Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Machine Buffer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

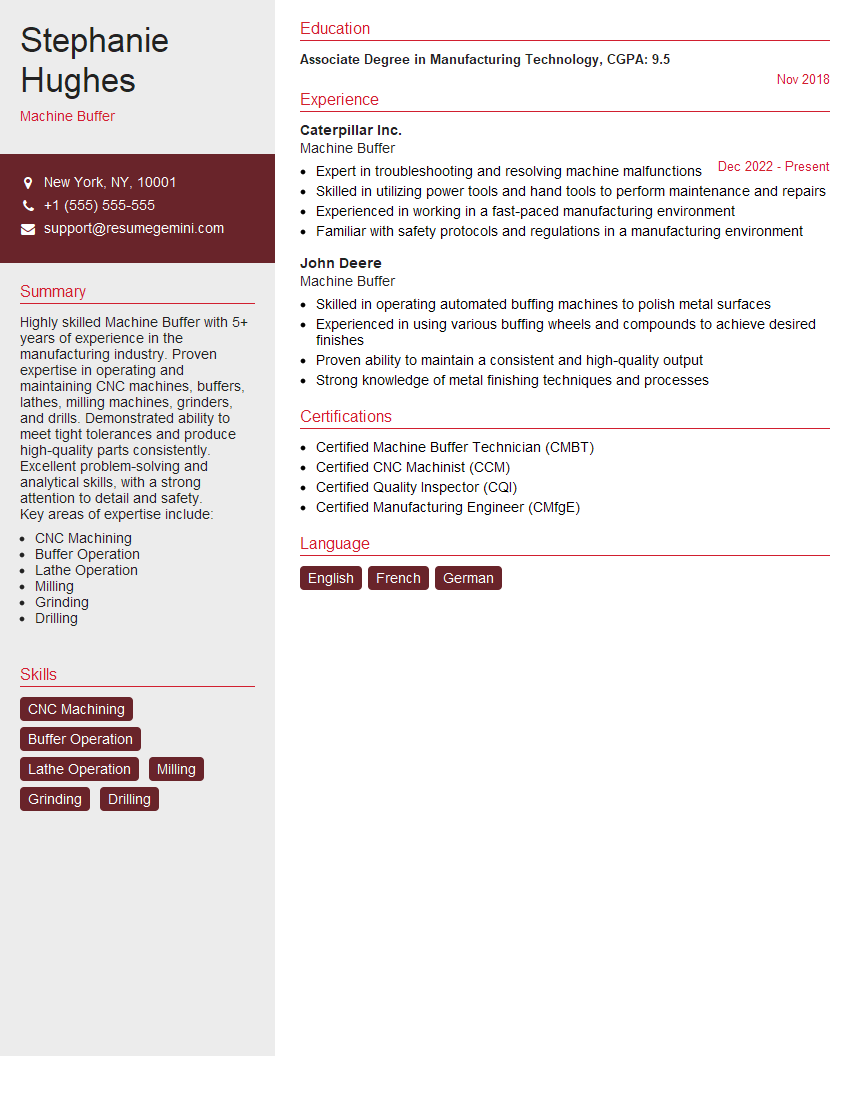

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Buffer

1. Explain the process of buffing a surface?

- Mount the appropriate buffing wheel on the machine.

- Apply the correct amount of buffing compound to the wheel.

- Place the workpiece against the buffing wheel and hold it firmly.

- Move the workpiece across the wheel in a smooth, even motion.

- Continue buffing until the desired finish is achieved.

2. What are the different types of buffing wheels?

- Sisal wheels are made from the fibers of the sisal plant and are used for heavy-duty buffing.

- Cotton wheels are made from cotton fibers and are used for medium-duty buffing.

- Felt wheels are made from wool fibers and are used for light-duty buffing.

- Buffing wheels can also be made from other materials, such as rubber, leather, or even wood.

3. What are the different types of buffing compounds?

- Cutting compounds are used to remove heavy scratches and imperfections from the surface of the workpiece.

- Polishing compounds are used to create a smooth, shiny finish on the workpiece.

- Buffing compounds can also be used to create specific effects, such as antiquing or satin.

4. What is the difference between buffing and polishing?

- Buffing is used to remove scratches and imperfections from the surface of the workpiece, while polishing is used to create a smooth, shiny finish.

