Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Machine Stone Polisher interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Machine Stone Polisher so you can tailor your answers to impress potential employers.

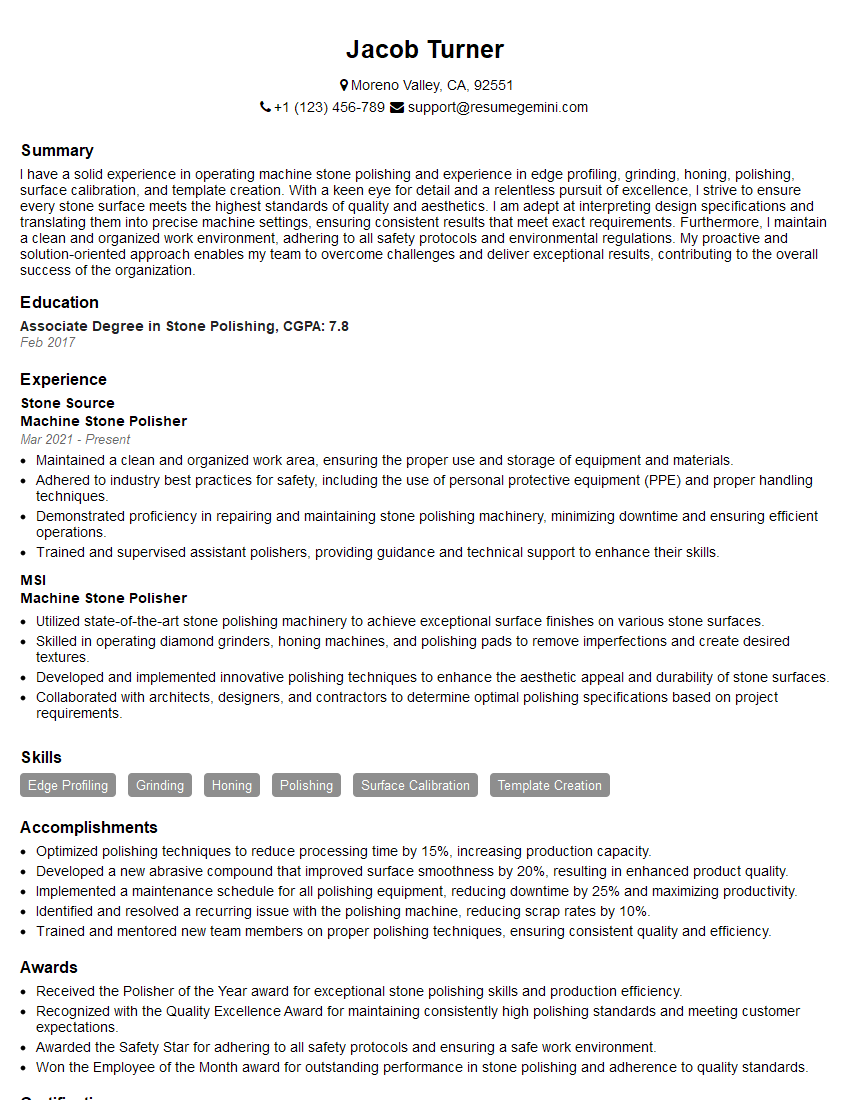

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Stone Polisher

1. Explain the different types of stone polishing machines and their uses?

- Floor Polishers: Used to polish large areas of stone flooring.

- Benchtop Polishers: Smaller machines used for polishing smaller stone surfaces, such as countertops.

- Handheld Polishers: Portable machines used for spot-polishing or polishing hard-to-reach areas.

- Wet Polishers: Use water as a lubricant to achieve a wet polish, resulting in a smoother finish.

- Dry Polishers: Use no water or lubricants, resulting in a drier, less glossy finish.

2. What are the key factors to consider when selecting abrasives for stone polishing?

Abrasive Type

- Diamond abrasives: Excellent for hardness and durability, suitable for rough polishing.

- Silicon carbide abrasives: Provide a finer finish than diamond abrasives, suitable for intermediate polishing.

- Aluminum oxide abrasives: Best for fine polishing, resulting in a smooth, glossy finish.

Abrasive Grit

- Low grit abrasives (e.g., 50-100) for removing scratches and leveling the surface.

- Medium grit abrasives (e.g., 200-400) for intermediate polishing and smoothing.

- High grit abrasives (e.g., 800-1200) for final polishing and achieving a high gloss.

3. Describe the process of honing a stone surface?

- Prepare the surface: Clean the surface and remove any existing sealants or coatings.

- Use a honing powder: Apply honing powder to the surface using a felt pad or buffing wheel.

- Lubricate the surface: Add water to the surface to act as a lubricant and prevent the powder from scratching the surface.

- Buff the surface: Use a honing machine or handheld buffer to work the powder into the surface in circular motions.

- Rinse and dry: Rinse the surface thoroughly with clean water and allow it to dry completely.

4. Explain the difference between honing and polishing a stone surface?

- Honing: Removes scratches and levels the surface, resulting in a matte or slightly textured finish.

- Polishing: Produces a smooth, glossy finish by filling in the pores of the stone with a polishing compound.

5. What are the common causes of streaks or haze on a polished stone surface?

- Uneven pressure: Applying too much or too little pressure during polishing can create streaks.

- Dirty pads or buffs: Using dirty or contaminated pads can transfer dirt or debris onto the surface.

- Improper use of sealants: Applying sealants before the surface is completely dry or using the wrong type of sealant can cause haze.

- Incorrect abrasive selection: Using abrasives that are too coarse or too fine can result in streaks or haze.

6. How can you prevent scratching or damage to a stone surface during polishing?

- Use the correct abrasives: Select abrasives that are appropriate for the stone type and desired finish.

- Apply even pressure: Maintain a consistent pressure when polishing to avoid uneven wear.

- Keep the surface wet: Use water or a polishing lubricant to minimize friction and prevent scratching.

- Change pads or buffs regularly: Avoid using dirty or worn pads or buffs that can contain abrasive particles.

- Test on an inconspicuous area: Always test the polishing process on a small, inconspicuous area before proceeding with the entire surface.

7. What are the different types of finishes that can be achieved on a stone surface?

- Honed: Matte or low-sheen finish with a slightly textured surface.

- Polished: Smooth, glossy finish with a high sheen.

- Satin: Semi-gloss finish with a subtle sheen.

- Aged: Finish that resembles the appearance of weathered or antique stone.

- Brushed: Finish with a rough, textured surface created using a wire brush.

8. How do you determine the condition of a stone surface and assess its need for polishing?

- Visual inspection: Look for scratches, stains, or other signs of wear.

- Water absorption test: Drop water onto the surface. If it absorbs quickly, the surface may need sealing or polishing.

- Acid test: Apply a small amount of acid (e.g., vinegar) to the surface. If it reacts, the stone may be susceptible to staining or damage and may need polishing.

9. Explain the importance of sealing a stone surface after polishing?

- Protects against stains: Sealants fill in the pores of the stone, preventing liquids and stains from penetrating.

- Prevents damage from moisture: Seals prevent moisture from seeping into the stone, reducing the risk of cracking or erosion.

- Enhances appearance: Sealants can enhance the color and sheen of the stone, making it look more vibrant.

10. What are the different types of sealants used for stone surfaces and their advantages and disadvantages?

Penetrating Sealants

- Advantages: Invisible, breathable, and provide long-lasting protection.

- Disadvantages: Can be more expensive and require reapplication over time.

Topical Sealants

- Advantages: Easy to apply and provide a durable, protective layer.

- Disadvantages: Can alter the appearance of the stone and may need to be reapplied more frequently.

Impregnating Sealants

- Advantages: Deeply penetrate the stone and provide excellent protection against stains and moisture.

- Disadvantages: Can be more difficult to apply and may require professional installation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Stone Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Stone Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Preparing Stone Surfaces for Polishing

Prior to polishing, stone surfaces need to be properly prepared to ensure optimal results. This includes removing any existing coatings, leveling uneven surfaces, and repairing any cracks or chips.

- Using tools like grinders and rotary hammers to level surfaces and remove coatings

- Applying fillers and patching compounds to repair cracks and chips

2. Operating Stone Polishing Machines

Once the surface is prepared, a variety of polishing machines are used to achieve the desired finish. These machines may include grinders, polishers, and buffers.

- Selecting the appropriate grinding stones, polishing pads, and abrasives for the type of stone being polished

- Operating machines correctly to avoid surface damage

3. Polishing and Finishing Stone Surfaces

The actual polishing process involves using abrasives and polishing compounds to gradually smooth and refine the surface.

- Applying polishing compounds and abrasives to the surface

- Using machines to polish the surface to the desired level of gloss

4. Maintaining and Cleaning Equipment

To ensure optimal performance and longevity, the proper maintenance and cleaning of equipment is essential.

- Cleaning and inspecting equipment regularly

- Performing basic maintenance tasks such as changing brushes and pads

Interview Tips

Preparing for a job interview can be a daunting task. However, by following these tips, candidates can increase their chances of success.

1. Research the Company and the Position

Before the interview, take the necessary steps to learn as much as possible about the company and the specific position you are applying for. This will help you to better understand the company’s culture, values, and goals.

- Visit the company’s website

- Read industry-related publications

- Network with people in your field

2. Practice Your Answers to Common Interview Questions

There are several common interview questions that you can expect to be asked. By practicing your answers beforehand, you can ensure that you are well-prepared to respond in a clear and concise manner.

- Tell me about yourself.

- Why are you interested in this position?

- Why should we hire you?

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of the interview shows that you are interested and engaged. It also gives you an opportunity to learn more about the company and the position.

- What are the company’s goals for the next year?

- What is the company culture like?

- What is the biggest challenge facing the company right now?

4. Dress Professionally and Arrive on Time

First impressions matter. Make sure to dress appropriately for the interview and arrive on time. This shows that you are respectful of the interviewer’s time and that you are taking the interview seriously.

Remember, the key to a successful interview is preparation. Especially in technical fields, like machine stone polishing, the candidate’s knowledge and expertise will be put to test. Be confident, articulate and showcase your skills and experience to stand out and ace the interview.Next Step:

Now that you’re armed with the knowledge of Machine Stone Polisher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Machine Stone Polisher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini