Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Feed Crusher Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

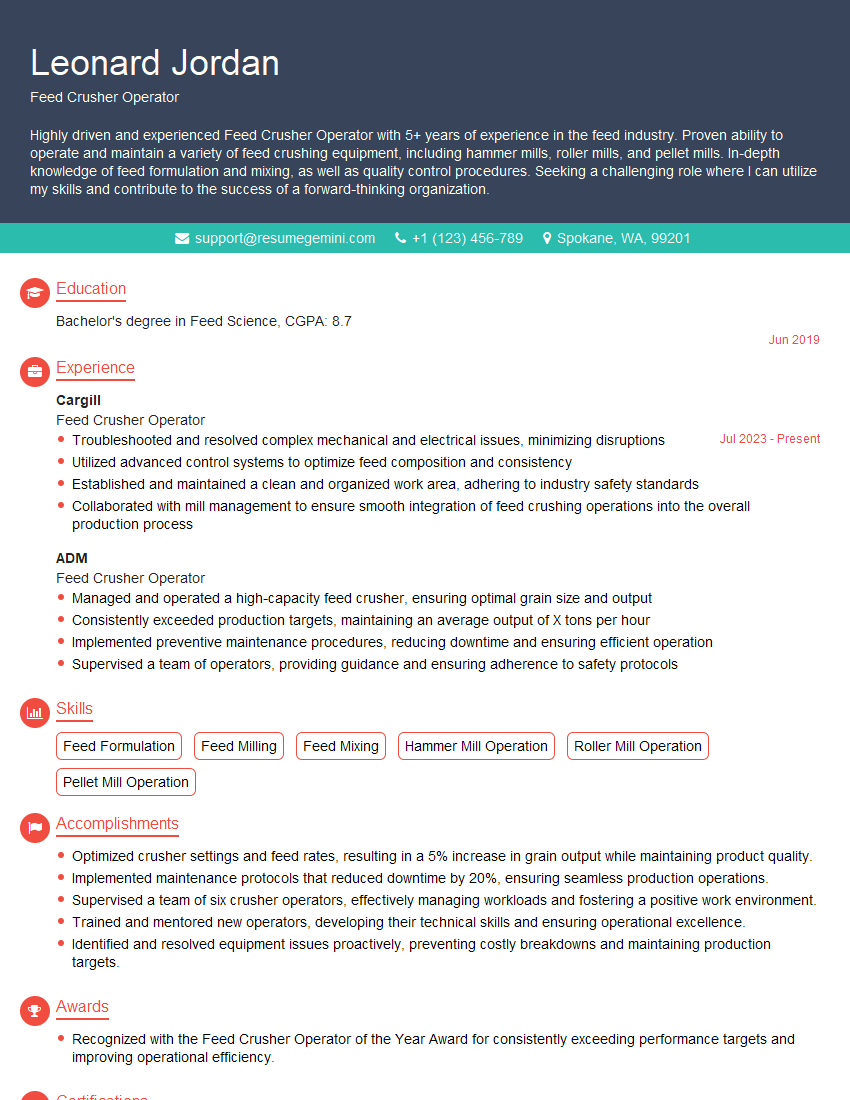

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Feed Crusher Operator

1. How do you determine the correct settings for the feed crusher based on the material being processed?

To determine the correct settings for the feed crusher, I consider the following factors:

- Material hardness and size: Harder and larger materials require a smaller screen size and higher roll pressure.

- Desired particle size: The feed crusher settings should be adjusted to achieve the desired particle size distribution.

- Feed rate: The feed crusher should be operated at a rate that ensures proper crushing without overloading.

- Screen size: The screen size should be selected to retain the desired particle size and remove oversized materials.

2. What are the key maintenance procedures for a feed crusher and how often should they be performed?

Daily Maintenance

- Inspect the feed crusher for any wear or damage.

- Lubricate all moving parts.

- Check the tension of the drive belts.

Weekly Maintenance

- Inspect the screen for wear or damage.

- Clean the feed crusher thoroughly.

- Check the oil level in the gearbox.

Monthly Maintenance

- Replace the screen if necessary.

- Check the condition of the bearings.

- Perform a vibration analysis to identify any potential issues.

3. How do you troubleshoot a feed crusher that is not performing optimally?

When troubleshooting a feed crusher that is not performing optimally, I follow these steps:

- Inspect the feed crusher for any obvious issues: Check for loose belts, worn screens, or damaged components.

- Check the power supply and electrical connections: Ensure that the feed crusher is receiving adequate power and that all electrical connections are secure.

- Adjust the feed crusher settings: Verify that the settings are appropriate for the material being processed.

- Inspect the material being processed: Check for any contaminants or oversize materials that may be causing the issue.

- Consult the manufacturer’s manual or contact technical support: If the issue cannot be resolved through the above steps, refer to the manufacturer’s documentation or seek professional assistance.

4. What are the safety precautions that must be taken when operating a feed crusher?

When operating a feed crusher, it is imperative to adhere to the following safety precautions:

- Wear appropriate personal protective equipment: This includes safety glasses, earplugs, gloves, and a dust mask.

- Keep hands and loose clothing away from moving parts: Ensure that long hair or loose clothing cannot become entangled in the feed crusher.

- Never reach into the feed crusher while it is operating: If a blockage occurs, stop the feed crusher and disconnect the power supply before attempting to clear it.

- Be aware of the location of emergency stop buttons: In the event of an emergency, immediately press the emergency stop button to shut down the feed crusher.

- Follow all manufacturer’s instructions and safety guidelines: Refer to the operator’s manual for specific safety procedures and precautions.

5. How do you calculate the production capacity of a feed crusher?

To calculate the production capacity of a feed crusher, I consider the following factors:

- Feed rate: The amount of material that is fed into the crusher per unit time.