- Buffing is typically done with a sisal or cotton wheel, while polishing is done with a felt or leather wheel.

- Buffing compounds are used to remove material from the surface of the workpiece, while polishing compounds are used to create a smooth, shiny finish.

5. What are the safety precautions that should be taken when buffing?

- Wear a dust mask to avoid inhaling dust particles.

- Wear safety glasses to protect your eyes from flying debris.

- Wear gloves to protect your hands from the buffing wheel.

- Keep your hair away from the buffing wheel to avoid it getting caught.

- Never buff a workpiece that is not securely clamped down.

6. What are the different techniques that can be used to buff a surface?

- Hand buffing is done using a handheld buffing machine.

- Bench buffing is done using a bench-mounted buffing machine.

- Automated buffing is done using a machine that automatically buffs the workpiece.

- The technique that is used depends on the size and shape of the workpiece, as well as the desired finish.

7. What are the different factors that can affect the quality of a buffed surface?

- The type of buffing wheel

- The type of buffing compound

- The speed of the buffing wheel

- The pressure applied to the workpiece

- The length of time the workpiece is buffed

8. What are the common troubleshooting tips for buffing?

- If the buffing wheel is not removing material, it may be necessary to use a more aggressive buffing compound.

- If the buffing wheel is leaving scratches on the workpiece, it may be necessary to use a less aggressive buffing compound or to reduce the speed of the buffing wheel.

- If the workpiece is not being buffed evenly, it may be necessary to adjust the pressure or the angle at which the workpiece is being held against the buffing wheel.

9. What are the different applications for buffing?

- Buffing can be used to remove scratches and imperfections from a variety of surfaces, such as metal, plastic, and wood.

- Buffing can also be used to create a smooth, shiny finish on a surface.

- Buffing can be used for a variety of applications, such as automotive detailing, metalworking, and woodworking.

10. What are the latest trends in buffing technology?

- The development of new buffing compounds that are more effective and less harmful to the environment.

- The development of new buffing wheels that are more durable and efficient.

- The development of new buffing machines that are more automated and user-friendly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Buffer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Buffer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Buffers are responsible for operating and maintaining machines used to buff and polish metal, plastic, and wood surfaces. They follow specific instructions and ensure that the surface finish meets the required standards. Key responsibilities include:

1. Machine Operation

Setting up the machine according to specifications, including speed, feed rate, and abrasive selection

- Loading and unloading workpieces

- Monitoring the buffing process to ensure the desired finish is achieved

2. Machine Maintenance

Performing routine maintenance on the buffing machines, including cleaning, lubrication, and minor repairs

- Adjusting and calibrating the machine to ensure accuracy and precision

- Troubleshooting and resolving minor issues

3. Quality Control

Inspecting the finished surfaces to ensure they meet the required standards

- Using measuring tools and gauges to verify dimensions and surface roughness

- Identifying and correcting any defects

4. Safety and Compliance

Following all safety protocols and regulations

- Wearing appropriate personal protective equipment (PPE)

- Maintaining a clean and organized work area

Interview Tips

To ace the interview for a Machine Buffer position, it is important to be well-prepared. Here are some tips and hacks:

1. Research the Company and Role

Before the interview, take the time to research the company and the specific role you are applying for. This will help you understand the company’s values, culture, and the expectations for the position.

- Visit the company’s website and read about their history, mission, and products or services.

- Look up industry news and articles to demonstrate your knowledge of the field.

2. Practice Your Answers

Take some time to think about the common interview questions you may be asked and practice your answers. This will help you feel more confident and prepared during the actual interview.

- Review the job description and identify the key skills and experience required.

- Prepare specific examples from your previous work experience that demonstrate your abilities.

- Practice answering questions using the STAR method (Situation, Task, Action, Result).

3. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role.

- Prepare questions about the company’s plans for future growth.

- Ask about opportunities for professional development and training.

- Inquire about the company’s work culture and values.

4. Dress Professionally and Arrive on Time

First impressions matter, so make sure to dress professionally and arrive on time for your interview. This shows that you respect the company and the interviewer’s time.

- Choose clothing that is clean, pressed, and appropriate for a manufacturing environment.

- Arrive at the interview location at least 10 minutes early to give yourself enough time to check in.

Next Step:

Now that you’re armed with the knowledge of Machine Buffer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Machine Buffer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini