Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Center Hole Reamer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

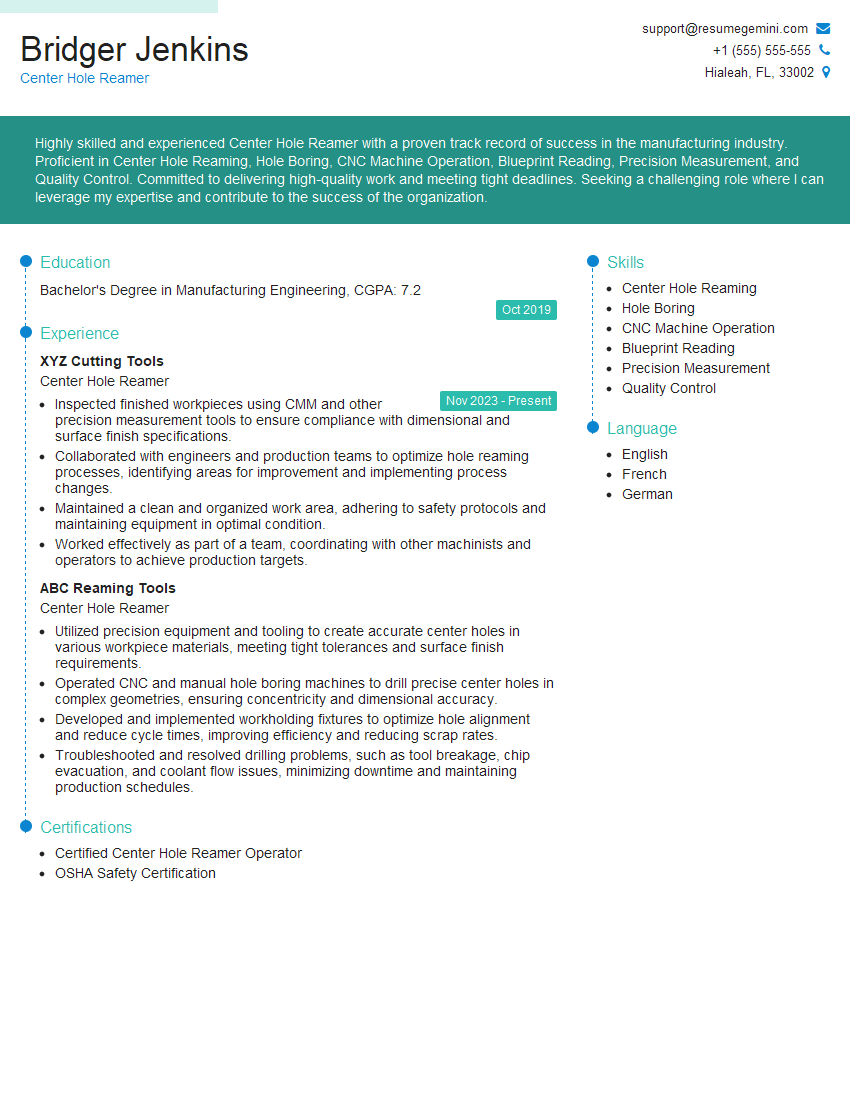

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Center Hole Reamer

1. What are the key specifications and applications of a Center Hole Reamer?

Key Specifications:

- Diameter: The diameter of the hole to be reamed.

- Length: The overall length of the reamer.

- Flute Length: The length of the cutting flutes.

- Number of Flutes: The number of cutting flutes on the reamer.

- Material: The material used to construct the reamer, such as HSS, carbide, or cobalt.

Applications:

- Enlarging existing holes.

- Finishing existing holes to precise dimensions and surface finishes.

- Creating a pilot hole for a larger drill.

- Repairing damaged holes.

2. Explain the different types of Center Hole Reamers and their advantages and disadvantages.

Hand Reamers:

- Hand-held devices for low-volume applications.

- Advantages: Simple and inexpensive.

- Disadvantages: Manual operation limits precision and efficiency.

Machine Reamers:

- Designed for high-volume applications and provide greater precision.

- Advantages: Fast and accurate.

- Disadvantages: More expensive and require specialized machinery.

Taper-Pin Reamers:

- Used for reaming holes that need to be slightly tapered.

- Advantages: Create a gradual transition between two different hole diameters.

- Disadvantages: Not suitable for reaming large holes.

Chucking Reamers:

- Mounted in a chuck for use in machine tools.

- Advantages: High precision and efficiency.

- Disadvantages: Require a chuck and may be more expensive.

3. How do you select the correct Center Hole Reamer for a specific application?

- Consider the material being reamed.

- Determine the desired hole diameter and surface finish.

- Choose a reamer with the appropriate number of flutes for the material and hole size.

- Select a reamer with the correct length for the required depth of cut.

- Choose a reamer with the appropriate shank size for the machine tool or chuck.

4. What are the common causes of Center Hole Reamer failure?

- Using the wrong reamer for the material or hole size.

- Insufficient lubrication.

- Excessive feed rates or spindle speeds.

- Poor tool maintenance (e.g., dull cutters).

- Machine tool problems (e.g., vibration, chatter).

5. How do you maintain Center Hole Reamers for optimal performance?

- Clean and inspect reamers after each use.

- Sharpen cutters as needed.

- Properly lubricate reamers during use.

- Store reamers in a dry and safe place.

- Follow manufacturer’s instructions for maintenance and replacement.

6. Explain the importance of lubrication when using Center Hole Reamers.

- Reduces friction and wear on the reamer and workpiece.

- Improves surface finish of the reamed hole.

- Helps remove chips and debris from the cutting zone.

- Extends the life of the reamer.

7. What factors affect the feed rate of a Center Hole Reamer?

- Material being reamed.

- Diameter and length of the reamer.

- Spindle speed of the machine tool.

- Condition of the reamer (e.g., sharpness).

- Required surface finish.

8. How do you ensure the accuracy and precision of a Center Hole Reaming operation?

- Use a properly calibrated measuring instrument to measure the diameter of the hole.

- Ensure the reamer is aligned with the hole to be reamed.

- Use a vise or fixture to hold the workpiece securely.

- Apply proper lubrication and cutting parameters.

- Monitor the operation for any signs of chatter or vibration.

9. Describe the safety precautions that should be taken when using Center Hole Reamers.

- Wear appropriate personal protective equipment (PPE).

- Ensure the machine tool is properly guarded.

- Keep hands and loose clothing away from the cutting zone.

- Stop the machine immediately if any unusual noises or vibrations occur.

- Follow all instructions provided by the manufacturer.

10. What are the latest developments and trends in Center Hole Reaming technology?

- Development of new materials for reamers, such as nano-structured coatings and super-hard alloys.

- Use of advanced manufacturing techniques, such as CNC grinding and laser cutting.

- Integration of sensors and data analytics for real-time monitoring and optimization.

- Development of automated reaming systems for high-volume applications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Center Hole Reamer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Center Hole Reamer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The role of a Center Hole Reamer is to ensure the accuracy and precision of reaming operations in metalworking. Key responsibilities include:1. Operate and maintain reaming machines:

Setup, calibrate, and operate reaming machines according to established procedures. Maintain and troubleshoot machines to ensure optimal performance and prevent breakdowns.

2. Select and use appropriate reamers and cutting tools:

Choose the correct reamers and cutting tools based on material type, hole size, and required tolerances. Ensure tools are sharp and in good working order.

3. Measure and inspect reamed holes:

Use precision measuring instruments to verify the accuracy of reamed holes and ensure they meet specified tolerances. Inspect holes for defects, such as burrs, chatter marks, or out-of-roundness.

4. Adhere to safety protocols:

Wear appropriate personal protective equipment and follow established workplace safety procedures to minimize risks associated with reaming operations.

Interview Tips

To ace an interview for a Center Hole Reamer position, consider the following tips:1. Research the company and position:

Familiarize yourself with the company’s industry, products, and services. Understand the specific responsibilities and requirements of the Center Hole Reamer position.

2. Highlight your technical skills:

Emphasize your proficiency in operating and maintaining reaming machines. Showcase your knowledge of different types of reamers, cutting tools, and measuring instruments.

3. Demonstrate attention to detail:

Provide examples of how you have consistently met or exceeded quality standards in your previous roles. Highlight your ability to work accurately and precisely to achieve desired results.

4. Prepare for common interview questions:

Anticipate questions related to your experience with reaming operations, your understanding of industry standards, and your commitment to safety. Prepare thoughtful answers that showcase your knowledge and enthusiasm for the role.

Next Step:

Now that you’re armed with the knowledge of Center Hole Reamer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Center Hole Reamer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini