Are you gearing up for an interview for a Grinding Mill Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Grinding Mill Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

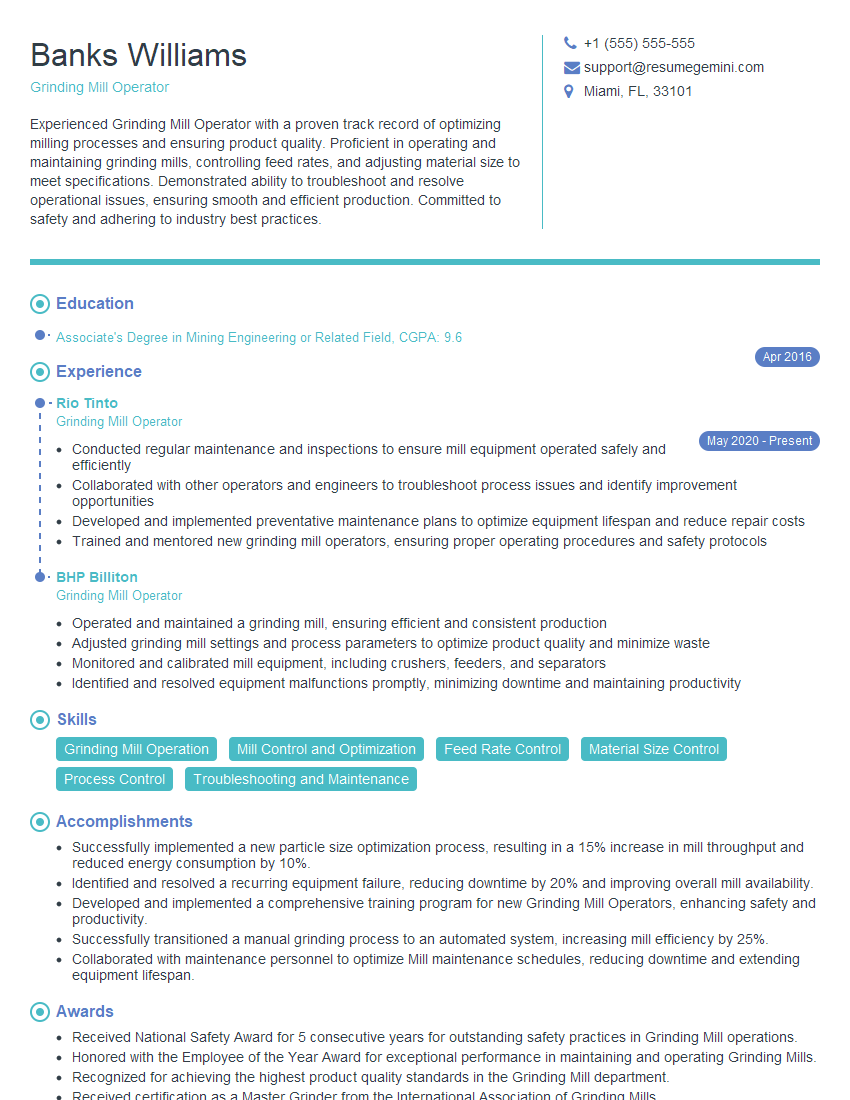

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grinding Mill Operator

1. How do you determine the optimal feed rate for a grinding mill?

To determine the optimal feed rate for a grinding mill, I consider several factors:

- Material properties: The size, shape, and hardness of the material impact the feed rate.

- Mill type: Different grinding mills (e.g., ball mill, rod mill) have varying feed rate requirements.

- Mill size: Larger mills can handle higher feed rates.

- Desired grind size: Finer grind sizes require slower feed rates.

- Power consumption: Exceeding the optimal feed rate can increase power consumption.

2. Explain how you monitor and control the temperature of the grinding chamber.

Temperature Measurement:

- Utilize temperature sensors installed within the grinding chamber.

- Monitor the temperature readings and compare them to established limits.

Temperature Control:

- Adjust the feed rate to regulate the heat generated by grinding.

- Control the cooling system (e.g., water jackets) to dissipate heat.

- Monitor the lubrication system to ensure proper lubrication and prevent overheating.

3. Describe the maintenance procedures you follow to ensure the efficient operation of a grinding mill.

- Regular inspections: Visual inspections of mill components, including bearings, liners, and grates.

- Lubrication: Maintaining proper lubrication of all moving parts to reduce friction and wear.

- Wear monitoring: Tracking wear on liners, grates, and balls to determine replacement intervals.

- Alignment checks: Verifying the alignment of mill components to prevent vibration and damage.

- Electrical maintenance: Inspecting and servicing electrical components, such as motors and drives.

4. How do you troubleshoot common problems that occur in a grinding mill operation?

When troubleshooting common problems in grinding mill operations, I follow a systematic approach:

- Identify the problem: Observation, data analysis, and consultations with colleagues.

- Analyze potential causes: Consider factors such as feed material, mill conditions, and operational parameters.

- Implement solutions: Test and apply appropriate corrective actions based on the analysis.

- Monitor results: Track the effectiveness of solutions and make adjustments as needed.

5. Explain the importance of safety precautions when operating a grinding mill.

- Protective gear: Wearing appropriate safety gear (e.g., earplugs, hard hat, gloves) to minimize risks.

