Feeling lost in a sea of interview questions? Landed that dream interview for Pulper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Pulper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

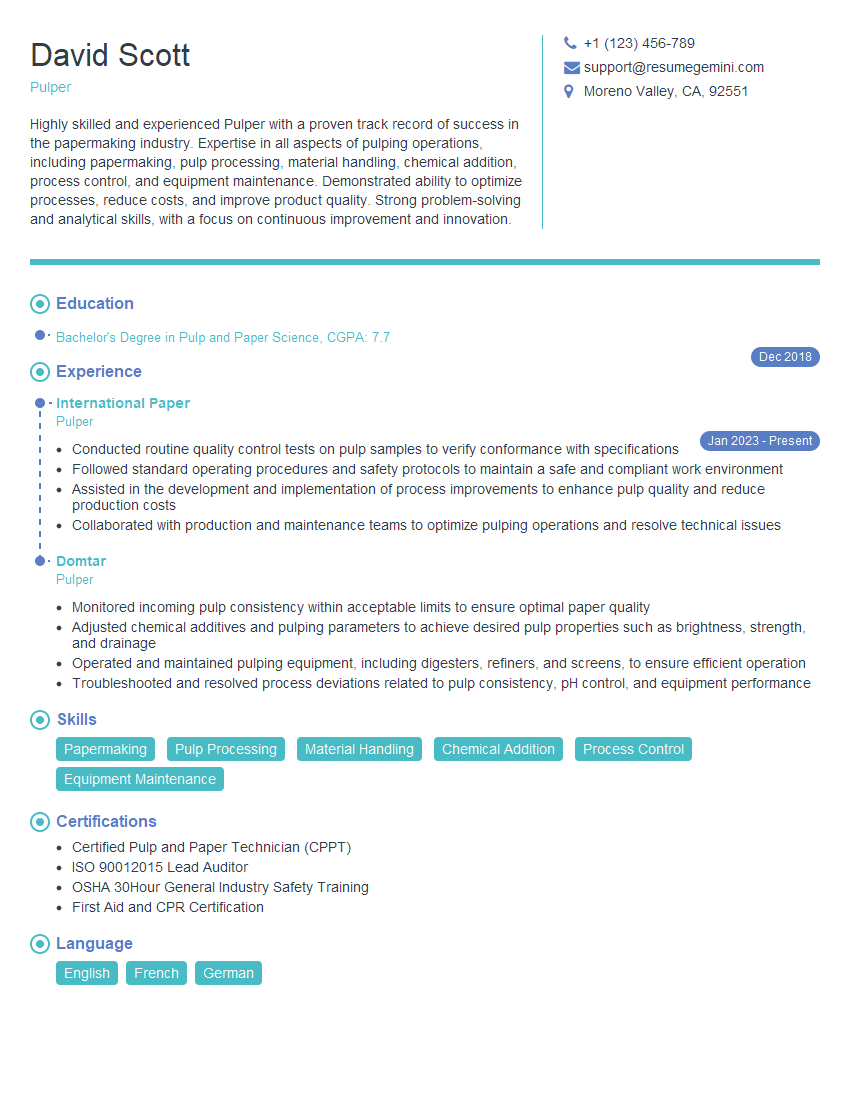

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pulper

1. Explain the process of pulp refining?

- Pulping: Breaking down wood chips into individual fibers using mechanical, chemical, or a combination of both methods.

- Screening: Removing oversized fibers, knots, and other debris from the pulp.

- Cleaning: Removing contaminants such as bark, dirt, and sand.

- Bleaching: Brightening the pulp and removing lignin (a dark-colored compound).

- Refining: Breaking down and cutting the fibers to achieve desired properties, such as strength, absorbency, and texture.

2. What types of refiners are commonly used in the pulp and paper industry?

Conical refiners

- High-consistency operation (up to 15% fiber consistency)

- Excellent for fiber development and producing long, strong fibers

Disc refiners

- Medium-consistency operation (3-5% fiber consistency)

- Versatile, used for a wide range of applications from coarse to fine refining

Drum refiners

- Low-consistency operation (up to 2% fiber consistency)

- Gentle on fibers, suitable for producing soft, low-strength papers

3. What factors influence the degree of pulp refining?

- Type of refining equipment

- Plate pattern and gap setting of refiners

- Pulp consistency

- Temperature and pH

- Species and quality of wood fibers

4. How do you determine the optimal refining level for a specific paper grade?

By performing laboratory tests and evaluating pulp properties such as:

- Freeness (drainage rate)

- Tensile strength

- Tear strength

- Brightness

- Opacity

5. What are the benefits of using high-consistency refiners?

- Increased energy efficiency

- Improved fiber development and fibrillation

- Reduced fiber breakage

- Increased production capacity

6. How do you maintain and troubleshoot pulping and refining equipment?

- Regular inspections and preventive maintenance

- Monitoring equipment performance and identifying deviations

- Troubleshooting common issues, such as plate wear, bearing failures, and hydraulic leaks

- Working with technical support from equipment manufacturers

7. What are some emerging technologies in the pulping and refining industry?

- Twin-wire forming

- Ultra-high consistency refining

- Hydrodynamic cavitation

- Enzyme-assisted pulping

- Biopulping

8. How do you optimize the refining process for different paper grades?

By understanding the desired properties of each paper grade and adjusting refining parameters accordingly, such as:

- Plate pattern

- Gap setting

- Residence time

- Pulp consistency

- Chemical additives

9. How do you ensure the quality of the pulp after refining?

- Performing regular laboratory tests to monitor pulp properties

- Implementing a quality control system to track and adjust refining parameters

- Collaborating with other departments to ensure consistency throughout the papermaking process

10. How do you stay up-to-date with the latest trends and technologies in the pulping and refining industry?

- Attending industry conferences and workshops

- Reading technical publications and journals

- Networking with colleagues and experts

- Participating in research and development projects

- Collaborating with equipment manufacturers

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pulper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pulper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pulp mill operators, also known as pulpers, play a crucial role in the papermaking process by converting wood chips into pulp, the primary raw material for paper production. Their responsibilities encompass various aspects of the pulping operation, ensuring efficient and high-quality pulp production.

1. Pulp Production

Maintains and operates pulp digesters and cooking systems to convert wood chips into pulp

- Monitors and adjusts process parameters, such as temperature, pressure, and chemical concentrations, to optimize pulp yield and quality

- Ensures proper mixing of wood chips and chemicals, promoting uniform cooking and pulp properties

2. Pulp Washing and Screening

Operates washing equipment to remove spent chemicals and impurities from the pulp

- Monitors and controls the washing process to achieve desired pulp cleanliness and brightness

- Screens pulp to remove oversized particles, knots, and other contaminants

3. Pulp Testing and Analysis

Conducts regular pulp testing to evaluate its quality and consistency

- Measures pulp properties, such as moisture content, fiber length, and brightness, using standardized testing methods

- Identifies any deviations from specifications and makes necessary adjustments to the pulping process

4. Equipment Maintenance and Troubleshooting

Performs routine maintenance and repairs on pulping equipment

- Inspects and cleans equipment regularly to prevent breakdowns and ensure smooth operation

- Troubleshoots and repairs malfunctions, ensuring efficient pulp production and minimizing downtime

Interview Tips

Preparing for a pulper interview requires a combination of technical knowledge, industry awareness, and effective interview skills. Here are some tips and hacks to help candidates ace their interviews:

1. Research the Company and Role

Familiarize yourself with the company’s history, products, and operations. Research the specific role you’re applying for, paying attention to its responsibilities and required qualifications.

- This knowledge will demonstrate your interest in the position and the company, making you appear more engaged and interested.

- You can find relevant information on the company’s website, LinkedIn page, and industry publications.

2. Practice Common Interview Questions

Anticipate common interview questions related to pulping operations, equipment maintenance, and quality control. Practice answering these questions clearly and concisely, highlighting your relevant skills and experience.

- Common questions may include: “Describe your experience in pulp production,” “What are the key factors to consider when optimizing pulp yield,” or “How do you troubleshoot equipment malfunctions.”

- Prepare specific examples that demonstrate your problem-solving abilities and technical expertise.

3. Demonstrate Your Technical Skills

Emphasize your technical knowledge and skills related to pulping operations. Explain your understanding of the pulping process, including different cooking methods, washing techniques, and quality control measures.

- Share examples of how you have used your technical expertise to improve pulp quality, increase efficiency, or reduce downtime.

- Be prepared to discuss industry best practices and recent advancements in pulping technology.

4. Highlight Your Problem-Solving Abilities

Pulpers often encounter unexpected situations and equipment malfunctions. Showcase your problem-solving abilities by providing examples of how you have identified and resolved issues in the past.

- Describe your analytical approach to troubleshooting and how you prioritized tasks to minimize production disruptions.

- Explain how you worked with colleagues and supervisors to find effective solutions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pulper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!