Feeling lost in a sea of interview questions? Landed that dream interview for Feed Mill Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Feed Mill Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

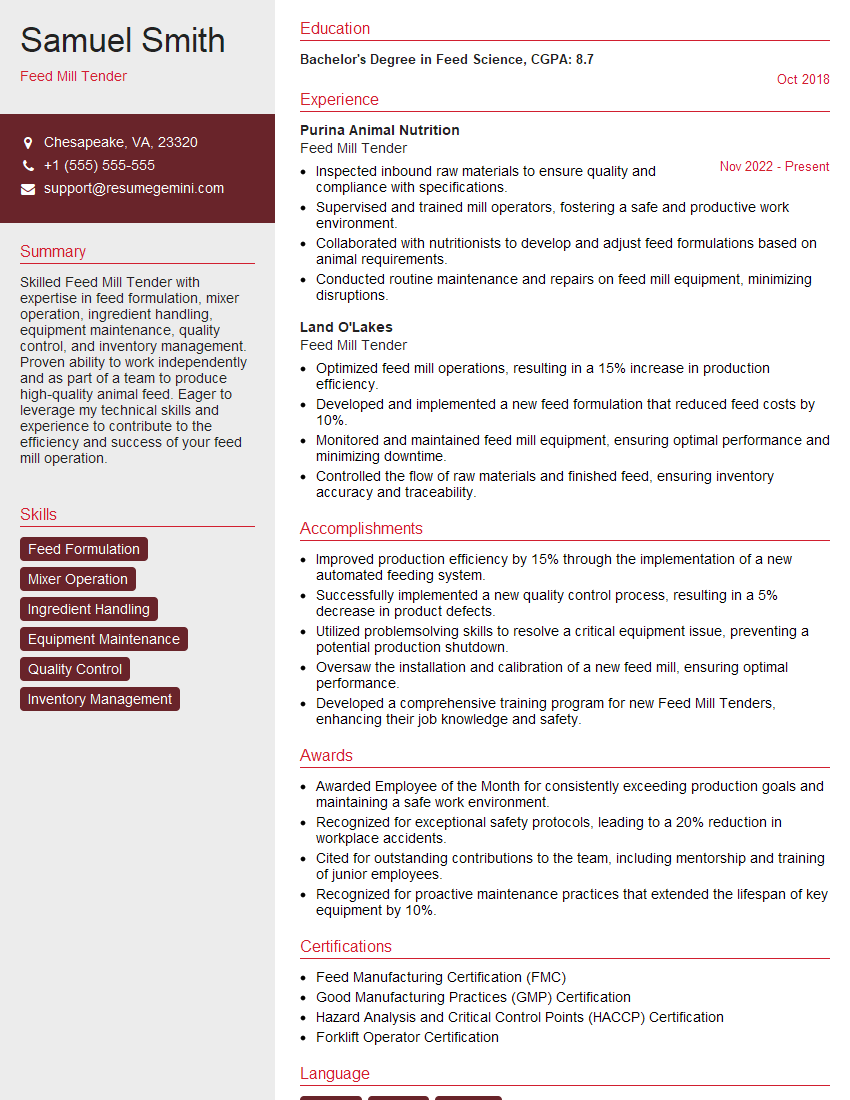

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Feed Mill Tender

1. Describe the steps involved in mixing animal feed in a feed mill?

In a feed mill, mixing animal feed involves several key steps:

- Recipe formulation: Determine the desired nutrient composition and ratios of ingredients based on the specific needs of the animals being fed.

- Ingredient handling: Receive, inspect, and store various feed ingredients, including grains, proteins, vitamins, and minerals.

- Grinding: Reduce the size of grains and other ingredients to improve mixing efficiency and better digestibility for animals.

- Batching: Measure and weigh the required quantities of each ingredient according to the recipe formulation.

- Mixing: Combine the ingredients in a mixer, ensuring thorough and uniform blending to achieve the desired nutritional profile.

- Pelleting or extruding: Optionally, process the mixed feed into pellets or extruded forms for enhanced handling, storage, and digestibility.

- Packaging: Fill and seal bags, bulk containers, or other packaging materials with the finished feed product.

2. How do you ensure the quality and safety of mixed feed?

Monitoring Ingredients:

- Inspect incoming ingredients for quality and compliance with specifications.

- Test ingredients for contaminants, mycotoxins, and other hazards.

- Store ingredients appropriately to maintain their nutritional value and prevent spoilage.

Production Process Control:

- Follow established mixing procedures and recipes precisely.

- Calibrate and maintain mixing equipment regularly.

- Monitor mixing time and temperature to ensure proper blending and feed quality.

- Conduct quality checks throughout the mixing process.

Post-Mixing Verification:

- Sample and analyze finished feed to verify nutritional content and meet quality specifications.

- Document all quality control measures and maintain records for traceability.

3. What are the different types of equipment used in a feed mill and their functions?

- Grinders: Reduce particle size of grains and other ingredients to enhance mixing and digestibility.

- Mixers: Combine ingredients and ensure thorough blending to achieve uniform nutritional composition.

- Pellet mills/Extruders: Shape and process feed into pellets or extruded forms for better handling, storage, and animal consumption.

- Conveyors: Transport ingredients and finished feed throughout the mill.

- Bins/Silos: Store raw materials and finished feed products.

- Weighing and batching systems: Measure and control the quantities of ingredients added to the mix.

- Monitoring and control systems: Track and adjust mixing parameters to maintain feed quality and safety.

4. How do you maintain and troubleshoot common issues with feed mill equipment?

Maintaining and troubleshooting feed mill equipment involves several steps:

- Regular inspections: Conduct routine inspections of equipment to identify potential issues early on.

