Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the First Crusher interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a First Crusher so you can tailor your answers to impress potential employers.

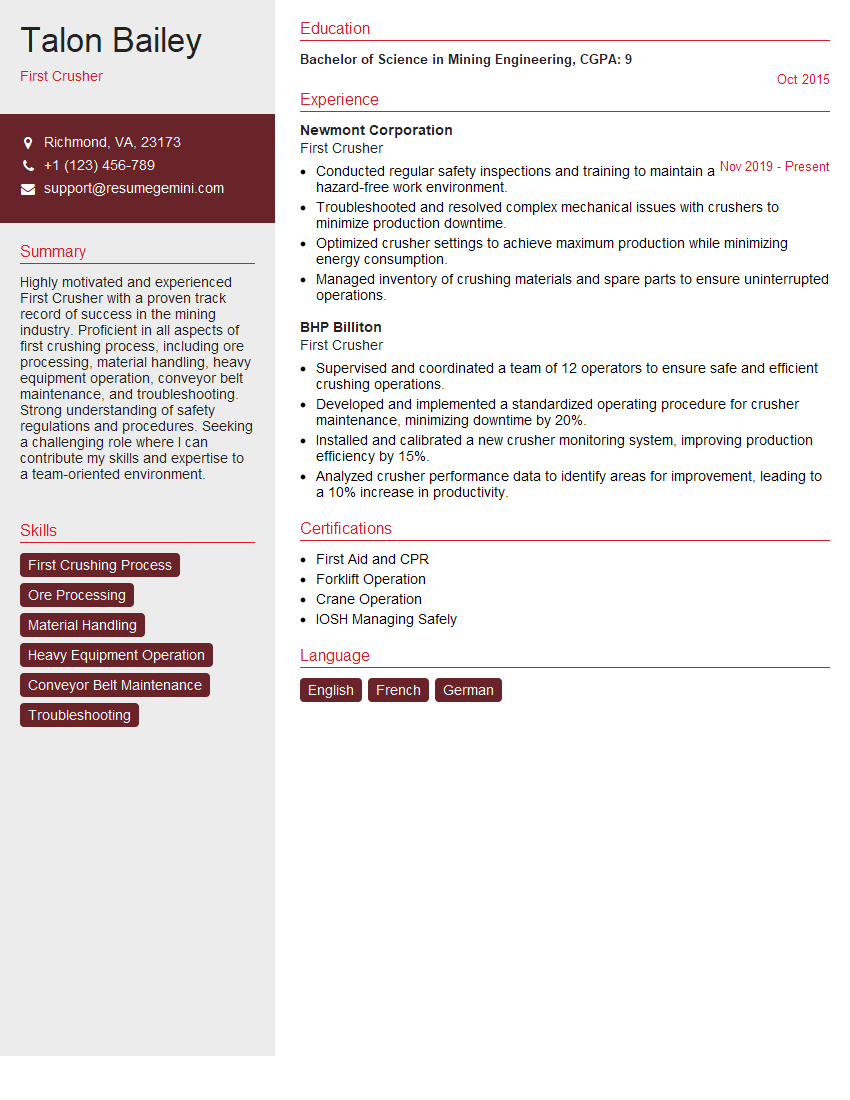

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For First Crusher

1. Describe the process of crushing and screening aggregates.

The process of crushing and screening aggregates involves several key steps to produce aggregates of desired size and shape for various construction applications:

- Quarrying: Raw materials are extracted from quarries or mines using techniques such as blasting or excavation.

- Primary Crushing: Large rocks are broken down into smaller pieces using primary crushers like jaw crushers or impact crushers.

- Secondary Crushing: The partially crushed material undergoes further reduction in size using secondary crushers like cone crushers or vertical shaft impactors.

- Screening: The crushed material is passed through screens to separate aggregates of different sizes. Screens can be vibrating, rotating, or stationary.

- Stockpiling: The screened aggregates are stored in piles or stockpiles based on their size and specifications.

2. What are the different types of crushing equipment used in the aggregate industry?

Jaw Crushers

- Fixed and movable jaws with a V-shaped opening.

- Material is compressed and broken as it passes through the jaws.

Impact Crushers

- High-speed rotating hammers impact the material.

- Produces more cubical-shaped aggregates.

Cone Crushers

- Conical-shaped chamber with a rotating mantle.

- Material is compressed and crushed as it moves through the chamber.

Vertical Shaft Impactors (VSI)

- High-speed rotors with impact bars.

- Produces fine aggregates and sand.

3. What factors influence the selection of a crushing plant?

The selection of a crushing plant depends on several factors:

- Material Characteristics: The type of rock, hardness, abrasiveness, and size distribution of the material being processed.

- Production Capacity: The desired output tonnage per hour or day.

- Product Specifications: The required size and shape of the finished aggregates.

- Site Conditions: Space availability, terrain, and environmental regulations.

- Operational Costs: Cost of equipment, maintenance, energy consumption, and labor.

4. Explain the concept of “open circuit” and “closed circuit” crushing systems.

Open Circuit Crushing

In an open circuit system, the crushed material is not screened or recycled back into the crusher.

- Produces a wide range of aggregate sizes.

- Suitable for applications where product size consistency is not critical.

Closed Circuit Crushing

In a closed circuit system, the crushed material is screened, and the oversize material is recycled back into the crusher.

- Produces a more consistent aggregate size.

- Higher efficiency and production rates.

