Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gristmill Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

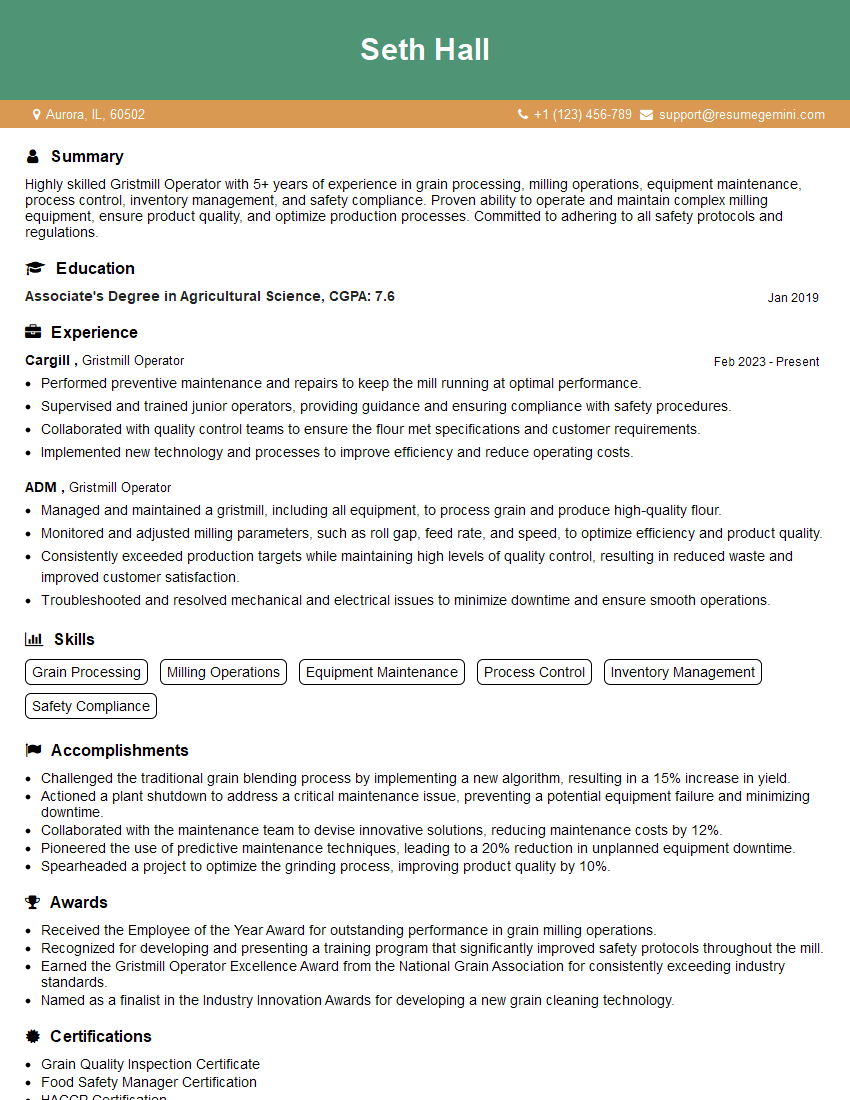

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gristmill Operator

1. How would you ensure the efficient operation of the gristmill, including the maintenance and calibration of equipment?

To ensure efficient gristmill operation, I would:

- Regularly inspect and maintain all equipment, including grinders, sifters, and conveyors.

- Calibrate equipment to ensure accurate measurements and consistent product quality.

- Monitor equipment performance and make adjustments as needed.

2. What are the key safety precautions to observe when operating a gristmill?

Safe Material Handling

- Wear appropriate protective gear.

- Handle grain and flour carefully to avoid spills and dust inhalation.

Machine Safety

- Keep hands and loose clothing away from moving parts.

- Do not operate equipment with missing or damaged safety guards.

Electrical Safety

- Use lockout/tagout procedures when performing maintenance.

- Avoid contact with electrical components.

3. How would you troubleshoot and resolve common gristmill malfunctions?

Troubleshooting gristmill malfunctions involves:

- Identifying the malfunction’s symptoms.

- Checking for common causes such as equipment failure, incorrect settings, or operator error.

- Consulting maintenance manuals or seeking assistance from experienced millers.