- Lockout/tagout procedures: Following established procedures to prevent accidental equipment activation during maintenance.

- Area monitoring: Continuously monitoring the surrounding area for potential hazards.

- Emergency response plan: Familiarizing oneself with emergency response protocols to handle incidents effectively.

- Training and certification: Receiving proper training and certifications to ensure safe operation.

6. Describe the quality control procedures you use to ensure the desired product size is achieved.

- Particle size analysis: Regularly collecting samples and conducting particle size analysis using sieving or laser diffraction techniques.

- Adjustments to mill settings: Modifying mill operating parameters (e.g., speed, feed rate) based on particle size analysis results.

- Process monitoring: Continuously monitoring process variables (e.g., temperature, power consumption) that impact particle size.

- Data recording and analysis: Maintaining records of particle size data and analyzing trends to identify improvement areas.

7. How do you optimize the grinding process to minimize energy consumption?

- Feed rate optimization: Determining the optimal feed rate to achieve maximum grinding efficiency while minimizing power consumption.

- Media selection: Selecting grinding media (e.g., balls, rods) that are appropriate for the material being ground and the desired particle size.

- Mill speed control: Adjusting mill speed to balance grinding efficiency and energy consumption.

- Monitoring and control: Continuously monitoring process variables (e.g., temperature, power consumption) and making adjustments as needed.

8. Explain your experience in selecting and installing grinding mill liner materials.

In my previous role, I was responsible for selecting and installing grinding mill liner materials. I considered several factors:

- Material properties: The hardness, wear resistance, and corrosion resistance of the liner material.

- Mill type and size: The type and size of the grinding mill impact the liner design and installation.

- Material being ground: The abrasive properties of the material being ground influence the liner material selection.

- Installation techniques: Proper installation techniques, such as welding or bolting, are crucial for liner performance.

9. Describe your approach to training and mentoring new grinding mill operators.

- On-the-job training: Providing hands-on experience and guidance while operating grinding mills.

- Classroom instruction: Delivering formal training sessions on grinding mill principles, safety procedures, and troubleshooting.

- Assessment and feedback: Regularly assessing trainees’ progress and providing constructive feedback.

- Mentorship program: Pairing new operators with experienced mentors for guidance and support.

10. How do you stay up-to-date with the latest advancements in grinding mill technology?

- Industry publications: Regularly reading trade journals and research papers on grinding mill technology.

- Conferences and seminars: Attending industry conferences and seminars to learn about new equipment and processes.

- Manufacturer training: Participating in training programs offered by grinding mill manufacturers.

- Networking with colleagues: Sharing knowledge and experiences with other grinding mill operators and professionals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grinding Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grinding Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Grinding Mill Operators are responsible for the operation and maintenance of grinding mills, which are used to reduce the size of materials. They must ensure that the mills are operating safely and efficiently, and that the materials are being ground to the desired specification.

1. Operate Grinding Mills

Grinding Mill Operators must be able to operate grinding mills of various types and sizes. They must be able to adjust the mill settings to achieve the desired product size and quality.

- Start and stop the mill.

- Adjust the mill settings to achieve the desired product size and quality.

- Monitor the mill’s operation and make adjustments as needed.

2. Maintain Grinding Mills

Grinding Mill Operators must be able to maintain grinding mills in good working order. They must be able to identify and repair common problems, and they must be able to perform routine maintenance tasks.

- Inspect the mill for wear and tear.

- Replace worn parts.

- Lubricate the mill.

- Clean the mill.

3. Ensure Safety

Grinding Mill Operators must be able to ensure the safety of themselves and others when working with grinding mills. They must be aware of the potential hazards associated with grinding mills, and they must take the necessary precautions to avoid accidents.

- Wear appropriate safety gear.

- Follow all safety procedures.

- Identify and report any potential hazards.

4. Work with Others

Grinding Mill Operators must be able to work with others in a team environment. They must be able to communicate effectively with other team members, and they must be able to work together to resolve problems.

- Communicate with other team members.

- Work together to resolve problems.

- Train new employees.

Interview Tips

In addition to being able to perform the key job responsibilities, there are a few things that you can do to prepare for an interview for a Grinding Mill Operator position.

1. Research the Company

Before you go on an interview, it is important to research the company that you are applying to. This will help you to understand the company’s culture and values, and it will also help you to answer questions about the company during the interview.

- Visit the company’s website.

- Read about the company in the news.

- Talk to people who work for the company.

2. Practice Answering Interview Questions

It is also important to practice answering interview questions. This will help you to feel more confident during the interview, and it will also help you to give better answers. There are a number of resources available online that can help you to practice answering interview questions.

- Use a mock interview website.

- Ask a friend or family member to interview you.

- Practice answering interview questions in front of a mirror.

3. Dress Professionally

It is important to dress professionally for an interview. This will show the interviewer that you are serious about the job, and it will also make a good impression.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Wear comfortable shoes.

4. Be On Time

It is important to be on time for your interview. This will show the interviewer that you are respectful of their time, and it will also make a good impression.

- Plan your route in advance.

- Leave early to allow for unexpected delays.

- Call the interviewer if you are going to be late.

Next Step:

Now that you’re armed with the knowledge of Grinding Mill Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Grinding Mill Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini