Are you gearing up for a career in Finish Machine Tender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Finish Machine Tender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

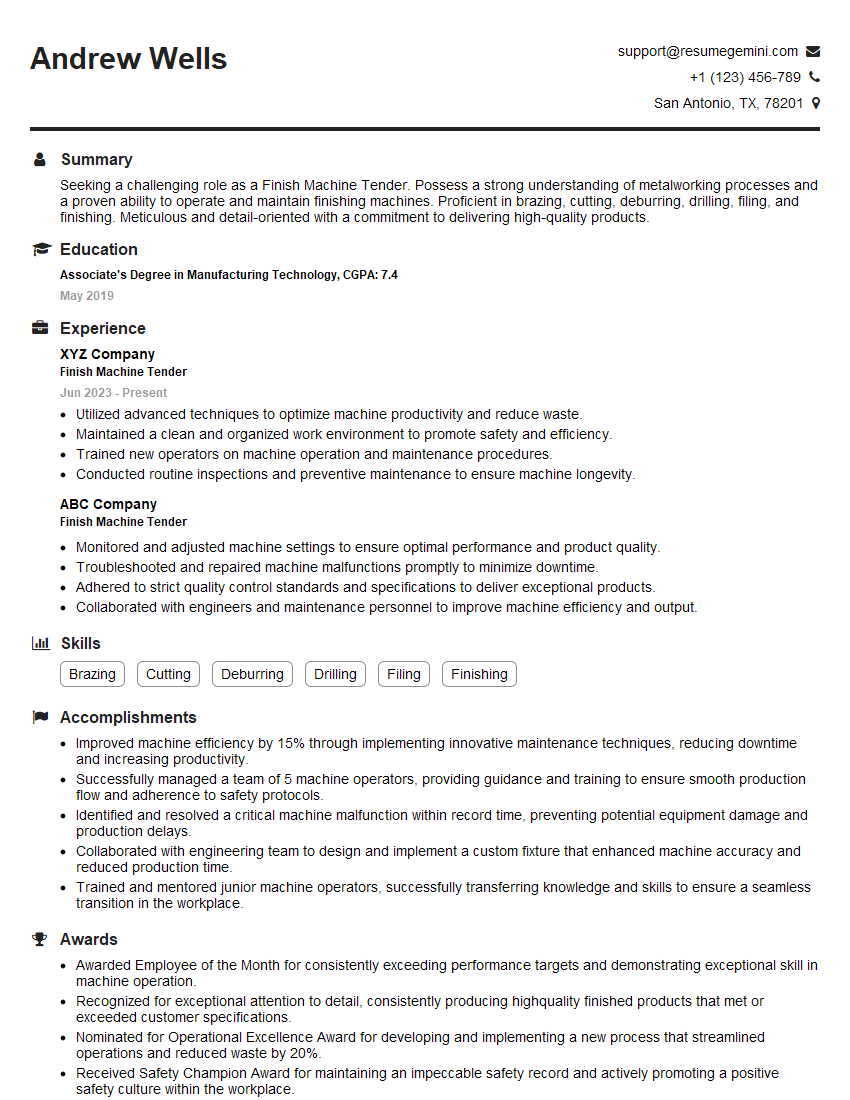

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Finish Machine Tender

1. What are the key responsibilities of a Finish Machine Tender?

As a Finish Machine Tender, my primary responsibilities include:

- Operating and monitoring automated finishing machinery, such as grinders, polishers, and buffers.

- Ensuring finished products meet specifications for surface finish, dimensions, and tolerances.

- Inspecting raw materials and finished products for defects and non-conformities.

- Performing regular maintenance and repairs on finishing equipment to maintain optimal performance.

- Adhering to safety protocols and maintaining a clean and organized work area.

2. Describe the types of finishing processes you are familiar with and the equipment used in each process.

Grinding

- Use grinders to remove excess material or smooth surfaces.

- Adjust grinding wheels based on material type and desired finish.

Polishing

- Operate polishing machines to achieve a smooth and shiny surface.

- Select appropriate polishing compounds and abrasives.

Buffing

- Use buffers to remove fine scratches and impart a high gloss finish.

- Choose appropriate buffing wheels and compounds for different materials.

3. How do you ensure that finished products meet the required surface finish specifications?

- Review product drawings and specifications to understand surface finish requirements.

- Use calibrated measuring instruments, such as profilometers and gloss meters, to measure surface roughness and finish.

- Adjust finishing parameters, such as machine speed, feed rate, and abrasive grit, to achieve desired surface quality.

4. What are the common defects you encounter in finished products and how do you address them?

- Scratches and gouges: Identify the source of the scratches and use polishing or buffing to remove them.

- Dimensional errors: Measure the product and adjust machine settings to ensure correct dimensions.

- Corrosion: Determine the cause of corrosion and implement preventive measures, such as using corrosion-resistant coatings.

5. How do you maintain and calibrate finishing equipment to ensure accuracy and efficiency?

- Follow manufacturer’s instructions for regular maintenance and lubrication.

- Use calibrated tools and instruments to ensure accuracy of measurements.

- Inspect equipment for any signs of wear or damage and promptly address issues.

6. What safety precautions do you take when operating finishing machinery?

- Wear appropriate personal protective equipment (PPE), such as gloves, eye protection, and hearing protection.

- Ensure work area is well-ventilated to avoid exposure to harmful fumes or dust.

- Follow lockout/tagout procedures when performing maintenance or repairs on equipment.

7. How do you stay updated with the latest finishing techniques and technologies?

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Consult with equipment manufacturers and industry experts.

8. What is your experience with troubleshooting and resolving equipment malfunctions?

- Identify potential causes of malfunctions by analyzing symptoms and error codes.

- Refer to maintenance manuals and consult with experienced technicians for guidance.

- Perform necessary repairs or adjustments to restore equipment to optimal operation.

9. How do you prioritize tasks and manage your time effectively when working in a production environment?

- Create a work schedule based on production targets and deadlines.

- Identify critical tasks and allocate resources accordingly.

- Delegate responsibilities and collaborate with team members to ensure efficient workflow.

10. Why are you interested in this particular Finish Machine Tender position?

I am eager to contribute my skills and experience in finish machining to your company. I am confident that I can leverage my technical abilities and commitment to quality to support your production goals. Moreover, I am passionate about staying abreast of industry advancements and embracing innovative techniques to optimize finishing processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Finish Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Finish Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Finish Machine Tenders are primarily responsible for operating and maintaining finishing machines in the manufacturing industry. Their core duties include:

1. Machine Operation

Effectively operate finishing machines to perform various tasks such as polishing, buffing, grinding, and deburring.

- Set up and adjust machines according to product specifications.

- Load and unload materials into and from machines.

2. Quality Control

Inspect the quality of finished products and ensure that they meet the desired standards.

- Monitor the machines’ performance and make necessary adjustments to maintain quality output.

- Identify and resolve any defects or issues with the finished products.

3. Machine Maintenance

Perform routine maintenance tasks to keep the finishing machines in optimal condition.

- Clean and lubricate machines.

- Replace worn or damaged parts.

4. Safety Compliance

Adhere to established safety protocols and regulations.

- Wear appropriate personal protective equipment (PPE).

- Follow lockout/tagout procedures.

Interview Tips

To ace an interview for a Finish Machine Tender position, candidates should prepare thoroughly and consider the following tips:

1. Research the Company and Position

Gain an in-depth understanding of the company’s products, practices, and the specific requirements of the Finish Machine Tender role.

2. Practice Answering Common Interview Questions

Anticipate and prepare responses to frequently asked interview questions related to your skills, experience, and qualifications.

- Example Outline:

- Tell us about your experience operating finishing machines.

- – Begin with a brief overview of your relevant experience.

- – Provide specific examples of your skills, such as operating different types of machines, setting up and adjusting parameters, and troubleshooting issues.

- – Highlight your accomplishments and quantifiable results whenever possible.

3. Showcase Your Quality Control Abilities

Demonstrate your knowledge and experience in maintaining quality standards and identifying and resolving defects.

4. Emphasize Your Safety Consciousness

Convey your commitment to following safety procedures and your understanding of the importance of maintaining a safe work environment.

- Example Outline:

- Describe your experience with lockout/tagout procedures.

- – Explain the purpose and steps involved in lockout/tagout.

- – Provide an example of a situation where you successfully applied these procedures.

5. Be Confident and Enthusiastic

Project a positive and confident demeanor during the interview. Express your enthusiasm for the role and the opportunity to contribute your skills to the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Finish Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!