Feeling lost in a sea of interview questions? Landed that dream interview for Glaze Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Glaze Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

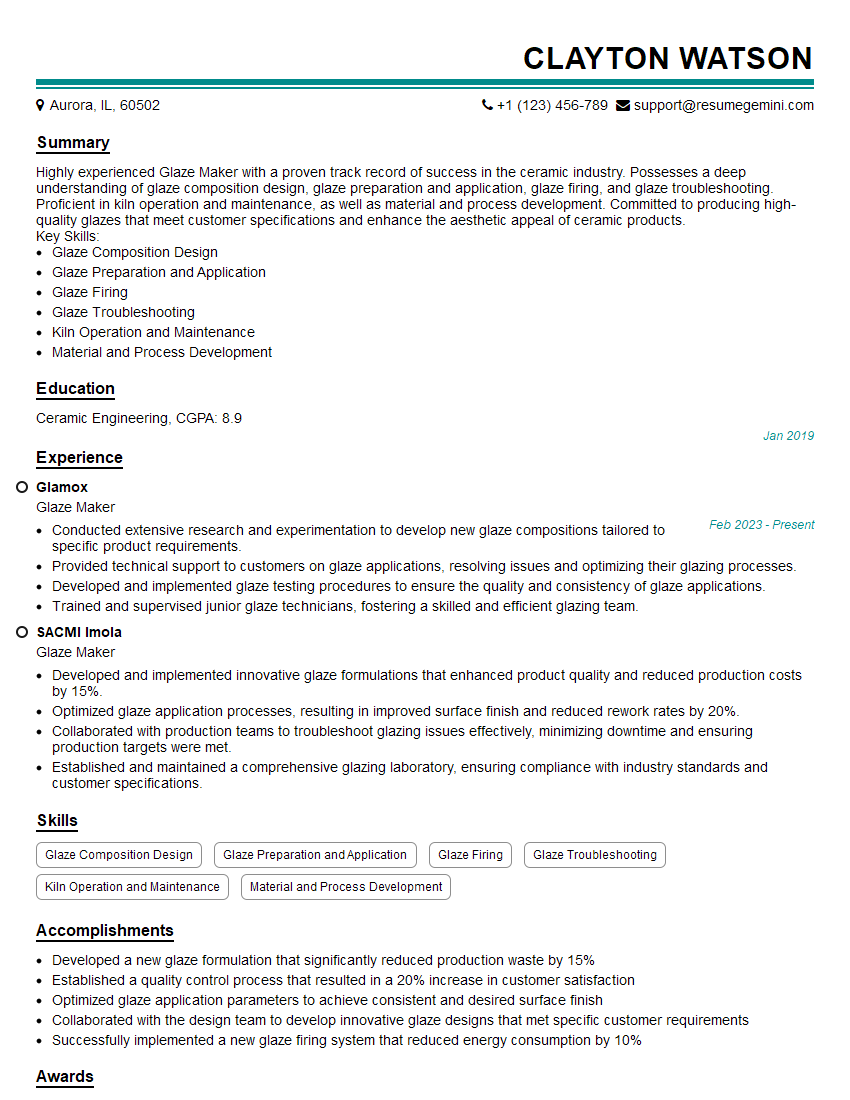

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Glaze Maker

1. Explain the process of glaze preparation?

The process of glaze preparation involves several steps, including:

- Raw material selection: Choosing the appropriate raw materials based on the desired glaze properties.

- Weighing and mixing: Accurately weighing and mixing the raw materials to achieve the desired glaze composition.

- Milling: Grinding the raw materials into a fine powder to ensure uniform particle size and enhance glaze properties.

- Mixing with water: Suspending the glaze powder in water to create a workable consistency.

- Screening: Removing any impurities or agglomerates from the glaze suspension using a sieve or filter.

- Aging: Allowing the glaze to age for a period of time, which promotes hydration and improves glaze stability.

2. What are the different types of glazes used in the ceramic industry?

Earthenware Glazes

- Lead glazes

- Lead-free glazes

- Salt glazes

Stoneware Glazes

- Feldspathic glazes

- Celadon glazes

- Ash glazes

Porcelain Glazes

- High-fire glazes

- Low-fire glazes

- Celadon glazes

3. How do you control the viscosity of a glaze?

The viscosity of a glaze can be controlled by adjusting the following factors:

- Water content: Increasing the water content will decrease the viscosity, making the glaze thinner.

- Clay content: Adding clay to the glaze will increase the viscosity, making the glaze thicker.

- Additives: Certain additives, such as gums or bentonite, can be added to the glaze to increase its viscosity.

- Temperature: The temperature at which the glaze is applied can also affect its viscosity, with higher temperatures generally resulting in a lower viscosity.

4. What are the common defects that can occur in glazes?

There are several common defects that can occur in glazes, including:

- Crawling: The glaze pulls away from the ceramic surface, leaving bare areas.

- Pinholing: Small holes or bubbles appear in the glaze surface.

- Crazing: Fine cracks appear in the glaze surface.

- Blistering: Blisters or bubbles form on the glaze surface.

- Deviation: The glaze does not adhere to the ceramic surface properly, resulting in a non-uniform appearance.

