugar solution to boil too vigorously and foam.

- Too low vacuum can cause the sugar solution to boil too slowly and result in a poor-quality product.

Concentration

- The concentration of the sugar solution must be carefully controlled to prevent crystallization or the formation of unwanted by-products.

- The ideal concentration will vary depending on the desired end product.

3. What are the different types of vacuum pans used in the sugar industry?

- Calandria Vacuum Pan

- Coil Vacuum Pan

- External Calandria Vacuum Pan

- Forced Circulation Vacuum Pan

4. What are the main components of a vacuum pan?

- Body: The main vessel where evaporation takes place.

- Calandria: A bundle of tubes where heating/cooling medium circulates.

- Vapor Outlet: An outlet at the top of the pan where vapors escape.

- Feed Inlet: An inlet at the bottom of the pan where sugar solution enters.

- Discharge Valve: A valve at the bottom of the pan where the concentrated solution is discharged.

- Vacuum Breaker: A device that can break the vacuum inside the pan in case of an emergency.

- Sight Glass: A transparent window that allows the operator to see the inside of the pan.

5. What are the safety precautions that need to be followed when operating a vacuum pan?

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and a hard hat.

- Never enter a vacuum pan while it is in operation.

- Be aware of the potential for explosions and take appropriate precautions.

- Follow all operating procedures carefully.

- Report any unsafe conditions or equipment malfunctions immediately.

6. What are the common problems that can occur during vacuum pan evaporation and how can they be solved?

Foaming

- Causes: High vacuum, high temperature, or presence of impurities.

- Solutions: Reduce vacuum, lower temperature, or add an anti-foaming agent.

Crystallization

- Causes: Low temperature, high concentration, or presence of impurities.

- Solutions: Increase temperature, lower concentration, or add a crystallization inhibitor.

Scaling

- Causes: Deposition of calcium or magnesium salts on the heating surfaces.

- Solutions: Regular cleaning and use of scale inhibitors.

7. What are the maintenance procedures for a vacuum pan?

- Regular cleaning to remove scale and other deposits.

- Inspection of all components for wear and tear.

- Tightening of bolts and nuts.

- Lubrication of moving parts.

- Calibration of instruments.

8. What is the role of a vacuum pan tender in a sugar factory?

- Operate and maintain vacuum pans for the evaporation of sugar solution.

- Control and monitor the critical parameters of the evaporation process (temperature, pressure, concentration).

- Identify and troubleshoot problems with the vacuum pans.

- Ensure the safety of the equipment and personnel.

9. What skills and qualifications are required to be a vacuum pan tender?

- Technical knowledge of vacuum pan operation and maintenance.

- Experience in the sugar industry.

- Ability to work independently and as part of a team.

- Strong problem-solving skills.

- Physical ability to work in a hot and humid environment.

10. What is your experience with vacuum pan operation and maintenance?

I have worked as a vacuum pan tender in a sugar factory for the past 5 years. During that time, I have been responsible for operating and maintaining multiple vacuum pans. I have a thorough understanding of the evaporation process and can troubleshoot and solve most problems that arise.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Vacuum Pan Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Vacuum Pan Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Vacuum Pan Tenders play a crucial role in the sugar refining process by operating vacuum pans, which crystallize sugar solutions to separate the sugar crystals from the molasses. Their key responsibilities encompass:

1. Operating vacuum pans

Tenders control the temperature, pressure, and other variables within the vacuum pans to facilitate the crystallization process.

- Monitor and adjust process parameters (e.g., temperature, pressure, vacuum level)

- Control the flow of sugar solution and molasses into and out of the pans

2. Monitoring crystallization process

They closely monitor the crystallization process to ensure the formation of sugar crystals of the desired size and quality.

- Observe the crystal growth and adjust process parameters accordingly

- Take samples and perform quality checks (e.g., crystal size, purity)

3. Maintaining vacuum pans and equipment

Tenders maintain and troubleshoot the vacuum pans and associated equipment to ensure smooth operation.

- Clean and inspect pans and equipment regularly

- Identify and repair any malfunctions

4. Ensuring safety

They adhere to safety protocols and maintain a clean and safe work environment.

- Follow safety regulations and wear protective gear

- Report any potential hazards or accidents

Interview Tips

To ace the interview for the Vacuum Pan Tender position, candidates should consider the following preparation tips:

1. Research the role and company

Familiarize yourself with the specific responsibilities of a Vacuum Pan Tender and the company’s operations. Highlight how your skills and experience align with the requirements.

2. Practice your responses

Prepare answers to common interview questions, such as those related to your technical skills, experience operating vacuum pans, and knowledge of sugar refining processes. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

3. Quantify your accomplishments

When describing your experiences, provide specific examples and quantify your accomplishments using data whenever possible. This will demonstrate your impact and the value you can bring to the company.

4. Emphasize safety and attention to detail

Highlight your commitment to safety and your ability to pay meticulous attention to detail. These qualities are essential for the role of a Vacuum Pan Tender.

5. Be prepared to discuss troubleshooting experiences

Interviewers often ask about troubleshooting experiences to assess your problem-solving abilities. Prepare a few examples where you successfully identified and resolved issues related to vacuum pan operation or sugar refining processes.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Vacuum Pan Tender, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Vacuum Pan Tender positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.