Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Plate Glass Grinder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Plate Glass Grinder so you can tailor your answers to impress potential employers.

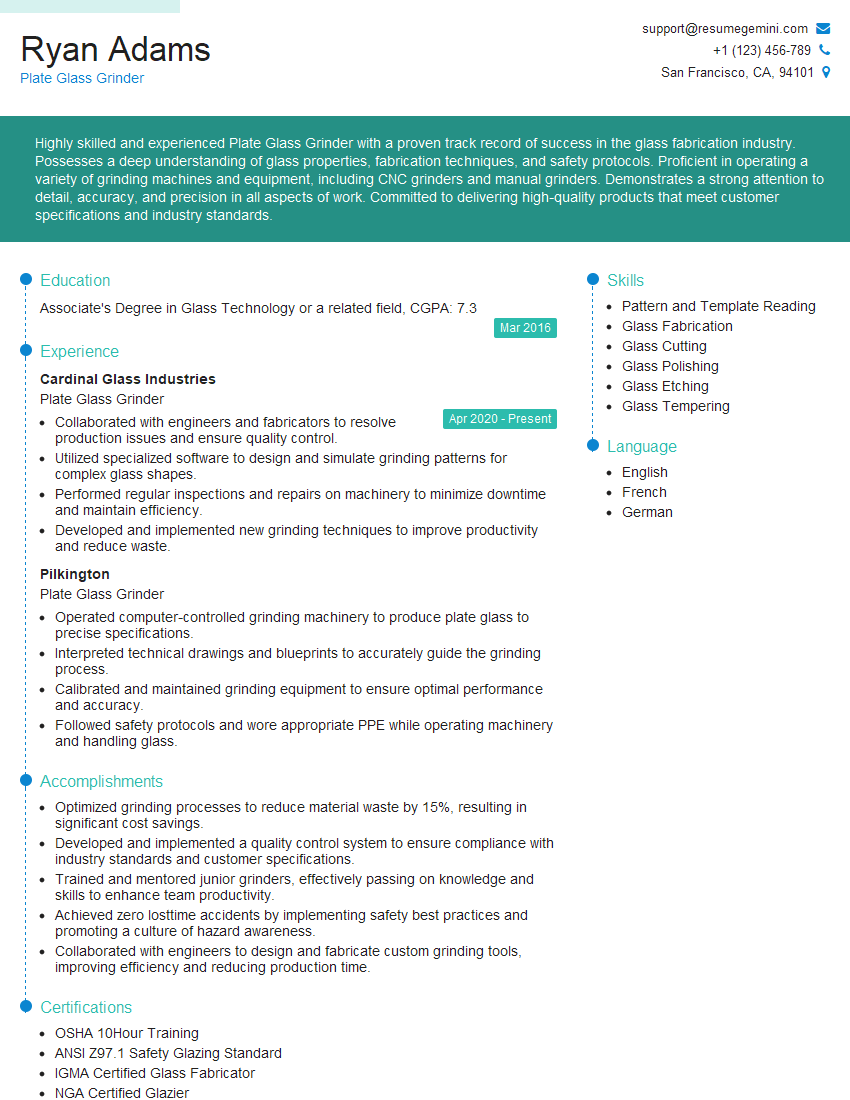

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plate Glass Grinder

1. Explain the different types of glass grinding machines and their uses?

- Plate glass grinders: Used for grinding and shaping large flat pieces of glass, such as those used in windows and mirrors.

- Belt grinders: Use abrasive belts to grind and finish the edges of glass.

- Edge grinders: Designed specifically to create beveled edges on glass.

- Surface grinders: Use flat abrasive wheels to grind and level the surfaces of glass.

- CNC grinders: Computer-controlled machines that offer high precision and accuracy in grinding operations.

2. Describe the safety precautions that must be taken when operating a plate glass grinder?

Personal Protective Equipment (PPE)

- Safety glasses

- Gloves

- Hearing protection

- Respirator (if necessary)

Machine Safety

- Ensure the machine is properly grounded.

- Inspect the machine regularly for any damage or loose parts.

- Never operate the machine with missing or damaged guards.

- Always secure the glass properly before grinding.

- Avoid touching the grinding wheels while they are in operation.

3. How do you determine the correct grit size for grinding a particular type of glass?

- Consider the hardness of the glass.

- Coarse grits (e.g., 36-80) are used for removing large amounts of material quickly.

- Medium grits (e.g., 100-220) are used for general grinding and shaping.

- Fine grits (e.g., 320-600) are used for finishing and polishing.

- Consult with the glass manufacturer or a grinding specialist for specific recommendations.

4. Explain the importance of maintaining proper water flow during glass grinding?

- Cooling: Water acts as a coolant, preventing the glass from overheating and cracking.

- Lubrication: Water helps lubricate the grinding wheels, reducing friction and wear.

- Removal of debris: Water flushes away glass particles and debris, preventing them from clogging the grinding wheels.

- Improved surface finish: Proper water flow helps achieve a smoother and more polished surface on the glass.

5. Describe the process of polishing the edges of a glass pane?

- Start with a coarse grit grinding wheel to remove any unevenness or sharp edges.

- Gradually switch to finer grit wheels to refine the shape and surface of the edge.

- Use a polishing pad and polishing compound to bring the edge to a high gloss finish.

- Inspect the polished edge for any imperfections and correct as necessary.

6. How do you handle and store glass sheets safely to prevent breakage or damage?

- Wear gloves and protective clothing.

- Use a glass rack or suction cups to handle large sheets.

- Store glass sheets vertically in a secure and well-supported rack.

- Avoid stacking glass sheets directly on top of each other.

- Protect glass sheets from moisture, extreme temperatures, and sharp objects.

7. Explain how you troubleshoot common problems encountered during plate glass grinding?

- Chattering: Adjust the grinding wheel speed or use a finer grit.

- Burn marks: Reduce the grinding pressure or speed, and ensure proper water flow.

- Uneven grinding: Check the alignment of the grinding wheel and glass holder.

- Glass breaks during grinding: Inspect the glass for cracks or defects, and use a lower grinding pressure.

- Poor surface finish: Use a finer grit wheel, increase water flow, or adjust the polishing technique.

8. Describe your experience with operating CNC glass grinding machines?

- Explain how you set up and program the CNC machine.

- Discuss the different types of grinding operations you have performed using CNC.

- Highlight any specific features or capabilities of the CNC machines you have used.

- Quantify your experience in operating CNC glass grinding machines (e.g., number of hours or projects completed).

9. How do you stay updated on the latest advancements in glass grinding technology?

- Attend industry conferences and exhibitions.

- Read technical journals and articles.

- Consult with equipment manufacturers and suppliers.

- Participate in online forums and discussion groups.

- Take courses or workshops on glass grinding techniques.

10. What are your career goals as a Plate Glass Grinder?

- Express your passion for glass grinding and craftsmanship.

- Describe your desire to develop your skills and knowledge in this field.

- Discuss your career aspirations, such as becoming a lead grinder or starting your own glass grinding business.

- Explain how this role aligns with your career goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plate Glass Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plate Glass Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Plate Glass Grinders are responsible for operating machinery that shapes and polishes plate glass. They typically follow blueprints or instructions to create custom glass pieces for various applications.

1. Operating Machinery

Grinders operate a range of machines, including grinders, polishers, and saws, to shape and finish glass.

- Set up and operate machines according to specifications

- Adjust machine settings to achieve desired results

2. Measuring and Cutting Glass

Grinders measure and cut glass to create custom pieces for various applications.

- Read and interpret blueprints or instructions

- Measure and mark glass for cutting

- Cut glass using a variety of tools and techniques

3. Grinding and Polishing Glass

Grinders grind and polish glass to achieve a smooth and polished finish.

- Grind glass to remove imperfections and create a smooth surface

- Polish glass to achieve a glossy finish

4. Inspecting and Packaging Glass

Grinders inspect finished glass pieces to ensure they meet specifications and package them for shipment.

- Inspect glass for defects and imperfections

- Package glass for shipment

Interview Tips

To ace a plate glass grinder interview, candidates should highlight their technical skills and experience, as well as their attention to detail and ability to work independently.

1. Research the Company and Industry

Learn about the company’s products, services, and values, as well as the latest trends in the glass industry.

- Visit the company’s website and social media pages

- Read industry publications and articles

2. Prepare Questions

Asking thoughtful questions demonstrates your interest and engagement. Prepare questions about the company, the role, and the industry.

- What are the company’s growth plans?

- What are the key challenges facing the industry?

3. Emphasize Your Skills and Experience

Highlight your technical skills and experience in glass grinding and polishing. Quantify your accomplishments whenever possible.

- Use the STAR method to answer behavioral questions

- Provide specific examples of your work

4. Be Prepared to Discuss Your Career Goals

Demonstrate your ambition and drive by discussing your career goals. Explain how the role aligns with your aspirations.

- Share your short-term and long-term career goals

- Explain how the role can help you achieve your goals

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Plate Glass Grinder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Plate Glass Grinder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.