Are you gearing up for an interview for a Glass Grinder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Glass Grinder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

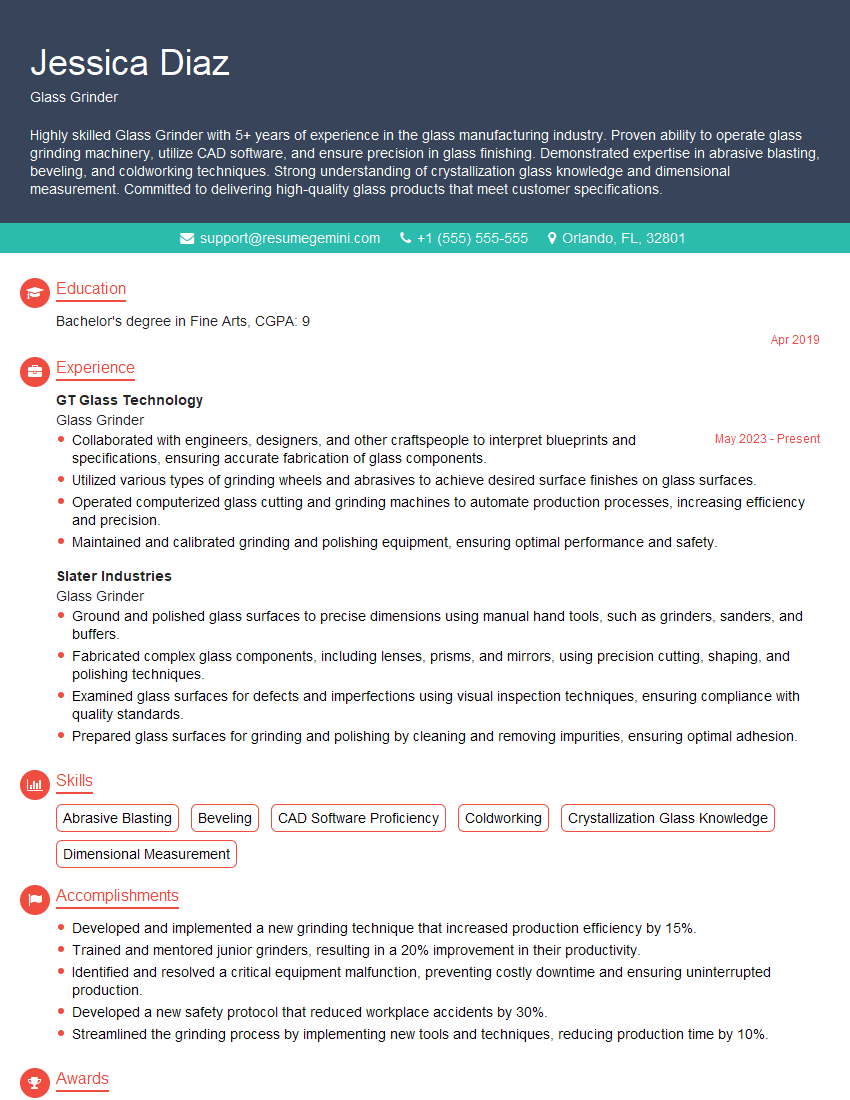

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glass Grinder

1. What are the different types of glass grinding machines and their applications?

There are various types of glass grinding machines used for different applications. Some common types include:

- Edge grinders: Used for grinding and shaping the edges of glass panels, creating bevels, miters, or other decorative profiles.

- Surface grinders: Designed for grinding and smoothing the surface of glass, removing scratches, imperfections, or creating a specific texture.

- CNC grinders: Computer-controlled machines that allow for precise grinding of complex shapes, patterns, and designs.

- Glass drilling machines: Used for drilling holes or creating cutouts in glass for hardware, fittings, or decorative purposes.

2. How do you select the appropriate grinding wheel for a specific glass grinding application?

Factors to consider:

- Glass type: Different types of glass (e.g., annealed, tempered, laminated) require specific grinding wheels to ensure optimal performance and safety.

- Grinding operation: The intended grinding task (e.g., rough grinding, fine polishing) determines the appropriate wheel grit and composition.

- Machine and workpiece size: The size and speed of the grinding machine, as well as the size and shape of the workpiece, influence the wheel selection.

- Desired finish: The desired surface finish or texture of the glass requires careful consideration of the grinding wheel properties.

3. Describe the process of setting up and operating a glass grinding machine safely.

- Machine preparation: Ensure the machine is securely mounted, properly leveled, and all safety guards are in place.

- Glass preparation: Clean and inspect the glass for any cracks or imperfections. Securely clamp or fixture the glass to prevent movement during grinding.

- Grinding wheel selection: Select the appropriate grinding wheel based on the glass type and grinding operation.

- Machine setup: Adjust the grinding head, wheel speed, and coolant flow rate as per the manufacturer’s recommendations.

- Safety precautions: Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a respirator if necessary.

4. How do you identify and resolve common problems that occur during glass grinding?

- Excessive heat generation: Adjust the grinding speed, coolant flow, or use a different grinding wheel to reduce heat.

- Glass cracking: Inspect the glass for cracks before grinding. Use a sharp grinding wheel and avoid excessive pressure.

- Poor surface finish: Choose a finer grit grinding wheel or adjust the grinding speed and pressure to achieve the desired finish.

- Machine vibrations: Ensure the machine is properly leveled and balanced. Check for loose parts or worn components.

