Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Crusher and Blender Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Crusher and Blender Operator so you can tailor your answers to impress potential employers.

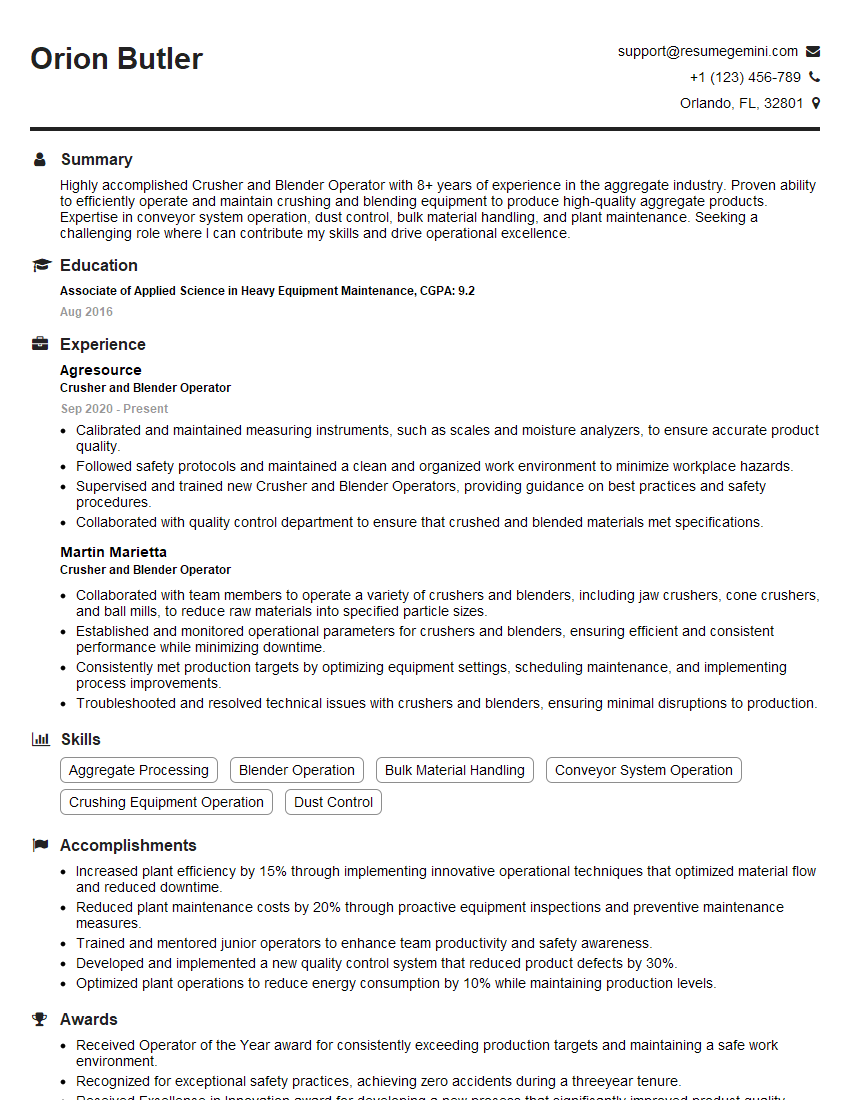

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Crusher and Blender Operator

1. Explain the basic principles of crushing and blending operations?

- Crushing involves breaking down larger materials into smaller pieces using mechanical force.

- Blending combines different materials to achieve a uniform mixture with specific properties.

2. Describe the different types of crushers and blenders you have experience with?

Jaw Crusher

- Uses a fixed and movable jaw to crush materials.

- Suitable for primary and coarse crushing.

Cone Crusher

- Employs a cone-shaped head that rotates against a concave surface.

- Provides fine and medium crushing.

Impact Crusher

- Utilizes high-speed impacts to break materials.

- Suitable for secondary and tertiary crushing.

Ribbon Blender

- Horizontal cylindrical blender with a helical ribbon agitator.

- Provides gentle blending and is suitable for delicate materials.

Paddle Blender

- Cylindrical blender with rotating paddles.

- Offers high shear mixing and is suitable for viscous materials.

3. What are the key factors to consider when selecting a crusher for a specific application?

- Material type and hardness

- Desired particle size

- Throughput capacity

- Power requirements

- Maintenance and operating costs

4. How do you determine the correct blending time for a given material combination?

- Conduct trial runs with varying blending times.

- Monitor homogeneity using appropriate testing methods.

- Establish blending time based on desired uniformity and process constraints.