5. What are the key maintenance considerations for crushing equipment?

Proper maintenance is crucial to ensure optimal performance and longevity of crushing equipment:

- Regular Inspections: Visual inspections, vibration monitoring, and oil analysis.

- Wear Part Replacements: Timely replacement of worn jaws, hammers, liners, and bearings.

- Lubrication: Proper lubrication of bearings, gears, and other moving parts.

- Calibration and Adjustments: Checking and adjusting crusher settings to maintain desired product size and efficiency.

- Scheduled Overhauls: Comprehensive inspections and repairs at regular intervals.

6. Discuss the environmental impact of crushing operations.

Crushing operations can have several environmental impacts:

Noise Pollution

- Noise generated by crushers, screens, and conveyors.

- Noise barriers and enclosures can be used to mitigate the impact.

Dust Emissions

- Dust generated during crushing and handling of aggregates.

- Dust collectors and water sprays can be employed to control emissions.

Water Consumption

- Water used for dust suppression and equipment cleaning.

- Water conservation measures and recycling systems can minimize consumption.

7. Describe the role of automation in modern crushing plants.

Automation plays a significant role in improving the efficiency and safety of crushing plants:

- Process Control: Automated systems monitor and adjust crusher settings, screen sizes, and conveyors.

- Equipment Monitoring: Sensors and data analytics provide real-time information on equipment performance and maintenance needs.

- Safety Enhancements: Automated systems can reduce the risk of accidents by eliminating manual interventions.

- Data Analysis: Automated systems collect and analyze operational data to optimize production and identify areas for improvement.

8. Discuss the latest trends and innovations in crushing technology.

The crushing industry is constantly evolving with new technologies and innovations:

- Hybrid Crushers: Combining different crushing mechanisms to improve efficiency and reduce wear.

- Intelligent Crusher Control: Advanced algorithms and machine learning to optimize crusher performance.

- Sustainable Crushing: Focus on reducing environmental impact through energy-efficient equipment and dust control measures.

- Remote Monitoring and Diagnostics: Cloud-based systems for remote monitoring and troubleshooting of crushing plants.

9. How do you stay updated with the latest developments in the crushing industry?

To stay informed about the latest developments in the crushing industry, I regularly engage in the following activities:

- Attend Industry Events: Participating in conferences, trade shows, and workshops to network with experts and learn about new technologies.

- Read Industry Publications: Subscribing to magazines, journals, and online resources to keep up with industry trends.

- Online Research: Exploring websites, forums, and research papers to stay informed about advancements in crushing equipment and techniques.

- Connect with Manufacturers: Establishing relationships with equipment manufacturers to learn about new products and developments.

10. Describe your experience in troubleshooting and resolving issues in crushing operations.

In my previous role at [Previous Company], I encountered several challenges and implemented effective troubleshooting strategies to resolve them:

- Excessive Wear on Crusher Jaws: Analyzed wear patterns, adjusted crusher settings, and optimized feed material to reduce wear and extend jaw life.

- Screen Clogging: Identified the source of blockage, adjusted screen mesh size, and implemented water sprays to prevent material buildup.

- Dust Control Issues: Implemented a combination of wet dust suppression and bag house filtration systems to effectively control dust emissions.

- Equipment Downtime: Conducted thorough inspections, identified faulty components, and implemented preventive maintenance measures to minimize unplanned downtime.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for First Crusher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the First Crusher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

First Crushers are responsible for operating and maintaining crushers in a metallurgical plant. They ensure that the crushers are running smoothly and efficiently, and that the product meets the required specifications. Some of the key job responsibilities of a First Crusher include:

1. Operating and maintaining crushers

First Crushers are responsible for operating and maintaining crushers, which are used to break down large rocks into smaller pieces. They must ensure that the crushers are running smoothly and efficiently, and that the product meets the required specifications.

- Starting and stopping crushers

- Adjusting crusher settings

- Monitoring crusher performance

- Performing routine maintenance on crushers

2. Troubleshooting and repairing crushers

First Crushers must be able to troubleshoot and repair crushers when they break down. They must be able to identify the problem, and then take the necessary steps to fix it.

- Identifying crusher problems

- Repairing crusher parts

- Replacing crusher parts

3. Maintaining a safe work environment

First Crushers must maintain a safe work environment for themselves and others. They must follow all safety procedures, and wear the appropriate safety gear.

- Following safety procedures

- Wearing the appropriate safety gear

- Keeping the work area clean and tidy

4. Other duties

First Crushers may also be required to perform other duties, such as:

- Loading and unloading materials

- Operating other equipment

- Assisting other workers

Interview Tips

Following are some tips on how to prepare for and ace your interview for a First Crusher position:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position. This will help you answer questions intelligently and show that you’re interested in the job. You can find information about the company on their website, in their annual report, or in news articles.

2. Practice answering common interview questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Take some time to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

3. Be prepared to talk about your experience

The interviewer will likely ask you about your experience operating and maintaining crushers. Be prepared to talk about your skills and knowledge in this area. You can also mention any relevant experience you have, such as working on a construction crew or in a manufacturing plant.

4. Dress professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting.

5. Be on time

Punctuality is important for any job interview, but it’s especially important for a First Crusher position. This shows that you’re reliable and that you can be counted on to meet deadlines.

6. Be confident

Confidence is key in any job interview. Believe in yourself and your abilities, and let the interviewer know that you’re the best person for the job.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a First Crusher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for First Crusher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.