5. How do you troubleshoot and correct glaze defects?

Troubleshooting and correcting glaze defects involves identifying the cause of the defect and implementing appropriate measures to resolve it. Common troubleshooting steps include:

- Examining the glaze composition: Checking for any errors or imbalances in the glaze formula.

- Adjusting the application process: Modifying the glaze thickness, application method, or firing conditions.

- Testing different glaze materials: Trying alternative raw materials or glaze additives to improve glaze properties.

- Consulting with glaze experts: Seeking advice from experienced glaze makers or researchers.

6. What are the safety precautions you should take when working with glazes?

When working with glazes, it is essential to follow these safety precautions:

- Wear appropriate protective gear: Gloves, a mask, and eye protection.

- Ensure proper ventilation: Work in a well-ventilated area to minimize exposure to dust or fumes.

- Handle glazes carefully: Avoid spilling or splattering glazes, and clean up any spills immediately.

- Dispose of glazes properly: Do not pour glazes down the drain or dispose of them in landfills. Follow local regulations for proper disposal.

- Stay informed about glaze safety: Keep up-to-date on the latest safety guidelines and research related to glazes.

7. How do you stay updated on the latest developments in glaze technology?

To stay updated on the latest developments in glaze technology, I employ the following strategies:

- Attending workshops and conferences: Participating in industry events where experts share their knowledge and research.

- Reading industry publications: Subscribing to journals and online resources that cover glaze technology advancements.

- Networking with other glaze makers: Connecting with fellow professionals through organizations and forums to exchange ideas and learn about new techniques.

- Conducting research: Exploring scientific papers and studies to stay informed about the latest findings in glaze chemistry and application.

8. What are the qualities of a successful glaze maker?

A successful glaze maker possesses the following qualities:

- Technical expertise: A deep understanding of glaze chemistry, raw materials, and application techniques.

- Creative vision: The ability to develop original and aesthetically pleasing glazes.

- Problem-solving skills: The capability to identify and resolve glaze defects, ensuring the production of high-quality glazed ceramics.

- Attention to detail: A meticulous approach to glaze preparation, application, and firing to achieve consistent and desired results.

- Commitment to safety: A strong adherence to safety protocols, ensuring the well-being of oneself and others while working with glazes.

9. What are the challenges you have faced in your previous experience as a glaze maker?

In my previous experience, I have encountered the following challenges as a glaze maker:

- Developing glazes with specific properties: Meeting the unique requirements of different ceramic applications, such as achieving a desired color, texture, or durability.

- Troubleshooting glaze defects: Identifying and resolving glaze defects, such as crawling, pinholing, or crazing, to ensure the production of high-quality glazed ceramics.

- Optimizing glaze application techniques: Determining the best application methods, glaze thickness, and firing conditions to achieve the desired glaze effects.

- Staying updated with advancements in glaze technology: Keeping pace with the latest research and developments in glaze chemistry and application to enhance my skills and knowledge.

10. How do you incorporate sustainability into your glaze making practices?

I incorporate sustainability into my glaze making practices through the following measures:

- Using eco-friendly raw materials: Selecting raw materials that are sustainably sourced and minimize environmental impact.

- Reducing waste: Optimizing glaze preparation and application techniques to minimize waste and conserve resources.

- Recycling and reusing glaze materials: Repurposing glaze leftovers and reclaiming materials from glaze defects to reduce waste.

- Exploring alternative firing methods: Investigating energy-efficient firing techniques, such as electric kilns or alternative fuels, to minimize carbon emissions.

- Promoting sustainable glaze practices: Sharing knowledge and best practices with other glaze makers and ceramicists to encourage the adoption of sustainable approaches.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Glaze Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Glaze Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Glaze Makers play a pivotal role in the ceramic industry, responsible for developing and producing high-quality glazes used in various applications, including tableware, decorative tiles, and industrial ceramics. Their key job responsibilities include:

1. Glaze Development and Formulation

Develop and formulate new glaze compositions to meet specific aesthetic, functional, and application requirements. Conduct research and testing to optimize glaze properties such as color, texture, opacity, and durability.

2. Glaze Application and Testing

Apply glazes to ceramic substrates using various techniques, such as dipping, spraying, or brushing. Test glazed products for adherence, color consistency, and resistance to wear and tear.

3. Glaze Production and Maintenance

Monitor and control glaze production processes to ensure quality and efficiency. Maintain glaze storage, mixing, and application equipment in optimal condition.

4. Troubleshooting and Quality Control

Identify and resolve glaze-related issues promptly. Monitor glaze quality throughout the production process and make adjustments as needed.

Interview Tips

To ace the Glaze Maker interview, consider these preparation tips:

1. Research the Company and Industry

Familiarize yourself with the company’s ceramic products, manufacturing processes, and customer base. Research industry trends and advancements in glaze technology.

2. Highlight Relevant Experience and Skills

Emphasize your experience in glaze development, application, and testing. Showcase your ability to work independently and as part of a team.

3. Prepare Examples of Successful Glaze Projects

Provide specific examples of glaze projects you’ve worked on, outlining your contributions and the results achieved. Highlight your creativity, attention to detail, and problem-solving skills.

4. Demonstrate Understanding of Glaze Chemistry

Explain your understanding of glaze chemistry, including the role of different raw materials and firing conditions in glaze development. Discuss your experience in troubleshooting glaze defects.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Glaze Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!