5. What are the common maintenance procedures for crushers and blenders?

- Regular lubrication and inspection

- Replacement of wear parts

- Drive belt adjustments

- Electrical system maintenance

- Calibration and optimization

6. How do you troubleshoot common problems encountered in crushing and blending operations?

- Identify the symptom and potential causes.

- Inspect equipment, check settings, and verify material properties.

- Implement corrective actions based on the diagnosis.

- Monitor performance and make necessary adjustments.

7. What safety precautions should be taken when operating crushers and blenders?

- Wear appropriate PPE (protective clothing, gloves, safety glasses).

- Keep work areas clean and organized.

- Follow lock-out/tag-out procedures during maintenance.

- Avoid loose clothing or jewelry that could get caught in equipment.

8. How do you ensure the quality of the final crushed and blended product?

- Establish quality standards and specifications.

- Monitor particle size distribution and uniformity.

- Conduct regular product testing to verify compliance.

- Implement quality control measures throughout the process.

9. What are the latest advancements in crushing and blending technology?

- Automated control systems for optimized performance.

- Advanced sensor technology for real-time monitoring.

- High-efficiency crushers with reduced power consumption.

- Innovative blending techniques for improved homogeneity.

10. How do you stay updated on the latest industry trends and best practices in crushing and blending?

- Attend industry events and conferences.

- Read technical journals and publications.

- Network with professionals in the field.

- Participate in professional development programs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Crusher and Blender Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Crusher and Blender Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Crusher and Blender Operator is responsible for the efficient operation and maintenance of crushing and blending equipment in a production plant. They work closely with other operators, supervisors, and technicians to ensure that production processes run smoothly and safely.

1. Operate and Maintain Crushing Equipment

Crusher and Blender Operators operate various types of crushing equipment, such as jaw crushers, gyratory crushers, and cone crushers. They are responsible for setting up, adjusting, and maintaining these machines to ensure they meet production requirements.

- Monitor crushing operations and make adjustments to optimize output

- Inspect and maintain crushing equipment to identify and resolve potential issues

2. Operate and Maintain Blending Equipment

In addition to crushing operations, Crusher and Blender Operators are also responsible for operating and maintaining blending equipment. They use blending systems to combine different materials or ingredients in a consistent manner.

- Operate blending systems to ensure desired ratios and consistency of materials

- Perform routine maintenance and calibration of blending equipment

3. Monitor Production Processes

Crusher and Blender Operators are responsible for monitoring production processes and making adjustments as needed. They use various instruments and sensors to monitor parameters such as temperature, pressure, and flow rates.

- Monitor production processes to identify and resolve deviations from set parameters

- Collect and record data on production rates and equipment performance

4. Maintain a Safe and Clean Work Environment

Crusher and Blender Operators are responsible for maintaining a safe and clean work environment. They follow established safety protocols and procedures, including wearing appropriate safety gear and keeping equipment in good working order.

- Comply with all safety regulations and procedures

- Keep work area clean and organized to promote safety and efficiency

Interview Tips

Preparing thoroughly for your interview can significantly increase your chances of success. Here are some tips to help you ace the interview for a Crusher and Blender Operator position:

1. Research the Company and Role

Take the time to learn about the company you are applying to and the specific role of a Crusher and Blender Operator within that company. This will help you understand the company’s culture, values, and expectations for the position.

- Visit the company’s website and social media pages

- Read industry news and articles to stay up-to-date on industry trends

2. Practice Answering Common Interview Questions

There are several common interview questions that you are likely to encounter in an interview for a Crusher and Blender Operator position. Practice answering these questions clearly and concisely, highlighting your relevant skills and experience.

- Tell me about your experience operating crushing and blending equipment.

- Describe a time when you had to troubleshoot a problem with a crushing or blending machine.

- How do you ensure safety in your workplace?

3. Highlight Your Technical Skills

Crusher and Blender Operators need to have a strong understanding of crushing and blending equipment. Be sure to highlight your technical skills in your resume and during the interview. This could include experience with specific types of crushing and blending machines.

- List any certifications or training you have received in the operation and maintenance of crushing and blending equipment

- Demonstrate your knowledge of process control systems and instrumentation

4. Emphasize Your Problem-Solving Abilities

Crusher and Blender Operators often need to solve problems that arise during production. Highlight your problem-solving abilities in your resume and during the interview. This could include examples of times when you have identified and resolved issues with crushing or blending equipment.

- Describe a time when you successfully diagnosed and fixed a problem with a crushing or blending machine

- Explain how you approach problem-solving in a systematic and organized manner

Next Step:

Now that you’re armed with the knowledge of Crusher and Blender Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Crusher and Blender Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini