Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lens Grinding Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

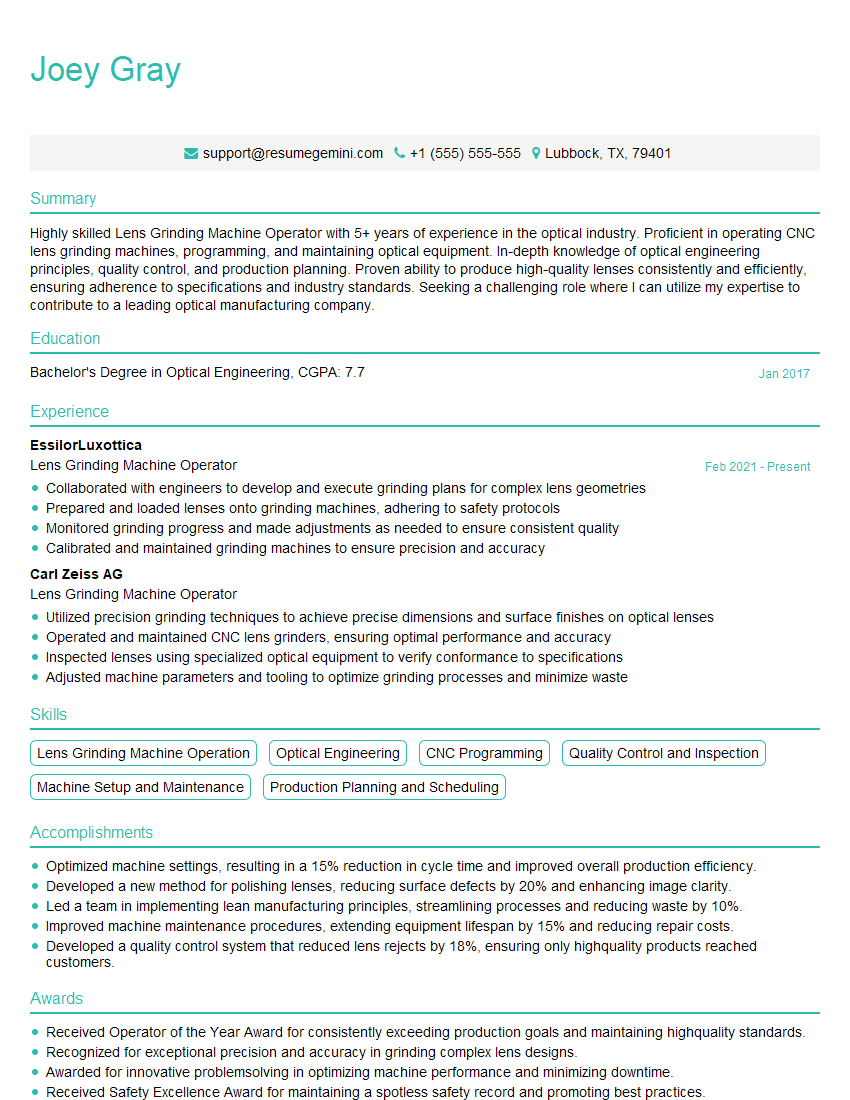

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lens Grinding Machine Operator

1. What are the different types of lens grinding machines?

There are three main types of lens grinding machines:

- Single-wheel machines

- Multiple-wheel machines

- CNC machines

2. What are the key components of a lens grinding machine?

The main components of a lens grinding machine are:

- The grinding wheel

- The workpiece holder

- The drive system

- The control system

The grinding wheel is the most important component of the machine. It is made of a hard, abrasive material, such as diamond or CBN.

- The workpiece holder holds the lens in place during the grinding process.

- The drive system rotates the grinding wheel and the workpiece.

- The control system monitors the grinding process and ensures that the lens is ground to the correct specifications.

3. What are the different types of grinding wheels used in lens grinding?

The three main types of grinding wheels used in lens grinding are:

- Diamond grinding wheels

- CBN grinding wheels

- Ceramic grinding wheels

Diamond grinding wheels are the most expensive but also the most durable. CBN grinding wheels are a good compromise between price and durability. Ceramic grinding wheels are the least expensive but also the least durable.