- Preventative maintenance: Follow manufacturer’s recommendations for scheduled maintenance, including cleaning, lubrication, and calibrations.

- Troubleshooting: When issues arise, analyze symptoms, identify the root cause, and implement appropriate corrective actions.

- Spare parts inventory: Maintain a stock of common spare parts to minimize downtime during repairs.

- Training: Ensure operators are trained on proper equipment operation and maintenance procedures.

5. Explain the importance of following safety protocols in a feed mill?

- Preventing accidents: Adhering to safety protocols reduces the risk of injuries, spills, explosions, and other accidents.

- Protecting equipment: Proper handling and maintenance practices extend equipment lifespan and prevent costly repairs.

- Maintaining a clean and organized workplace: A well-maintained facility promotes efficiency and reduces hazards.

- Complying with regulations: Following safety protocols ensures compliance with industry standards and legal requirements.

- Protecting the environment: Proper waste management and spill prevention measures minimize environmental impact.

6. Describe your experience with feed mill automation systems?

In my previous role at [Mill Name], I was responsible for operating and maintaining the mill’s automated systems.

- Monitored and adjusted ingredient flow rates using programmable logic controllers (PLCs).

- Programmed and troubleshooted PLC logic to optimize mixing operations.

- Utilized data acquisition systems to collect and analyze production data for performance improvement.

- Collaborated with the IT team to ensure seamless integration and support.

7. How do you stay updated with the latest advancements in feed mill technology?

- Attend industry conferences and seminars: Engage with experts and learn about new technologies and best practices.

- Read technical journals and publications: Stay informed about research and developments in the field.

- Visit vendor websites and exhibitions: Explore innovative solutions and equipment from manufacturers.

- Network with peers: Connect with other feed mill operators and exchange knowledge on advancements.

- Participate in training programs: Enhance skills and gain hands-on experience with new technologies.

8. How do you handle stress and work effectively in a fast-paced feed mill environment?

- Prioritize tasks: Manage workload by identifying and focusing on critical activities.

- Delegate responsibilities: When possible, assign tasks to others to streamline operations.

- Stay organized: Maintain a clean and well-organized workspace to reduce distractions and improve efficiency.

- Take breaks: Step away from work periodically to clear the mind and recharge.

- Communicate effectively: Share information with colleagues and supervisors to avoid misunderstandings and delays.

9. Describe your experience in managing a team of feed mill operators?

As the Feed Mill Supervisor at [Mill Name], I led a team of 10 operators responsible for daily mixing operations.

- Provided training and guidance to ensure proficiency and safety.

- Delegated tasks and monitored progress to meet production targets.

- Motivated the team and recognized their contributions.

- Conducted performance evaluations and provided feedback for improvement.

- Maintained a positive and collaborative work environment.

10. How do you prioritize customer satisfaction in your role?

- Understanding customer needs: Actively listen to and understand the specific requirements of feed customers.

- Meeting specifications: Ensure that the feed produced meets or exceeds the nutritional specifications agreed upon with customers.

- Timely delivery: Prioritize order fulfillment to minimize customer wait times.

- Open communication: Maintain regular communication with customers to address any concerns or feedback.

- Continuous improvement: Seek opportunities to enhance products and services based on customer input.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Feed Mill Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Feed Mill Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Feed Mill Tender

A Feed Mill Tender plays a vital role in maintaining and operating feed mills, ensuring the efficient production of animal feed.

1. Mill Maintenance and Operation

Operate, monitor, and adjust feed mill equipment, including grinders, mixers, conveyors, and packaging machines.

- Maintain equipment by performing regular inspections, cleaning, lubrication, and repairs.

- Troubleshoot and resolve operational issues promptly to minimize downtime.

2. Ingredient Handling

Receive, weigh, and store raw materials and finished feed products in accordance with safety and quality standards.

- Maintain inventory records and monitor ingredient usage to ensure smooth production.

- Coordinate with suppliers and handle deliveries to maintain adequate stock levels.

3. Quality Control

Monitor and test feed samples to ensure compliance with nutritional specifications.

- Conduct sensory inspections of finished feed to assess quality and appearance.

- Follow established quality control procedures and adhere to Good Manufacturing Practices (GMPs).

4. Health and Safety

Maintain a clean and safe work environment by following proper safety protocols.

- Wear personal protective equipment (PPE) and use appropriate safety procedures when handling equipment and materials.

- Follow company safety regulations and undergo necessary training to maintain a safe workplace.

Interview Tips for Feed Mill Tenders

To ace an interview for a Feed Mill Tender position, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s operations, industry trends, and the specific responsibilities of the Feed Mill Tender role.

- Visit the company website, read industry publications, and connect with current or former employees on LinkedIn.

- Prepare questions that demonstrate your understanding of the role and how you can contribute to the company’s success.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in feed mill operations, equipment maintenance, and quality control.

- Quantify your accomplishments with specific examples of how you improved efficiency, reduced downtime, or ensured product quality.

- Highlight your knowledge of industry best practices and any relevant certifications or training you have completed.

3. Demonstrate Teamwork and Communication

Feed Mill Tenders often work in a team environment and interact with various departments.

- Provide examples of how you have effectively collaborated with colleagues, maintained open communication, and resolved conflicts.

- Explain how you share information and coordinate with other departments, such as production, quality control, and logistics.

4. Emphasize Safety and Attention to Detail

Safety and attention to detail are paramount in a feed mill environment.

- Share examples of your commitment to safety, such as adhering to PPE protocols, conducting thorough inspections, and reporting potential hazards.

- Highlight your ability to follow procedures precisely, paying attention to details, and maintaining an organized work area.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Feed Mill Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!