- Implementing appropriate corrective actions.

4. How do you ensure the quality of the finished product, including grain cleaning and sifting?

To ensure finished product quality, I would:

- Clean the grain thoroughly to remove impurities.

- Sift the flour to remove bran and other undesirable particles.

- Monitor the grinding process to ensure consistent particle size.

- Conduct regular quality checks to meet specifications.

5. What is the role of moisture content in the grinding process, and how do you adjust it?

Moisture content significantly impacts grinding efficiency and product quality. To adjust it:

- Measure the moisture content of the grain using a moisture meter.

- Add water or dry grain to achieve the desired moisture level.

- Monitor the grinding process and make adjustments as needed.

6. How do you optimize the grinding process to achieve desired flour yields and particle size distribution?

Optimizing grinding involves:

- Adjusting grinder settings for particle size control.

- Selecting appropriate grinding plates or cutters.

- Monitoring the grinding rate and adjusting it to achieve desired yields.

- Sifting the flour to obtain the desired particle size distribution.

7. How do you maintain a clean and sanitary work environment in the gristmill?

Maintaining a clean and sanitary work environment is crucial for food safety and quality:

- Regularly clean all equipment and work surfaces.

- Implement pest control measures to prevent contamination.

- Follow proper sanitation protocols to minimize the risk of cross-contamination.

8. How do you work effectively in a team setting and communicate with colleagues and supervisors?

Effective teamwork and communication involve:

- Cooperating with colleagues to achieve common goals.

- Sharing information and ideas to improve processes.

- Communicating clearly and respectfully with supervisors and colleagues.

9. What are your goals for working as a Gristmill Operator, and how do you plan to contribute to our organization?

My goals as a Gristmill Operator are:

- To maintain a safe and efficient work environment.

- To produce high-quality products that meet customer specifications.

- To contribute to the success of the organization through my skills and experience.

10. How would you handle a situation where you are required to operate a gristmill with limited resources or under time constraints?

In situations with limited resources or time constraints, I would:

- Prioritize tasks based on importance.

- Seek assistance from colleagues or supervisors when needed.

- Work efficiently and effectively to meet deadlines while maintaining quality standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gristmill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gristmill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Gristmill Operator is responsible for overseeing the operation, maintenance, and repair of a gristmill or flour mill. They ensure that the mill is running efficiently and producing high-quality products.

1. Operations

The Gristmill Operator is responsible for:

- Starting, stopping, and adjusting the mill’s machinery.

- Monitoring the mill’s operations to ensure that it is running smoothly and efficiently.

- Making adjustments to the mill’s settings to optimize production.

- Inspecting and cleaning the mill’s equipment to ensure that it is in good working order.

2. Maintenance

The Gristmill Operator is responsible for:

- Performing routine maintenance on the mill’s equipment.

- Troubleshooting and repairing any problems that may arise with the mill’s equipment.

- Maintaining a clean and organized work area.

3. Quality Control

The Gristmill Operator is responsible for:

- Monitoring the quality of the mill’s products.

- Making adjustments to the mill’s settings to improve the quality of the products.

- Inspecting the mill’s products to ensure that they meet the required standards.

4. Health and Safety

The Gristmill Operator is responsible for:

- Following all safety procedures and regulations.

- Maintaining a safe and healthy work environment.

- Reporting any safety hazards to the supervisor.

Interview Tips

Preparing for an interview for a Gristmill Operator position can be daunting, but with the right strategies, you can increase your chances of acing it.

1. Research the Company and the Position

Take the time to research the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture, values, and what they’re looking for in a candidate. You can find this information on the company’s website, social media pages, and Glassdoor.

2. Practice Your Answers

Once you have a good understanding of the company and the position, you can start practicing your answers to common interview questions. This will help you feel more confident and prepared during the interview.

3. Highlight Your Skills and Experience

Make sure to highlight your skills and experience that are relevant to the Gristmill Operator position. This includes your experience with operating and maintaining gristmills, your knowledge of quality control procedures, and your commitment to safety.

4. Be Enthusiastic and Positive

The interviewer wants to see that you’re excited about the position and that you’re a positive and enthusiastic person. Be sure to smile, make eye contact, and be yourself.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Gristmill Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Gristmill Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.