4. What are the different types of workpiece holders used in lens grinding?

The two main types of workpiece holders used in lens grinding are:

- Manual workpiece holders

- CNC workpiece holders

Manual workpiece holders are used to hold the lens in place during the grinding process. CNC workpiece holders are used to hold the lens in place and also to rotate the lens during the grinding process.

5. What are the different types of drive systems used in lens grinding machines?

The two main types of drive systems used in lens grinding machines are:

- Mechanical drive systems

- Hydraulic drive systems

Mechanical drive systems use a series of gears and pulleys to rotate the grinding wheel and the workpiece. Hydraulic drive systems use a hydraulic pump to rotate the grinding wheel and the workpiece.

6. What are the different types of control systems used in lens grinding machines?

The two main types of control systems used in lens grinding machines are:

- Manual control systems

- CNC control systems

Manual control systems are used to control the grinding process manually. CNC control systems are used to control the grinding process automatically.

7. What are the safety precautions that must be taken when operating a lens grinding machine?

The following safety precautions must be taken when operating a lens grinding machine:

- Wear eye protection.

- Wear ear protection.

- Wear respiratory protection.

- Keep the machine clean and free of debris.

- Do not operate the machine if you are tired or under the influence of drugs or alcohol.

8. What are the maintenance procedures that must be performed on a lens grinding machine?

The following maintenance procedures must be performed on a lens grinding machine:

- Clean the machine daily.

- Lubricate the machine weekly.

- Inspect the grinding wheel monthly.

- Replace the grinding wheel when it is worn out.

- Calibrate the machine annually.

9. What are the troubleshooting procedures for a lens grinding machine?

The following troubleshooting procedures can be used to troubleshoot a lens grinding machine:

- Check the power supply.

- Check the grinding wheel.

- Check the workpiece holder.

- Check the drive system.

- Check the control system.

10. What are the quality control procedures for a lens grinding machine?

The following quality control procedures can be used to ensure that the lenses produced by a lens grinding machine meet the required specifications:

- Inspect the lenses visually.

- Measure the lenses using a lensometer.

- Test the lenses in a lens tester.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lens Grinding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lens Grinding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lens Grinding Machine Operators are responsible for grinding and polishing lenses for eyeglasses, camera lenses, and other optical devices using specialized machinery.

1. Machine Operation

Skilled Lens Grinding Machine Operators program, set up, and operate CNC-controlled lens grinding and polishing machines precisely.

- Conduct regular maintenance and troubleshoot any operational issues with ease.

- Ensure that finished lenses meet specified tolerances and quality standards.

2. Lens Processing

Experts in Lens Processing handle various types of raw lenses, including glass, plastic, and polycarbonate lenses.

- Cylindrical or spherical grinding of lenses based on specific prescriptions.

- Properly position and secure lenses for grinding and polishing operations.

3. Quality Control

Quality Control is an integral aspect of a Lens Grinding Machine Operator’s role.

- Inspect lenses thoroughly for defects and imperfections.

- Measure and verify lens dimensions and surface quality to ensure accuracy.

4. Safety and Compliance

Safety and Compliance are paramount for Lens Grinding Machine Operators.

- Adhere to established safety protocols and wear appropriate personal protective equipment.

- Maintain a clean and organized work area, promoting both safety and efficiency.

Interview Tips

To ace your interview for a Lens Grinding Machine Operator position, meticulous preparation is vital.

1. Research and Preparation

Thorough research is key. Learn about the company, the specific role, and the industry as a whole.

- Practice answering common interview questions and prepare thoughtful questions to ask the interviewer.

- Highlight your relevant skills and experience, especially if you have prior experience operating lens grinding machines.

2. Technical Knowledge

Demonstrate your understanding of lens grinding principles, machine operations, and quality control procedures.

- Provide examples of your proficiency in using CNC machines and measuring tools.

- Explain your knowledge of different types of lenses, grinding techniques, and polishing methods.

3. Safety and Attention to Detail

Emphasize your commitment to safety and attention to detail.

- Describe your experience with safety protocols and how you ensure a safe work environment.

- Highlight your ability to focus on precision and accuracy in your work.

4. Problem-Solving and Teamwork

Showcase your problem-solving skills and ability to work in a team environment.

- Share examples of how you have successfully resolved technical issues with lens grinding equipment.

- Describe your experience working effectively with colleagues in a manufacturing setting.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lens Grinding Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!