- Coolant system issues: Inspect the coolant system for leaks, clogs, or low fluid levels. Ensure the coolant flow is sufficient to prevent overheating.

5. What techniques can be used to create complex shapes and designs in glass using grinding machines?

- CNC programming: Use CNC machines with specialized software to create precise and intricate shapes.

- Jigs and fixtures: Design and use jigs or fixtures to guide the grinding head for specific shapes or patterns.

- Handheld grinders: Use handheld grinders with various attachments to create freehand designs or smooth curves.

- Templating: Create templates or stencils to guide the grinding operations for consistent shapes.

6. How do you ensure the accuracy and precision of glass grinding operations?

- Machine calibration: Regularly calibrate the grinding machine and its components to maintain accuracy.

- Precise measurement: Use precision measuring tools to ensure the dimensions and shapes meet the specifications.

- Quality control: Implement quality control measures to inspect and verify the accuracy of the ground glass products.

- Operator training: Provide proper training to operators on the importance of precision and attention to detail.

7. What is the importance of using coolants in glass grinding operations?

- Reduce heat generation: Coolants prevent excessive heat buildup, which can damage the glass or cause thermal stress.

- Lubrication: Coolants act as lubricants, reducing friction between the grinding wheel and glass, resulting in smoother grinding.

- Clearance of debris: Coolants help flush away glass particles and debris from the grinding area, improving visibility and reducing clogging.

- Extended wheel life: Proper cooling helps extend the lifespan of grinding wheels by preventing premature wear and tear.

8. How do you maintain and troubleshoot glass grinding equipment?

- Regular inspections: Regularly inspect the machine, grinding wheels, and other components for signs of wear or damage.

- Preventive maintenance: Perform scheduled maintenance tasks, such as lubrication, belt tensioning, and coolant system cleaning.

- Troubleshooting: Identify and resolve common issues, such as machine vibrations, coolant leaks, or wheel imbalances.

- Calibration and repair: Calibrate the machine as needed and repair or replace faulty components to ensure optimal performance.

9. Describe the different types of safety measures and best practices in glass grinding operations.

- Personal protective equipment (PPE): Wear safety glasses, gloves, respiratory protection, and protective clothing.

- Guarding and enclosures: Ensure all moving parts are properly guarded to prevent contact with hands or clothing.

- Ventilation: Provide adequate ventilation to remove glass dust and other airborne particles.

- Proper handling and storage: Safely handle glass panels, use appropriate lifting equipment, and store glass in designated areas.

- Training: Provide comprehensive training to operators on safety protocols and proper equipment use.

10. What quality control checks are performed on ground glass products, and how do you ensure their adherence to specifications?

- Dimensional accuracy: Verify the dimensions and shapes of ground glass products using precision measuring tools.

- Surface quality: Inspect the surface for scratches, cracks, or other defects using visual or automated inspection methods.

- Edge quality: Check the edges for proper shape, smoothness, and absence of chipping or breakage.

- Optical clarity: For optical applications, inspect the glass for clarity, distortion, or any optical imperfections.

- Quality control documentation: Maintain detailed records of quality control checks to ensure traceability and compliance with specifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glass Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glass Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Glass Grinders are responsible for shaping and smoothing glass surfaces to meet specific requirements. They operate specialized machinery to grind, polish, and bevel glass pieces.

1. Grinding

Grinding glass involves removing excess material to achieve the desired shape and thickness.

- Operate grinding machines to remove glass material

- Control grinding speed, pressure, and angle to create specific shapes

2. Polishing

Polishing smooths and refines the surface of glass to minimize imperfections.

- Use polishing wheels and abrasives to remove scratches and create a smooth surface

- Control polishing pressure and speed to achieve desired finish

3. Beveling

Beveling creates angled edges on glass surfaces for aesthetic or functional purposes.

- Operate beveling machines to create angled edges

- Control bevel angle and depth to achieve desired effect

4. Quality Control

Inspecting and measuring glass surfaces to ensure they meet specifications.

- Inspect glass for defects, scratches, and imperfections

- Measure glass thickness, angles, and dimensions to ensure accuracy

Interview Tips

To prepare for a Glass Grinder interview, focus on demonstrating your technical skills, attention to detail, and commitment to producing high-quality glass products.

1. Research the Company and Position

Learn about the company’s products, services, and industry reputation. Review the job description carefully to understand the specific requirements and responsibilities of the role.

- Visit the company website and social media pages

- Read industry publications and articles

- Identify any relevant skills or experience that you possess

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful responses that highlight your qualifications. Practice your answers aloud to improve your delivery and confidence.

- Describe your experience with glass grinding, polishing, and beveling

- Explain how you ensure accuracy and precision in your work

- Discuss your knowledge of safety procedures and industry standards

3. Be Prepared to Discuss Your Skills

Emphasize your technical abilities, such as your proficiency in operating grinding, polishing, and beveling machines. Highlight your attention to detail, problem-solving skills, and ability to work independently and as part of a team.

- Provide specific examples of projects where you successfully used your skills

- Quantify your accomplishments whenever possible, using metrics or data

- Explain how your skills can benefit the company

4. Show Your Enthusiasm

Express your passion for glassworking and your desire to contribute to the company’s success. Highlight your commitment to producing high-quality work and your eagerness to learn and grow in the industry.

- Explain why you are interested in the glass grinding profession

- Share your knowledge of glassworking techniques and industry trends

- Convey your excitement about the opportunity to work for the company

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Glass Grinder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.