- Type of material being processed: The hardness, size, and moisture content of the material can affect the production capacity.

- Feed crusher settings: The settings of the feed crusher, such as the screen size and roll pressure, can impact the production rate.

- Efficiency of the feed crusher: The overall efficiency of the feed crusher, accounting for any downtime or maintenance requirements.

6. How do you handle a situation where the feed crusher is overloaded?

If the feed crusher is overloaded, I take the following steps:

- Stop the feed crusher immediately: Prevent further damage to the machine by shutting it down.

- Identify the cause of the overload: Check if the feed rate is too high or if the material being processed is too large or hard.

- Adjust the feed crusher settings: If necessary, adjust the feed rate or screen size to accommodate the material being processed.

- Clear the overload: Remove any excess material from the feed crusher and ensure that it is operating smoothly before restarting.

- Monitor the feed crusher closely after restarting: Ensure that the overload does not occur again and make further adjustments if necessary.

7. How do you ensure that the feed crusher is operating at optimal efficiency?

- Regular maintenance: Perform scheduled maintenance tasks, such as lubrication, screen inspection, and bearing checks, to keep the feed crusher in good working condition.

- Proper feed preparation: Ensure that the material being processed is free of contaminants and is sized appropriately for the feed crusher.

- Optimal settings: Adjust the feed crusher settings, such as the screen size and roll pressure, to achieve the desired particle size and production rate.

- Monitoring and troubleshooting: Regularly monitor the feed crusher’s performance and troubleshoot any issues promptly to prevent downtime and maintain efficiency.

8. How do you handle a situation where the feed crusher breaks down?

- Safety first: Disconnect the power supply and ensure the safety of personnel before proceeding with repairs.

- Identify the problem: Inspect the feed crusher and identify the cause of the breakdown, whether it’s a mechanical failure, electrical issue, or material blockage.

- Contact maintenance: If the issue is beyond your expertise or requires specialized tools, contact the maintenance department for assistance.

- Temporary measures: If possible, implement temporary measures to minimize downtime, such as adjusting the feed rate or diverting the material to a backup crusher.

- Repair or replace: Depending on the severity of the breakdown, repair the affected components or replace them as necessary to restore the feed crusher to operation.

9. How do you ensure the safety of yourself and others when working with a feed crusher?

- Personal protective equipment: Wear appropriate safety gear, including earplugs, safety glasses, gloves, and a dust mask, to protect against noise, flying particles, and dust.

- Lockout/tagout procedures: Follow proper lockout/tagout procedures to prevent accidental startup during maintenance or repairs.

- Clear work area: Keep the work area around the feed crusher clean and free of obstacles to prevent tripping or slipping.

- Be aware of surroundings: Pay attention to your surroundings and be aware of the location of emergency stop buttons in case of an emergency.

- Training and supervision: Ensure that all operators are properly trained and supervised to operate the feed crusher safely.

10. How do you stay up-to-date with the latest advancements in feed crushing technology?

- Industry publications and conferences: Attend industry conferences and read trade publications to stay informed about new technologies and best practices.

- Manufacturer updates: Subscribe to manufacturer newsletters and product updates to receive information about new equipment and advancements.

- Online forums and discussions: Engage in online discussions and forums related to feed crushing technology to exchange knowledge and insights with other professionals.

- Continuing education: Consider pursuing additional education or certifications to enhance your knowledge and skills in feed crushing operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Feed Crusher Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Feed Crusher Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Feed Crusher Operator, you will play a pivotal role in ensuring the smooth and efficient operation of the feed crushing process. Your duties will primarily entail:

1. Feed Crushing and Monitoring

- Operate feed crushing machinery, such as hammer mills and roller mills, to crush and grind raw feed ingredients

- Monitor crushing processes closely to ensure optimal particle size and quality in accordance with specifications

- Calibrate and adjust crushing machinery to achieve desired results

2. Raw Material Management

- Receive, inspect, and prepare raw feed materials for crushing

- Store and handle raw materials properly to maintain their quality and prevent spoilage

3. Quality Control

- Conduct regular quality checks on crushed feed to ensure it meets specifications

- Identify and resolve any quality issues promptly

4. Equipment Maintenance

- Perform routine maintenance on crushing machinery, including lubrication, cleaning, and adjustments

- Identify and report any equipment issues or malfunctions for timely repairs

5. Safety and Compliance

- Follow all safety protocols and operating procedures to ensure a safe work environment

- Comply with all applicable regulations and standards related to feed crushing operations

Interview Tips

Preparing for an interview for a Feed Crusher Operator position requires a thorough understanding of the role and industry. Here are some tips and hacks to help you ace your interview:

1. Research the Company and Industry

- Explore the company’s website, LinkedIn page, and news articles to gain insights into their business, values, and products

- Research the feed industry to understand its current trends, regulations, and best practices

2. Highlight Relevant Experience and Skills

- Emphasize your experience in operating feed crushing machinery and your knowledge of different types of crushing methods

- Showcase your understanding of raw material handling, quality control, and safety procedures

3. Practice Common Interview Questions

- Prepare for questions about your experience, skills, and motivations for applying for the role

- Rehearse answers to behavioral questions, such as “Tell me about a time you faced a challenge in crushing operations and how you overcame it”

4. Ask Thoughtful Questions

- Prepare specific questions about the company, the position, and the industry to demonstrate your interest and engagement

- Inquire about the company’s commitment to safety, sustainability, and employee development

5. Dress Professionally and Arrive Punctually

- Make a good first impression by dressing appropriately for the interview

- Arrive on time to show your respect for the interviewer and the company

Next Step:

Now that you’re armed with the knowledge of Feed Crusher Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Feed Crusher Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini